Product Details

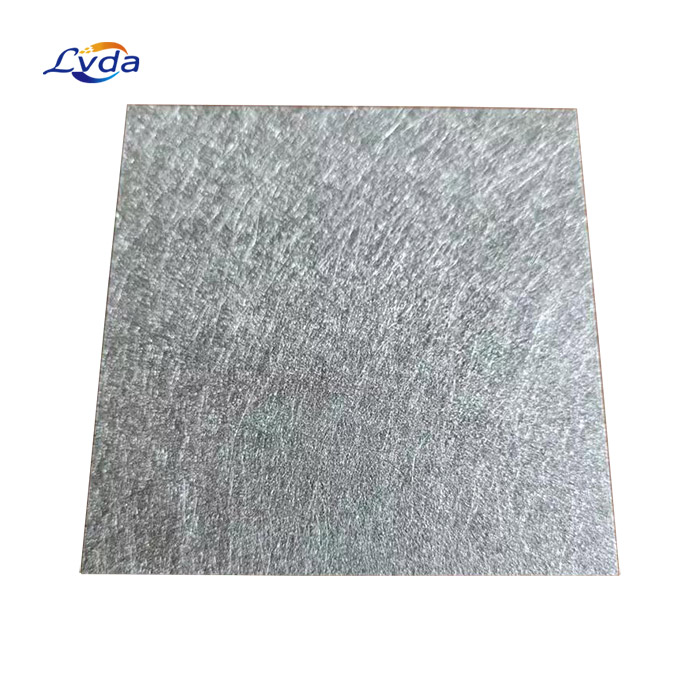

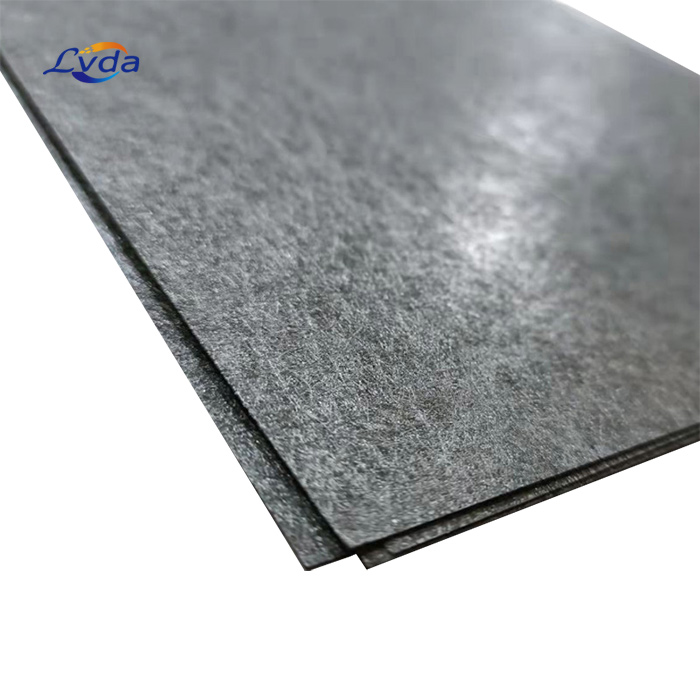

One crucial component of hydrogen suction machines is the reliable quality titanium felt. This innovative material plays a vital role in the efficient and safe operation of these devices. Titanium felt is a highly porous material made from pure titanium fibers. These fibers are sintered together to form a three-dimensional structure with interconnected pores. This unique structure gives titanium felt its remarkable characteristics, making it ideal for demanding applications like hydrogen extraction.

Properties of Titanium Felt

1. High corrosion resistance. Titanium is known for its exceptional corrosion resistance, making it an ideal choice for environments where exposure to harsh chemicals or gases such as hydrogen is common. The titanium felt used in hydrogen suction machines can withstand corrosive substances without degrading, ensuring long-term reliability.

2. Excellent thermal stability. Another significant advantage of titanium felt is its high thermal stability. It can withstand extreme temperatures without losing its structural integrity, which is crucial for applications involving hydrogen suction where temperature fluctuations are expected.

3. Good conductivity. Titanium felt exhibits good electrical conductivity, facilitating efficient operation within hydrogen suction machines. This property enables enhanced performance and ensures that the machine operates effectively in extracting hydrogen gas.

4. High strength-to-weight ratio. Despite its lightweight nature, titanium felt is incredibly strong. This property is advantageous for hydrogen suction machines as it provides structural robustness without adding unnecessary weight to the system.

Manufacturing Process and Quality Control

Manufacturing reliable quality titanium felt involves stringent quality control measures to ensure consistency and performance. The process typically includes:

1. Material selection. High-grade titanium fibers are selected for their purity and specific properties required for hydrogen suction applications.

2. Felt formation. The titanium fiber undergoes processing to create a porous felt structure that facilitates efficient gas diffusion and filtration.

3. Quality testing. Each batch of titanium felt is subjected to rigorous quality testing to verify its corrosion resistance, thermal stability, conductivity, and strength.

4. Customization. Manufacturers offer customization options to meet the unique requirements of different hydrogen suction machines, ensuring a perfect fit and optimal performance.

Advantages of Using Reliable Quality Titanium Felt

1. Improved efficiency. The use of high-quality titanium felt in hydrogen suction machines enhances their efficiency by ensuring optimal gas extraction and filtration. This leads to improved operational performance and productivity.

2. Cost-effectiveness. While titanium felt may have a higher initial cost compared to other materials, its durability and longevity make it a cost-effective choice in the long run. The reduced need for frequent replacements or maintenance translates to savings over time.

3. Safety and reliability. Reliable quality titanium felt provides an added layer of safety in hydrogen suction machines by withstanding corrosive environments and high temperatures. Its robust construction minimizes the risk of malfunctions or failures, ensuring a reliable operation.

4. Environmental sustainability. Titanium is a recyclable material, making it an environmentally friendly choice for hydrogen suction machines. By using titanium felt, manufacturers contribute to sustainable practices and reduce the environmental impact of their operations.

Applications of Titanium Felt in Hydrogen Suction Machines

1. Optimal gas diffusion. The structure of titanium felt allows for uniform gas diffusion, enabling effective suction of hydrogen gas within the machine. This feature ensures that the gas is extracted efficiently, contributing to the overall performance of the system.

2. Enhanced filtration. Titanium felt can serve as an excellent filtration medium in hydrogen suction machines, effectively trapping impurities and contaminants present in the gas stream. This filtration capability helps maintain the purity of the extracted hydrogen, making it suitable for various industrial processes.

3. Longevity and durability. Due to its robust nature, titanium felt offers longevity and durability in hydrogen suction machines. It can withstand continuous use and exposure to demanding conditions without deteriorating, ensuring reliable performance over an extended period.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português