Product Details

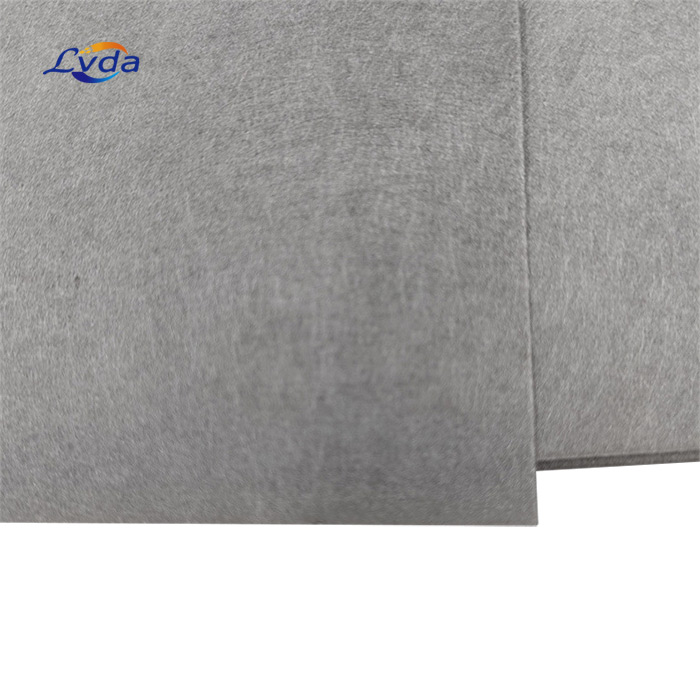

The 50%-80% porosity pure titanium electrode porous fiber felts for PEM fuel cells are a critical component in the design and operation of proton exchange membrane (PEM) fuel cells, which are a type of electrochemical cell that converts chemical energy directly into electricity through a hydrogen-air reaction. These porous fiber felts serve as both the anode and cathode current collectors, providing electrical conductivity while also allowing gas diffusion and water management within the cell.

The porosity range specified is indicative of the open space or void fraction within the felt structure, which plays a significant role in determining its performance in a fuel cell. A higher porosity allows greater gas diffusion and may enhance performance by providing more surface area for the reaction; however, it can also increase pressure drop across the felt, potentially leading to increased pumping power requirements. Conversely, lower porosities offer better structural integrity and possibly lower pressure drops but at the expense of reduced gas diffusion.

Titanium fiber felts are chosen for their exceptional properties such as high temperature resistance, good chemical stability, excellent mechanical strength, and low electrical resistivity. The material's biocompatibility makes it especially suitable for use in medical devices and implants. In addition, titanium does not react with hydrogen, which is essential for fuel cell applications.

Manufacturing these felts involves complex processes including fiber production, nonwoven fabric formation, and subsequent densification and sintering to achieve the desired porosity and mechanical properties. The fibers used can be either continuous or discontinuous, each offering different benefits. Continuous fibers provide better thermal and electrical conductivity, whereas discontinuous fibers are easier to process and may result in a more uniform porosity distribution.

The application of these felts in PEM fuel cells is crucial for maintaining proper gas and water management. At the anode, hydrogen gas diffuses through the felt matrix where it reacts with protons and oxygen ions to produce water, electrons, and heat. The water produced must then diffuse back through the felt to the cathode side. Similarly, at the cathode, oxygen molecules diffuse through the felt and react with the protons and electrons to form water.

The felt's ability to handle this water management is key to preventing flooding, which can disrupt the cell's performance. The felt's porosity and thickness play a role in balancing the diffusion rates of the reactants and products with minimizing the pressure drop across the cell.

The application of these titanium felts in PEM fuel cells is not limited to a specific role. They can be used as gas diffusion layers (GDLs) or as components of the electrode assembly. As GDLs, they facilitate the uniform distribution of reactant gases over the catalyst layer, ensuring efficient gas utilization. As part of the electrode assembly, they contribute to the structural integrity of the electrode and provide a stable support for the catalyst material.

In addition to the use in PEM fuel cells, these titanium fiber felts have potential applications in other technologies requiring high temperature and corrosion resistance, such as electrolyzers for hydrogen production, aerospace components, and various industrial processes.

Specifications:

- Material : Titanium fiber

- Porosity : 50%-80%

- Thickness : 0.25mm/0.4mm/0.6mm/0.8mm/1.0mm/etc

- Size : Customized

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português