Product Details

The quest for cleaner, more efficient energy solutions has led to the development of innovative technologies that aim to reduce our dependency on fossil fuels. One such breakthrough is the hydrogen humidifier high porosity high-efficiency titanium sintered felt, an essential component in fuel cell systems. This technological marvel combines cutting-edge material science with sophisticated engineering to enhance the performance and efficiency of hydrogen fuel cells.

What is a Hydrogen Fuel Cell?

A hydrogen fuel cell is an electrochemical device that converts the chemical energy stored in hydrogen into electrical energy through a reaction with oxygen, typically from the air. Water vapor is the only emission, making fuel cells an environmentally friendly alternative to combustion engines. Fuel cells are used in various applications, including vehicles, portable power units, and stationary power generation systems.

The Role of a Humidifier in Fuel Cells

Humidification plays a crucial role in the operation of proton exchange membrane (PEM) fuel cells, a common type of fuel cell. The membrane within the fuel cell requires moisture to maintain its ionic conductivity, which facilitates the flow of protons from the anode to the cathode. Without proper humidification, the membrane can become brittle and less permeable, leading to reduced efficiency and potential failure of the fuel cell.

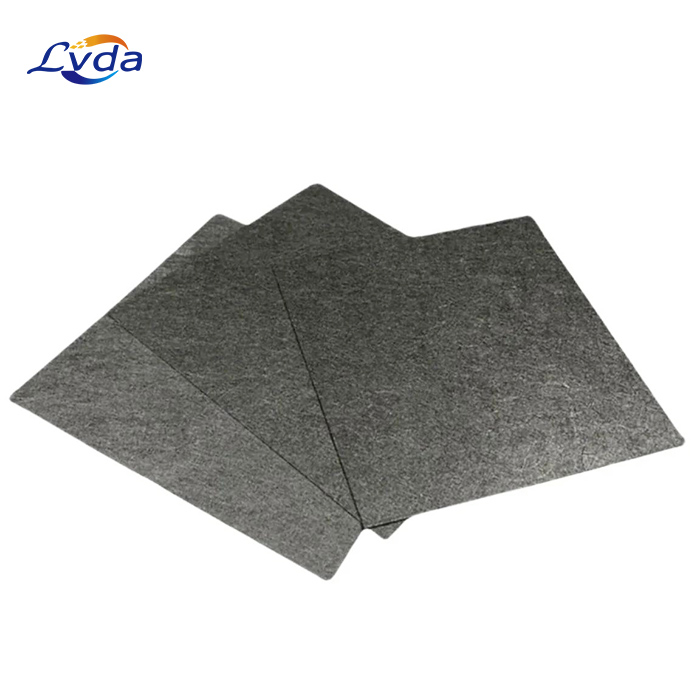

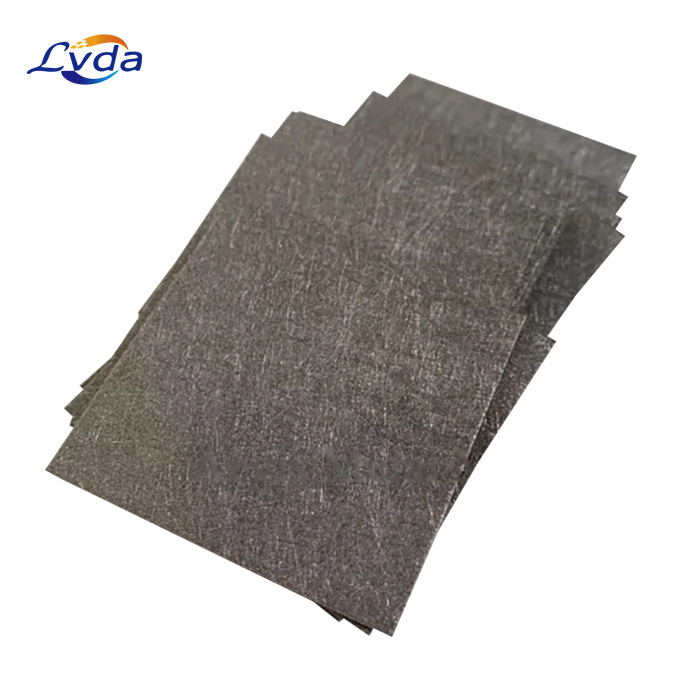

Introducing the Titanium Sintered Felt

The titanium sintered felt is a key component in the humidification system of PEM fuel cells. It is a porous material made by sintering titanium fibers together at high temperatures. The result is a strong, durable, and highly porous structure that provides an ideal surface for water vapor to condense and for gases to diffuse efficiently.

High Porosity and Efficiency

The high porosity of the titanium sintered felt allows for increased surface area, which enhances the rate of heat and mass transfer. This leads to more efficient water management within the fuel cell, ensuring that the membrane remains adequately hydrated. The unique microstructure also minimizes pressure drops across the felt, reducing the energy required to force gases through the material.

Material Advantages

Titanium is chosen for its exceptional corrosion resistance, lightweight properties, and high strength-to-weight ratio. In a hydrogen environment, these characteristics are paramount to ensure longevity and reliability. The sintered felt's resistance to chemicals and high temperatures makes it suitable for use in harsh operating conditions.

Manufacturing Process

The manufacturing process of the titanium sintered felt involves blending titanium fibers, followed by compression and sintering in a controlled atmosphere. The sintering process bonds the fibers together without melting them, creating a stable and consistent porous structure. The final product can be tailored to specific requirements by adjusting the fiber diameter, pore size, and overall thickness.

Integration into Fuel Cell Systems

The high porosity high-efficiency titanium sintered felt is integrated into the humidification system of PEM fuel cells. It is often situated within the gas diffusion layer, where it aids in the distribution of gases and the removal of excess moisture. Its presence ensures that the fuel cell operates at peak efficiency by maintaining the necessary humidity levels within the membrane.

Performance Enhancements

The use of this advanced titanium sintered felt has been shown to improve the overall performance of fuel cells. It results in higher power density, lower operational costs, and extended lifetimes of the fuel cell components. These enhancements make fuel cell technology more competitive with traditional energy sources and accelerate its adoption in various markets.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português