Product Details

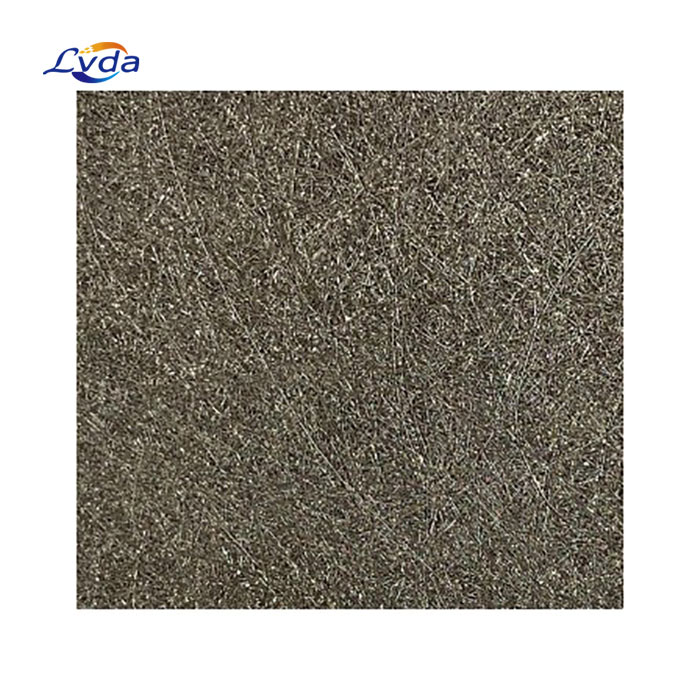

In the realm of filtration technology, titanium fiber felt emerges as a versatile and highly effective material capable of achieving high-precision removal of impurities while maintaining a substantial pollution holding capacity. This unique property positions titanium fiber felt as an indispensable tool in various industrial applications where separating tiny particles or dissolved substances from fluids is paramount. From industrial wastewater treatment to air purification and the purification processes of chemical products, titanium fiber felt plays a pivotal role in enhancing efficiency and ensuring the quality of the end products.

Function Of Titanium Fiber Felt In Deep Filtration

titanium fiber felt serves as a crucial component in deep filtration systems designed to remove impurities with exceptional precision. Its intricate structure allows for the effective capture of even the smallest particles and dissolved substances present in fluids, ensuring that the output meets stringent quality standards. By providing a reliable barrier against contaminants, titanium fiber felt helps industries maintain the purity of their processes and products, safeguarding against potential damage or contamination.

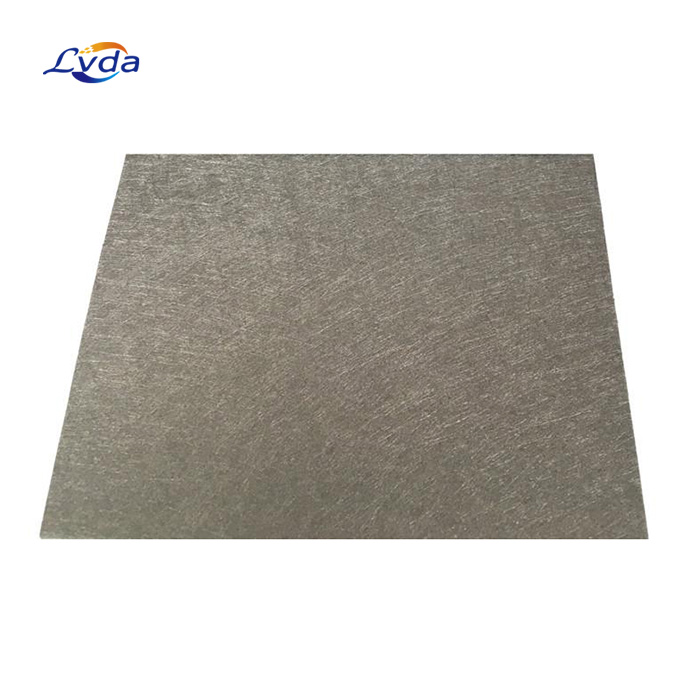

Parameters

Thickness : 0.25mm, 0.4mm, 0.6mm, 0.8mm, 1mm, etc

Color : Light gray

Porosity : 60-70%

Size : Customizable

Features Of Titanium Fiber Felt For Deep Filtration

1. High precision filtration. Titanium fiber felt excels in capturing tiny particles and dissolved substances, thanks to its fine mesh structure that offers unparalleled filtration efficiency.

2. Large pollution holding capacity. Despite its precision, titanium fiber felt can hold a significant amount of pollutants, reducing the frequency of replacements and enhancing cost-effectiveness.

3. Chemical resistance. Titanium fiber felt exhibits excellent resistance to corrosion and chemical reactions, ensuring long-term durability and reliability in harsh industrial environments.

4. Temperature resistance. With the ability to withstand high temperatures, titanium fiber felt remains stable and effective across a wide range of operating conditions.

5. Low maintenance. Due to its robust nature and efficient filtration capabilities, titanium fiber felt requires minimal maintenance, contributing to overall operational efficiency.

Applications Of Titanium Fiber Felt In Various Industries

1. Industrial wastewater treatment. Titanium fiber felt is extensively used in the filtration of industrial wastewater, where it effectively removes contaminants and pollutants, ensuring compliance with environmental regulations.

2. Air purification. In air purification systems, titanium fiber felt helps trap particulate matter and harmful gases, improving air quality in industrial settings and contributing to a healthier work environment.

3. Chemical product purification. Titanium fiber felt plays a crucial role in the purification processes of chemical products, ensuring the removal of impurities and enhancing the quality and purity of the final products.

4. Oil and gas industry. Titanium fiber felt finds applications in the oil and gas industry for filtration processes, where it helps enhance the efficiency of separation techniques and ensures the quality of extracted substances.

In conclusion, titanium fiber felt stands out as a reliable and versatile material for deep filtration applications, offering high-precision filtration, large pollution holding capacity, and resistance to harsh industrial conditions. Its widespread use across industries such as wastewater treatment, air purification, and chemical product purification underscores its importance in enhancing process efficiency and ensuring product quality. By adhering to precautions and best practices in handling and utilizing titanium fiber felt, industries can leverage its benefits to drive innovation and sustainability in their operations.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português