Product Details

Hydrogen generators, often associated with the process of electrolysis, play a crucial role in producing hydrogen gas, which has wide-ranging applications in various industries, including energy, transportation, and healthcare. One of the key components that contribute to the efficiency and effectiveness of these generators is porous titanium felt.

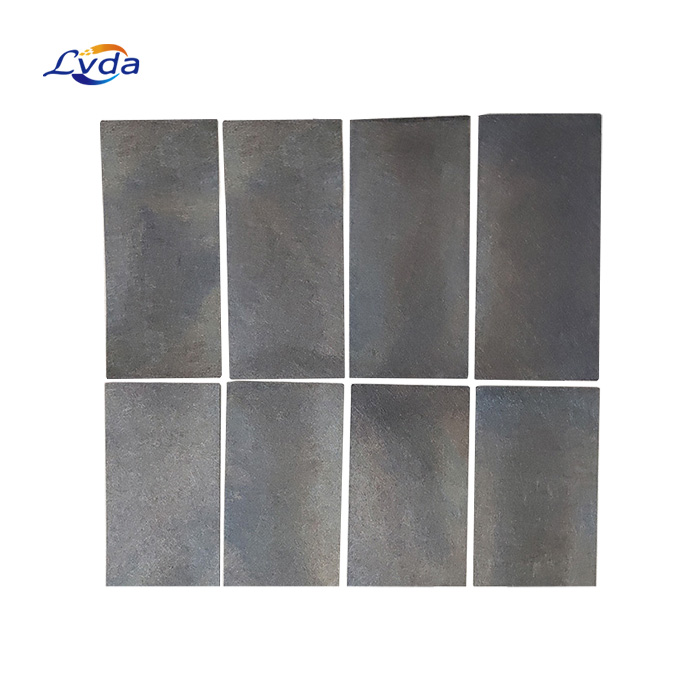

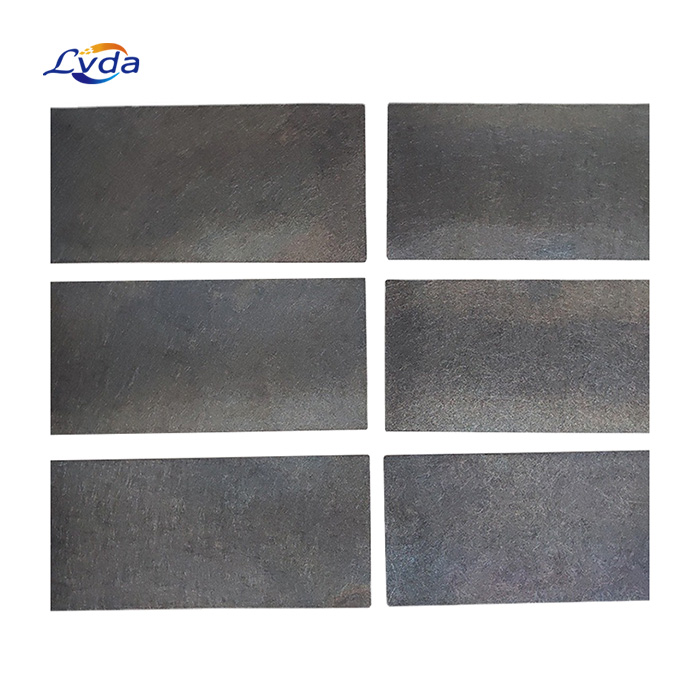

Titanium felt, characterized by its unique porous structure, is a high-performance material made from fine titanium fibers. These fibers are woven or needled together to create a strong, durable, and lightweight material with excellent chemical resistance and thermal stability. The porosity of the felt allows for high surface area availability, making it an ideal candidate for use in hydrogen generators.

Role of Porous Titanium Felt in Hydrogen Generation: Porous titanium felt finds significant application in hydrogen generators, particularly in the production of high-purity hydrogen gas. Its excellent chemical stability and resistance to corrosion make it an ideal material for use in electrolyzers, which are commonly used in hydrogen generation. The felt-like structure of porous titanium facilitates the efficient diffusion of reactants and products, thereby enhancing the overall efficiency of the electrolysis process.

Pure Hydrogen Production: One of the key advantages of using porous titanium felt in hydrogen generators is its ability to produce high-purity hydrogen gas. The porous structure of the titanium felt allows for the adsorption and separation of impurities, resulting in a cleaner and more pure hydrogen gas output. This is particularly important in applications where the purity of hydrogen gas significantly impacts the performance and lifespan of downstream fuel cells or other hydrogen-based technologies.

Catalyst Support Material: Porous titanium felt can also serve as an excellent catalyst support material in certain hydrogen generation processes. Its high surface area and uniform pore structure provide an ideal platform for the deposition and dispersion of catalysts. This, in turn, enhances the catalytic activity and efficiency of the hydrogen generation process, contributing to the overall production of hydrogen gas.

Thermal Management: The good thermal conductivity of porous titanium felt makes it an effective material for thermal management in hydrogen generators. The felt can act as a heat sink or a heat exchanger, dissipating excess heat and maintaining stable operating temperatures. This is crucial for the efficient and safe operation of the hydrogen generator, as excessive heat can lead to reduced performance and potential hazards.

Corrosion-Resistant Components: The corrosion-resistant properties of porous titanium felt make it suitable for use in corrosive environments commonly encountered in hydrogen generation systems. The felt can be used to fabricate various components, such as electrodes, separators, and liners, which are exposed to harsh chemical environments. By utilizing porous titanium felt, the lifespan of these components can be significantly extended, reducing maintenance costs and ensuring reliable operation of the hydrogen generator.

Porous titanium felt plays a critical role in hydrogen generators, particularly in proton exchange membrane (PEM) electrolyzers, which are commonly used for hydrogen production. Here are some of its primary applications:

Gas diffusion layer: In PEM electrolyzers, porous titanium felt serves as the gas diffusion layer (GDL), providing a pathway for the transport of gaseous reactants (oxygen and hydrogen) to and from the catalyst layers.

Current collector: The felt also acts as a current collector, distributing the electrical current evenly across the electrode surfaces and reducing ohmic losses within the system.

Catalytic support: In some cases, porous titanium felt may be coated with a catalyst material, such as iridium or platinum, to enhance the electrochemical reaction rates at the electrode surfaces.

Mechanical support: The felt provides mechanical support to the electrode assembly, maintaining its structural integrity under the pressure and temperature conditions present during operation.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português