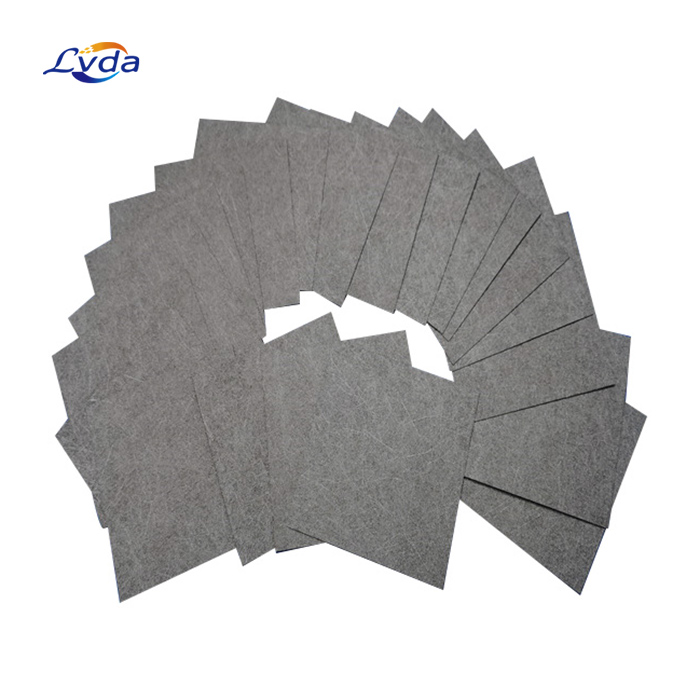

Product Details

In the realm of industrial electrolysis, maintaining the purity of electrolytes is paramount to ensuring efficient and reliable operations. The introduction of heat-resistant titanium sintered fiber felt has refined the filtration process within electrolyzers. This innovative material not only exhibits exceptional heat resistance but also boasts a fine porous structure that facilitates effective filtration.

Parameters:

- Place of Origin : Henan, China

- Condition : New

- Material : Titanium

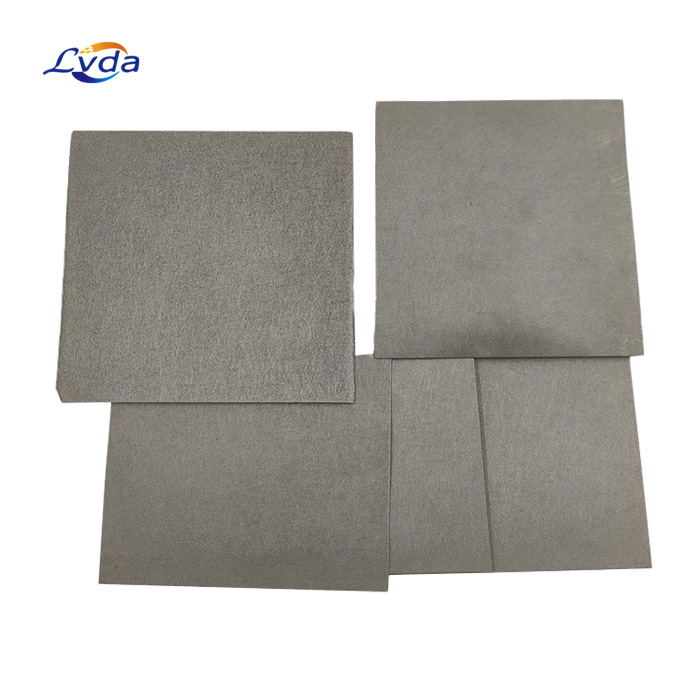

- Thickness : 0.2mm - 2mm

- Filtration Efficiency : 99%

- Size : Customized

- Shape : Customized

Titanium sintered fiber felt is composed of titanium fibers that are sintered together to form a coherent structure. The sintering process involves heating the fibers to a high temperature, causing them to partially melt and fuse together. This results in a material with a uniform pore size distribution and enhanced mechanical strength.

One of the key properties of titanium sintered fiber felt is its excellent heat resistance. This material can withstand high temperatures without degrading, making it ideal for use in environments where elevated temperatures are prevalent. Additionally, the felt's porous structure allows for efficient fluid flow while still retaining particles and impurities.

The filtration mechanism of titanium sintered fiber felt relies on its intricate pore structure. As electrolyte flows through the felt, particles and impurities are intercepted by the pores, preventing them from passing through to the other side. This process ensures that the electrolyte remains pure, which is crucial for optimal electrolysis performance.

Titanium sintered fiber felt is particularly well-suited for use in electrolyzers due to its heat resistance and filtration capabilities. In these devices, the electrolyte is subjected to high temperatures and electrical currents, which can lead to the formation of impurities and particulates. By incorporating titanium sintered fiber felt into the electrolyzer design, these contaminants can be effectively removed, resulting in a cleaner and more efficient electrolysis process.

Compared to traditional filtration materials, titanium sintered fiber felt offers several advantages. Its heat resistance allows it to operate in harsh environments without compromising performance. Additionally, its fine porous structure provides superior filtration efficiency, ensuring that even the smallest particles are captured. Furthermore, the material's durability and resistance to chemical corrosion make it a reliable and long-lasting solution for electrolyzer filtration.

Installing titanium sintered fiber felt in an electrolyzer is a straightforward process. The felt is typically cut to size and then placed within the electrolyzer, where it can be easily accessed for cleaning and maintenance. Regular cleaning of the felt is essential to maintain its filtration efficiency and prevent clogging.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português