Product Details

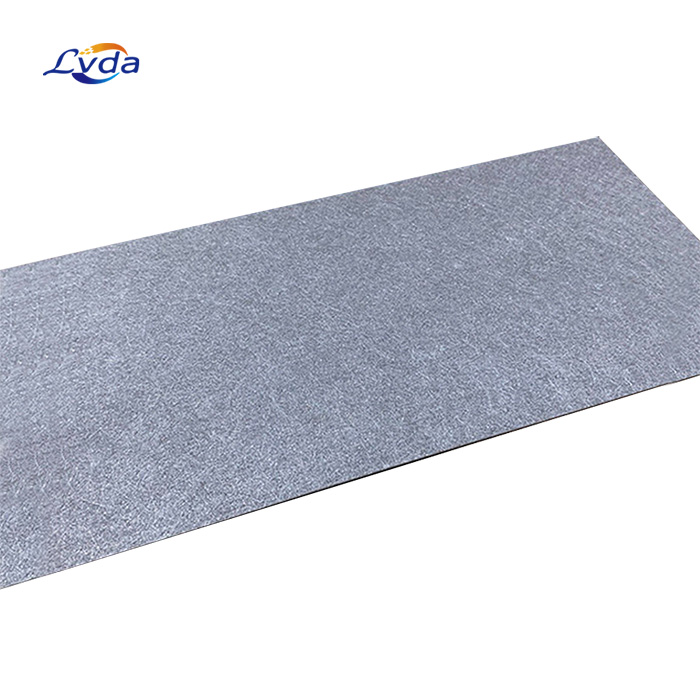

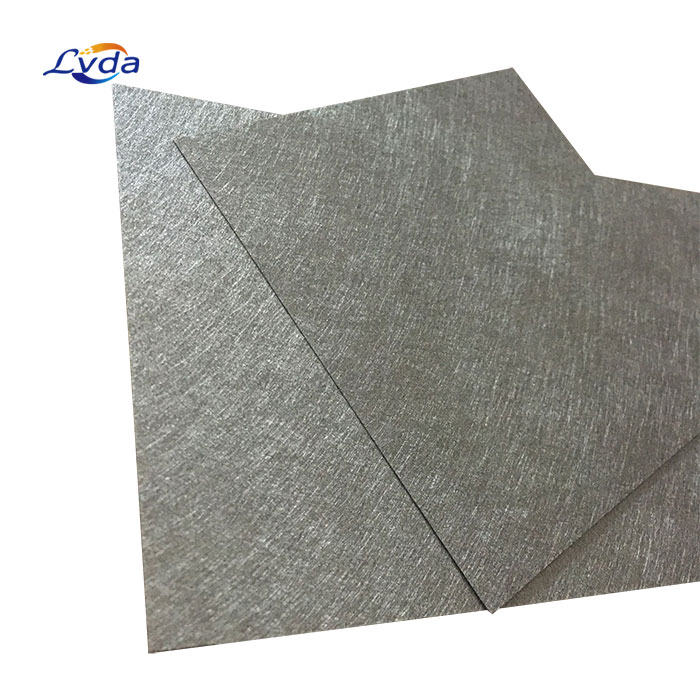

The High Strength Metal Titanium Sintered Fiber Felt for Hot Gas Filtration is a specialized industrial filtering medium designed to withstand the rigors of high-temperature gas streams while effectively capturing particulate matter. This material is fabricated using advanced manufacturing techniques that involve the sintering of titanium fibers into a porous, yet strong and durable felt-like structure.

Titanium, known for its exceptional strength and corrosion resistance, is an ideal material for hot gas filtration applications in industries such as aerospace, chemical processing, power generation, and petroleum refining. The use of titanium ensures that the filter can operate in environments where temperatures may reach several hundred degrees Celsius without compromising its structural integrity or performance.

The manufacturing process for metal titanium sintered fiber felt typically involves the following steps:

- Material Selection. High-quality titanium fibers are chosen as the base material. The purity and particle size of the titanium are critical factors that determine the final properties of the felt.

- Forming. The titanium fibers are laid out in a manner that allows for the creation of a web or mat. This web is then pressed or needled to create a preform, which is the precursor to the final sintered product.

- Sintering. The preform is subjected to high temperatures in a controlled environment. During sintering, the titanium particles fuse together without melting completely, creating a porous structure with interconnected pores that allow for efficient gas flow while trapping solid particles.

- Machining and Finishing. Once sintered, the metal felt may undergo additional machining to achieve specific dimensions or shapes required for the intended application. Surface treatments may also be applied to enhance certain properties, such as oxidation resistance or hydrophobicity.

The resultant Metal Titanium Sintered Fiber Felt possesses several key characteristics that make it suitable for hot gas filtration:

- High Temperature Resistance. Titanium's high melting point ensures that the filter can withstand extreme temperatures without deformation or degradation.

- Corrosion Resistance. Titanium is highly resistant to corrosive substances commonly found in industrial gas streams, such as acids, alkalis, and salts.

- Structural Integrity. The sintered structure provides a combination of strength and flexibility, allowing the filter to handle mechanical stress and vibration without breaking or becoming damaged.

- High Filtration Efficiency. The fibrous nature of the felt combined with its porosity enables efficient capture of even very small particles from the gas stream.

- Long Service Life. The durability of the material means that these filters can maintain performance over extended periods of use, reducing maintenance costs and downtime.

- Cleanability. Depending on the application, the metal felt can often be cleaned by reverse airflow or pulse jet cleaning, restoring its filtration capabilities without the need for replacement.

Applications

The metal titanium sintered fiber felt finds widespread application in:

- High-temperature gas filtration systems

- Incinerators for hazardous waste treatment

- Power generation plants (coal-fired or biomass)

- Metal smelting and refining processes

- Petrochemical processing units

- Aerospace industry for engine exhaust filtration

- Environmental protection technologies, especially for flue gas desulfurization and denitrification

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português