Product Details

Porous sintered titanium fiber felt has emerged as a crucial material in the field of PEM (Proton Exchange Membrane) water electrolysis for hydrogen production. This innovative material plays a pivotal role in enabling efficient and sustainable hydrogen generation, offering significant advancements in the quest for clean energy solutions.

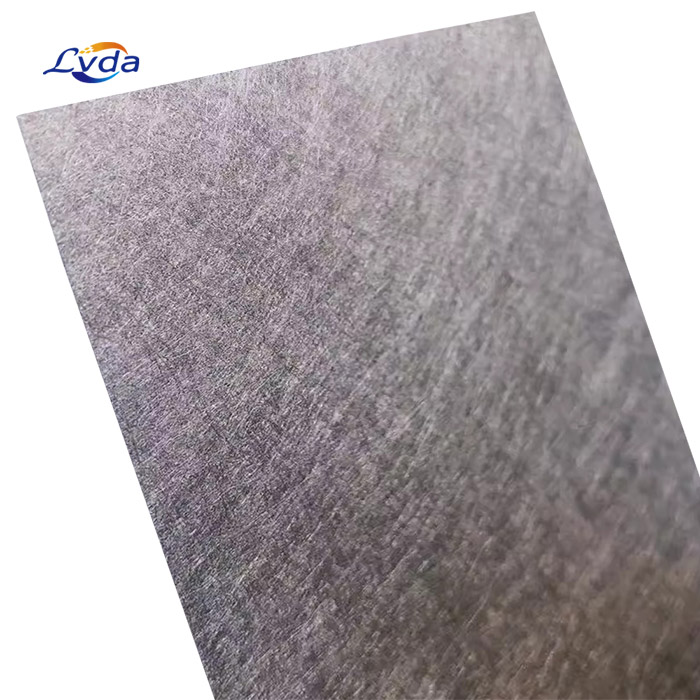

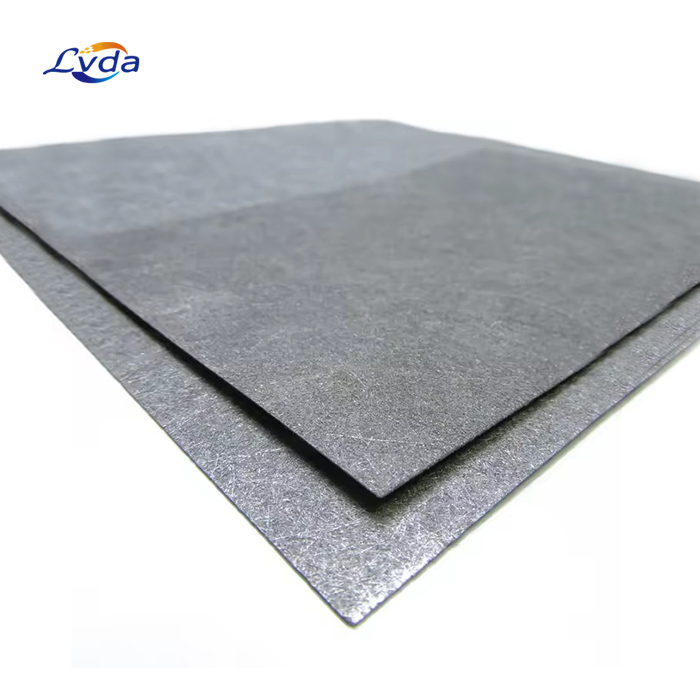

Porous sintered titanium fiber felt is characterized by its high porosity, large specific surface area, excellent corrosion resistance, and remarkable durability. These properties make it an ideal candidate for serving as an electrode substrate in PEM water electrolysis systems. The unique structure of the material facilitates the efficient transport of reactants and products, thus enhancing the performance and overall efficiency of the electrolysis process.

In PEM water electrolysis, the porous sintered titanium fiber felt serves as a support structure for the catalyst layer, providing a stable and conductive foundation for facilitating the electrochemical reactions involved in hydrogen evolution and oxygen evolution. The high surface area of the material allows for efficient catalyst loading, promoting enhanced catalytic activity and improved mass transport within the electrolysis cell.

Parameters

Material : Titanium

Size : Customized

Shape : Customized

Layer : Multilayer

Technique : Sintering

Place of Origin : China

Condition : New

***The product can be customized.

Benefits of Porous Sintered Titanium Fiber Felt in PEM Water Electrolysis

1. Enhanced Catalytic Activity. The porous structure of the sintered titanium fiber felt provides a large active surface area, which promotes better contact between the catalyst and electrolyte. This enhanced catalytic activity facilitates faster reaction rates, resulting in improved hydrogen generation efficiency.

2. Improved Gas Diffusion. The interconnected pores in the fiber felt enable rapid gas diffusion within the electrolyzer, ensuring optimal utilization of the electrode surface area. This feature helps mitigate mass transfer limitations, leading to more effective hydrogen production.

3. Excellent Corrosion Resistance. Titanium is known for its exceptional corrosion resistance, making porous sintered titanium fiber felt highly durable in harsh electrolysis environments. This resistance to corrosion ensures the longevity and reliability of PEM water electrolysis systems utilizing this material.

4. Uniform Current Distribution. The uniform distribution of current across the electrode surface is critical for achieving efficient electrolysis. The porous structure of the titanium fiber felt helps in maintaining a consistent current density, minimizing hotspots and improving overall system stability.

5. Scalability and Versatility. porous sintered titanium fiber felt can be easily customized and fabricated into various shapes and sizes, making it adaptable to different electrolyzer designs and configurations. Its scalability and versatility make it a versatile material for PEM water electrolysis applications.

Applications of Porous Sintered Titanium Fiber Felt in PEM Water Electrolysis Systems

The utilization of porous sintered titanium fiber felt in PEM water electrolysis systems has opened up new possibilities for advancing hydrogen production technologies. Some key applications include:

1. High-Efficiency Electrolyzers. By integrating porous sintered titanium fiber felt as the electrode material, manufacturers can enhance the efficiency and performance of PEM water electrolysis systems, leading to increased hydrogen yield and lower energy consumption.

2. Renewable Energy Storage. PEM water electrolysis coupled with porous sintered titanium fiber felt offers a sustainable solution for storing excess renewable energy in the form of hydrogen. This stored hydrogen can be later used for power generation or transportation fuel.

3. Industrial Hydrogen Production. Industries seeking to transition to greener hydrogen production methods can benefit from the use of porous sintered titanium fiber felt in large-scale PEM electrolyzers. The material's durability and efficiency make it well-suited for industrial applications.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português