Product Details

The development and widespread adoption of new energy sources, particularly hydrogen fuel cells, have become a pivotal element in addressing environmental concerns and promoting sustainable energy solutions. Hydrogen fuel cells, which generate electricity through the electrochemical conversion of hydrogen gas, are recognized for their high efficiency and zero-emission operation. However, to ensure optimal performance and longevity of these cells, advanced materials such as long service life titanium felt are indispensable.

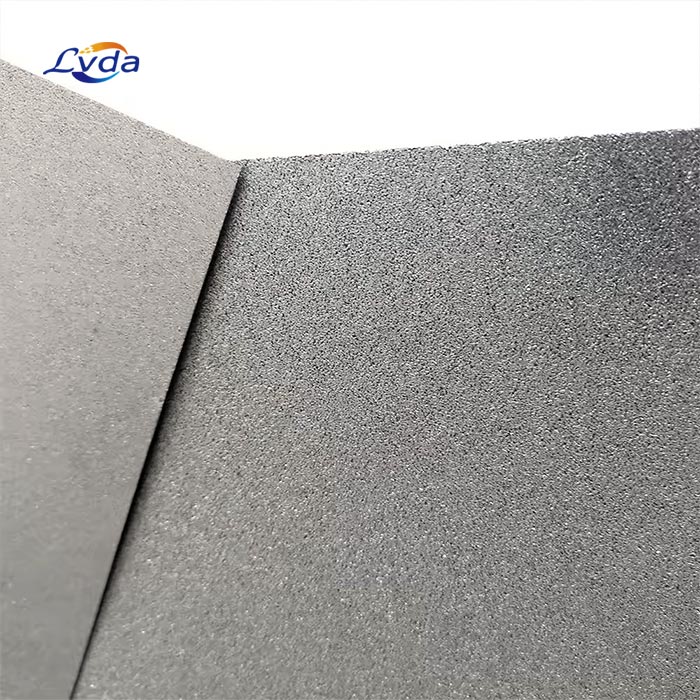

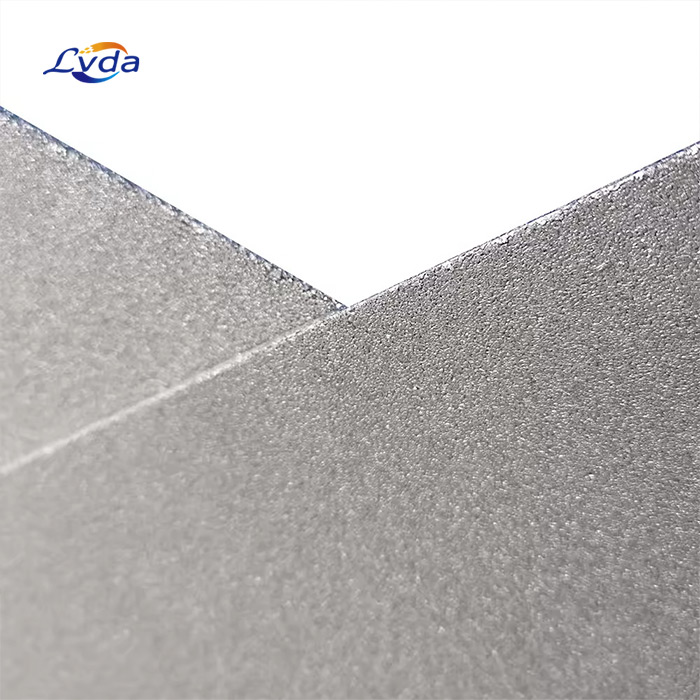

Titanium felt is a unique material composed of fine titanium fibers that are interwoven or bonded together to form a flexible, yet robust fabric. The use of titanium as the primary material is due to its exceptional strength-to-weight ratio, corrosion resistance, and thermal stability. These properties make titanium felt an ideal candidate for various industrial applications, including filtration, insulation, and catalyst support. In the context of hydrogen fuel cells, titanium felt serves as a gas diffusion layer (GDL), which plays a critical role in facilitating the transfer of gases (hydrogen and oxygen) between the cell's anode and cathode.

The long service life aspect of titanium felt is achieved through meticulous engineering and material selection. Firstly, the fibers used in the production of this felt are subjected to rigorous quality control to ensure uniformity and consistency in size and shape. This uniformity enhances the mechanical stability of the felt, preventing premature wear and tear during the cell's operation. Secondly, the interweaving process is carefully controlled to create a dense but porous structure that allows for efficient gas flow while minimizing the risk of clogging over time. This design feature contributes significantly to the longevity of the titanium felt as it reduces the likelihood of performance degradation caused by blockages or restricted gas flow.

In addition to its structural integrity, long service life titanium felt also exhibits excellent chemical stability. The material is highly resistant to oxidation and reduction reactions, making it suitable for use in the harsh environments encountered within hydrogen fuel cells. This resistance ensures that the titanium felt maintains its physical and chemical properties throughout the cell's lifespan, thereby preserving its functionality and contributing to the overall efficiency of the fuel cell system.

Another notable feature of long service life titanium felt is its thermal conductivity. While not as high as some other materials, the thermal conductivity of titanium felt is sufficient to dissipate heat generated during the cell's operation. This property is essential in maintaining the operating temperature within safe limits and ensuring the longevity of the cell components. By effectively managing heat, the titanium felt helps to prevent hot spots and thermal stress, which can lead to material degradation and reduced performance over time.

Parameters

Material : Ti

Porosity : 50-70%

Size : 200×200, 205×205, 300×300, 305×305mm, etc

Thickness : 0.1mm - 2mm

Applications

Titanium felt finds applications in various types of hydrogen fuel cells, including polymer electrolyte membrane (PEM) fuel cells and solid oxide fuel cells (SOFCs). In PEM fuel cells, the titanium felt serves as the electrolyte membrane, enabling the efficient transfer of protons while preventing the mixing of fuel and oxygen gases. This results in improved fuel cell performance and durability. In SOFCs, titanium felt can be used as a component in the anode, cathode, or interconnect, providing high thermal stability and excellent chemical resistance.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português