Product Details

Hydrogen fuel cells, a promising clean energy technology, have been gaining significant attention due to their high efficiency and zero-emission properties. The core of these fuel cells is the membrane electrode assembly (MEA), where chemical reactions take place to convert hydrogen into electricity. A crucial component within the MEA is the gas diffusion layer (GDL), which plays an instrumental role in optimizing cell performance. One advanced material used for this purpose is titanium fiber felt, which serves as a hydrogen fuel cell gas diffusion layer, offering improvements in water management and overall cell performance.

Understanding the Gas Diffusion Layer (GDL)

The GDL is sandwiched between the catalyst-coated membrane (CCM) and bipolar plates in a fuel cell stack. Its primary functions include:

1. Distribute Hydrogen and Oxygen. It provides pathways for reactant gases (hydrogen and oxygen) to reach the catalyst sites uniformly.

2. Manage Water Transport. Efficient water management is critical in PEM (Proton Exchange Membrane) fuel cells because the reaction produces water as a byproduct. The GDL must allow for the removal of excess liquid water while retaining enough moisture to keep the membrane hydrated.

3. Electrical Conduction. The GDL also acts as an electrical conductor, transferring electrons from the catalyst layer to the bipolar plate.

4. Mechanical Support. It offers structural support to the fragile CCM, ensuring mechanical stability under operating conditions.

Titanium Fiber Felt: A High-Performance GDL Material

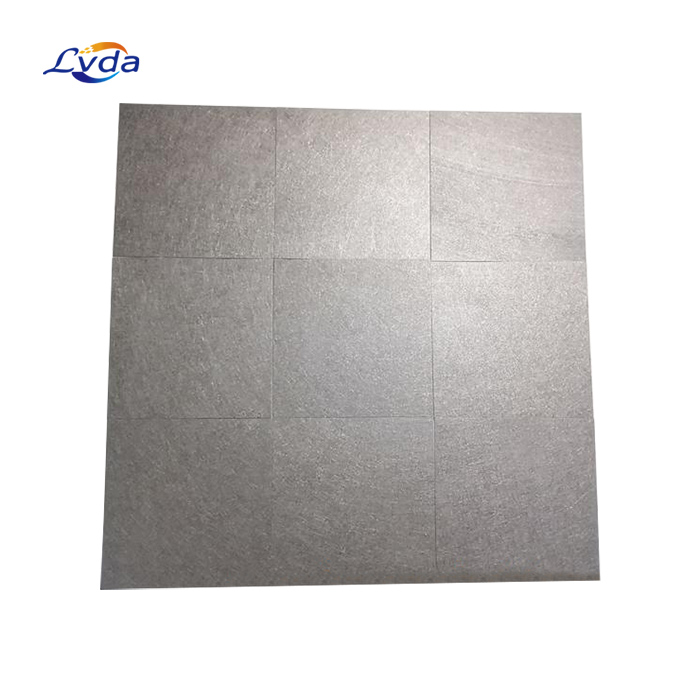

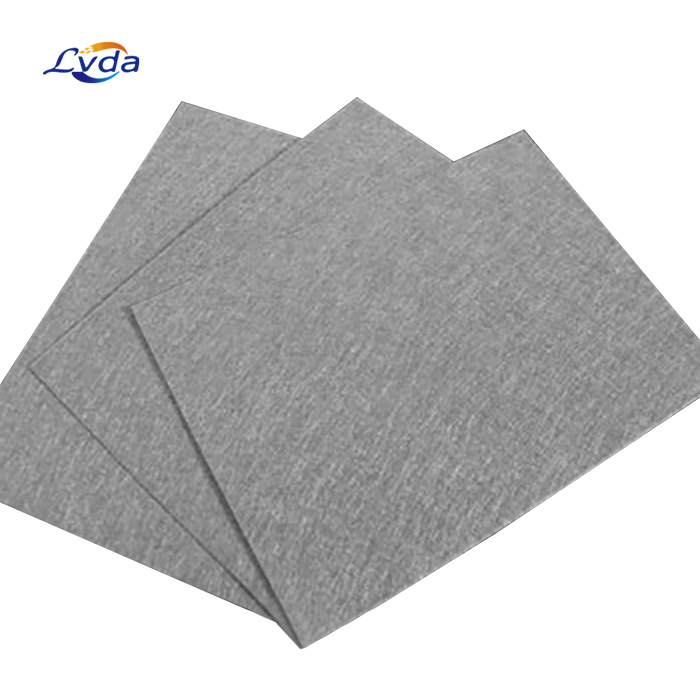

Titanium fiber felt, with its unique properties, stands out as an ideal choice for the GDL in hydrogen fuel cells. This material is composed of interwoven titanium fibers that form a porous, three-dimensional structure. Here are several aspects that highlight its benefits:

1. Excellent Chemical Stability. Titanium exhibits excellent corrosion resistance against acidic environments such as those found in PEM fuel cells where sulfuric acid is present as a proton carrier. This property ensures a long operational life and minimizes degradation over time.

2. Superior Mechanical Strength. The inherent strength and durability of titanium fibers make the felt robust enough to withstand compressive forces during assembly and resist wear and tear during operation. This feature maintains consistent contact between the GDL and other components, thereby enhancing cell performance.

3. Optimal Porosity and Tortuosity. The felt’s porosity can be tailored to facilitate efficient gas diffusion while maintaining appropriate water transport. The tortuous path created by the interconnected fibers enhances capillary action, allowing better control over water distribution within the cell.

4. Low Electrical Resistance. Titanium has low electrical resistivity, enabling it to conduct electrons effectively from the catalyst layer to the bipolar plate. This reduces ohmic losses and contributes to higher power output and efficiency.

5. Enhanced Thermal Conductivity. Compared to conventional carbon-based GDLs, titanium fiber felt offers improved thermal conductivity. This attribute helps dissipate heat generated during the electrochemical reactions more efficiently, preventing hot spots and prolonging the lifespan of the fuel cell.

6. Environmental Compatibility. Being metal-based, titanium does not release harmful particulates or chemicals when exposed to high temperatures or during degradation, making it environmentally friendly and safe for use in automotive and stationary applications.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português