Product Details

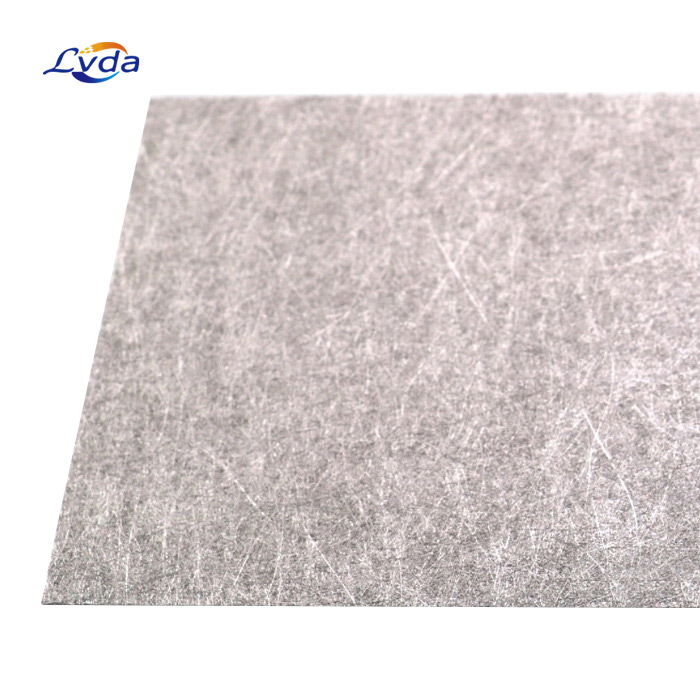

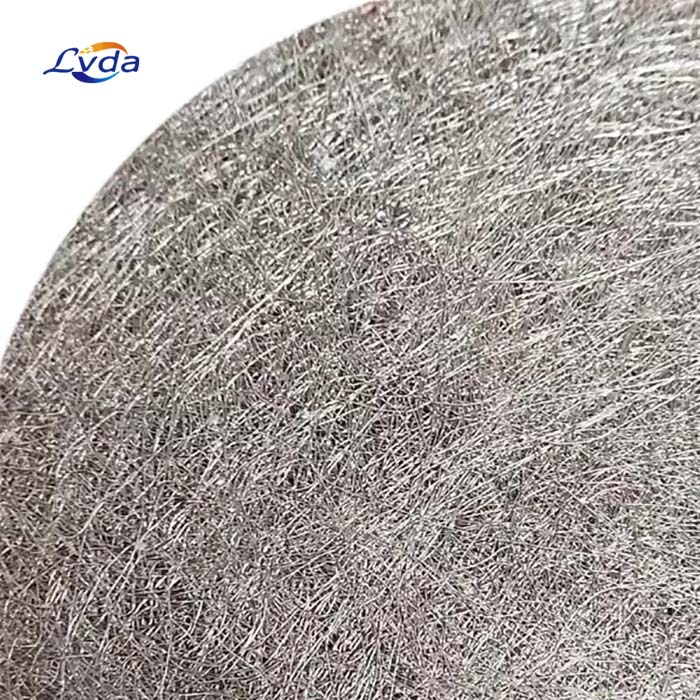

Porous Titanium Felt, a highly innovative and specialized material, has gained significant traction in the chemical fiber industry due to its unique properties and exceptional performance in the filtration of high-viscosity polymers. This advanced material is engineered by interweaving titanium fibers into a felt-like structure, which creates a porous matrix with an intricate network of interconnected pores that facilitate efficient filtration while maintaining structural integrity under demanding conditions.

In the context of high-viscosity polymer filtration, porous titanium felt plays a critical role in removing impurities, such as gels, particulates, and undissolved catalysts, from viscous polymer melts. Its porous structure provides a large surface area, enabling effective interception and entrapment of contaminants through mechanisms like depth filtration, where particles are progressively captured throughout the entire thickness of the felt. Moreover, the even pore distribution ensures uniform flow and minimizes pressure drops, thus preventing channeling and promoting consistent filtration quality.

Parameters

Porosity : 60% - 85%

Thickness : 0.25mm - 3mm

Shape : Round, square or rectangle

Material : Titanium

Size : As the customer required

Advantages of Porous Titanium Felt

The use of Porous Titanium Felt in the chemical fiber industry offers several advantages over traditional filtration materials:

a. Superior filtration efficiency - The high porosity and uniform pore structure of Porous Titanium Felt ensure efficient filtration of high-viscosity polymers, resulting in improved product quality and reduced waste.

b. Excellent chemical stability - The excellent resistance of titanium to chemicals makes Porous Titanium Felt suitable for filtration applications in harsh chemical environments, preventing corrosion and ensuring long-term durability.

c. High mechanical strength - Porous Titanium Felt can withstand high mechanical forces, reducing the risk of filtration system failures and ensuring uninterrupted production.

d. Wide temperature range - The high thermal stability of Porous Titanium Felt allows it to be used in filtration processes involving high temperatures, which is common in the chemical fiber industry for polymerization and processing steps.

e. Easy cleaning and maintenance - The open structure of Porous Titanium Felt allows for easy removal of filter cakes, which can be cleaned manually or automated, reducing downtime and maintenance costs.

f. Long service life - The combination of high mechanical strength and resistance to chemical degradation results in a longer service life for Porous Titanium Felt compared to traditional filtration materials, such as filter papers or metals, which can corrode or wear out quickly.

g. Customizability - Porous Titanium Felt can be manufactured with varying porosities, pore sizes, and thicknesses to suit specific filtration requirements in the chemical fiber industry, offering tailor-made solutions for different manufacturing processes.

Application in Chemical Fiber Industry

Polymer filtration is a crucial step in the production of various chemical fibers, including polyester, nylon, and polypropylene. During melt spinning, where polymers are melted, filtered, and extruded through spinnerets to form fibers, any impurities could lead to defects in the final product. Porous titanium felt serves as a reliable pre-filter or fine filter, ensuring the purity and consistency of the polymer melt before it is transformed into fibers.

Moreover, its effectiveness extends to post-spinning treatments, such as washing and drying stages, where further filtration may be required to remove residual impurities or fines. In this way, porous titanium felt significantly contributes to enhancing the overall quality and efficiency of the chemical fiber manufacturing process.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português