Product Details

High porosity hydrogen production industry sintered titanium felt is a cutting-edge technology that involves the use of a sintered titanium felt material to produce hydrogen. The sintered titanium felt material is characterized by its high porosity, which enables it to absorb and store large amounts of hydrogen gas. The high porosity of the material is achieved through a unique manufacturing process that involves the consolidation of titanium powder into a felt-like structure using high temperature and pressure.

The hydrogen production process using sintered titanium felt involves the electrochemical splitting of water molecules into hydrogen and oxygen. The sintered titanium felt acts as an electrode in this process, facilitating the absorption and desorption of hydrogen gas. The high porosity of the material enables it to absorb large amounts of hydrogen gas, which can be stored and used as needed.

Parameters

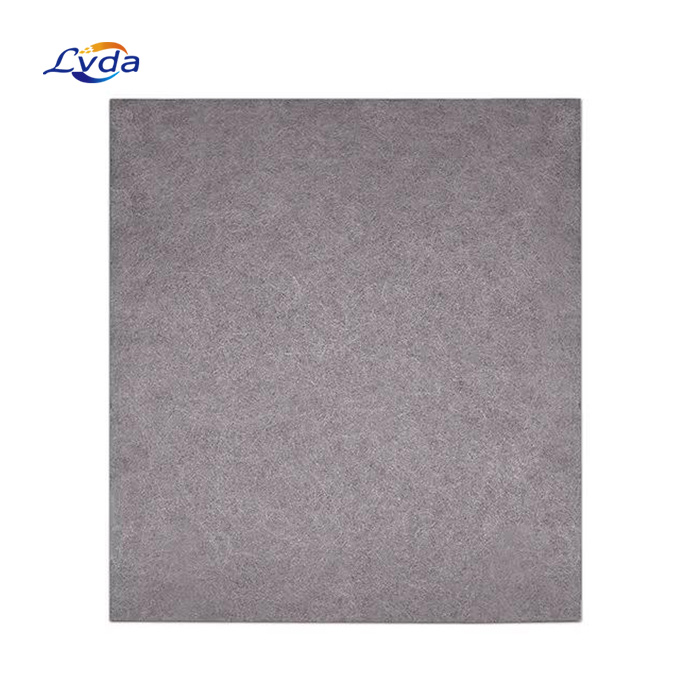

Material : Titanium

Shape : Square, rectangle or other

Size : 10x10cm, 20x20cm, 30x30cm, 40x40cm or customized

Thickness : 0.25mm-2mm

Porosity : 60%-70%

Features and Benefits

The high porosity hydrogen production industry sintered titanium felt offers several features and benefits that make it an attractive option for clean energy applications. Some of the key features and benefits are:

1. High Energy Density. Hydrogen has one of the highest energy densities of any fuel, making it an ideal candidate for clean energy applications. The high porosity hydrogen production industry sintered titanium felt enables the efficient production of hydrogen, making it a viable option for various applications.

2. Zero Emissions. Hydrogen fuel cells produce only water as a byproduct, making them an environmentally friendly option for clean energy. The high porosity hydrogen production industry sintered titanium felt enables the safe and efficient production and storage of hydrogen, making it a viable option for zero-emission vehicles and other applications.

3. High Safety. Hydrogen is highly reactive and can pose safety risks if not handled properly. The high porosity hydrogen production industry sintered titanium felt offers a safe and secure method of storing hydrogen due to its high porosity and unique manufacturing process.

4. Cost-Effective. The high porosity hydrogen production industry sintered titanium felt offers a cost-effective solution for clean energy applications. The use of sintered titanium felt as an electrode in the hydrogen production process reduces the cost of the electrochemical splitting of water molecules compared to traditional methods.

5. Versatile. The high porosity hydrogen production industry sintered titanium felt can be used in various applications, including zero-emission vehicles, portable power sources, and stationary power generation. Its versatility makes it an attractive option for clean energy applications.

Applications

Sintered titanium felt has several applications in hydrogen production, including:

1. Catalysis. The high surface area and porosity of sintered titanium felt make it an excellent support for catalysts used in hydrogen production processes. For example, it can be impregnated with nickel or other metals to create a catalyst for SMR or partial oxidation of hydrocarbons.

2. Membrane Reactor. The porous structure of sintered titanium felt can be used to create a membrane reactor, where the felt acts as a separator between the reactants and products. This allows for continuous removal of hydrogen from the reaction mixture, increasing the overall efficiency of the process.

3. Electrolysis. In electrolytic hydrogen production, sintered titanium felt can be used as a cathode material, providing a large surface area for the reduction of water molecules to produce hydrogen gas.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português