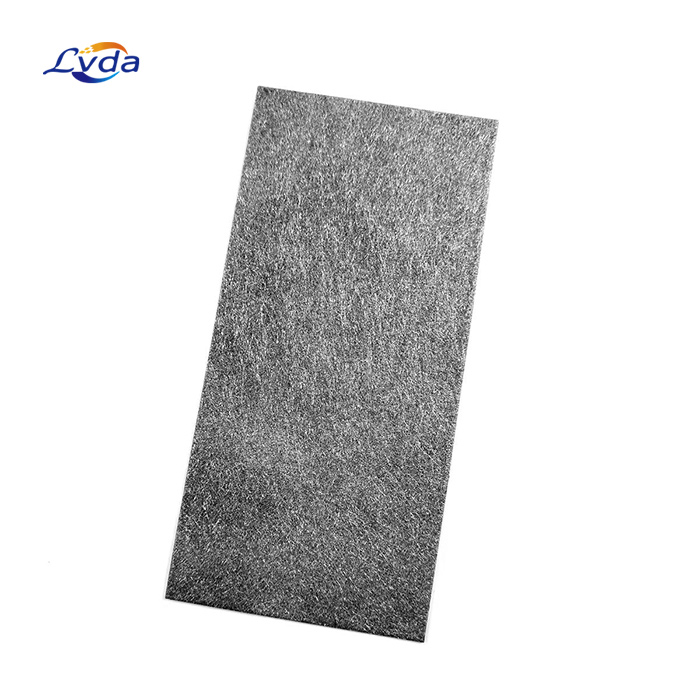

Product Details

In the realm of material science and engineering, the quest for innovative solutions to enhance efficiency and effectiveness is unceasing. Among the myriad materials utilized in various industrial applications, titanium stands out as a versatile and reliable choice owing to its exceptional properties. Sintered titanium fiber felt, with a porosity range of 50%-80%, represents an advanced form of this material that has found particular utility in electrolytic cells.

Parameters

Size : 500x1000mm, 600x1200mm, 1000x1000mm, 1200x1200mm, etc

Porosity : 50%-80%

Thickness : 0.2mm~2mm

Filtration precision : 3-100 micron

Shape : Square, round, rectangle, etc

Utilization in Electrolytic Cells

Electrolytic cells are fundamental components in diverse industries such as chemical processing, metal extraction, and energy storage. These cells rely on the principles of electrolysis, where an electric current is passed through an electrolyte to facilitate chemical reactions. Sintered titanium fiber felt serves as a key element within these cells due to its unique characteristics and performance capabilities.

Porosity: A Critical Parameter

The porosity of sintered titanium fiber felt, ranging from 50% to 80%, plays a pivotal role in determining its suitability for electrolytic cell applications. Porosity refers to the volume percentage of void spaces within the material, which influences crucial factors like fluid flow, gas diffusion, and surface area available for reactions. In the context of electrolytic cells, optimal porosity levels are essential for promoting efficient mass transfer and ensuring uniform distribution of electrolytes across the electrode surface.

Enhanced Mass Transfer and Electrolyte Distribution

The interconnected network of pores in sintered titanium fiber felt enables enhanced mass transfer within the electrolytic cell. By facilitating the movement of ions and molecules through the material structure, the high porosity fosters rapid and efficient electrochemical reactions. Moreover, the controlled porosity range of 50%-80% ensures adequate electrolyte distribution, preventing local concentration gradients that could impede cell performance.

Surface Area and Reactivity

Another significant advantage of sintered titanium fiber felt with 50%-80% porosity lies in its increased surface area, which amplifies the active sites available for electrochemical reactions. The intricate fibrous structure of the material, coupled with the optimal porosity range, maximizes the contact area between the electrolyte and electrode surface. This heightened reactivity enhances the overall efficiency and productivity of electrolytic processes conducted within the cell.

Durability and Corrosion Resistance

Titanium, renowned for its exceptional durability and corrosion resistance, serves as the foundational material for sintered fiber felt used in electrolytic cells. The sintering process further strengthens the material, imparting robustness and stability required for prolonged operational lifespan. The corrosion-resistant nature of titanium ensures longevity and reliability in challenging industrial environments, making it an ideal choice for electrolytic cell applications.

Temperature and Chemical Compatibility

Sintered titanium fiber felt exhibits excellent temperature resistance and chemical compatibility, crucial attributes for sustained performance in electrolytic cells. Operating conditions within these cells often involve elevated temperatures and aggressive chemical environments. The inherent thermal stability and chemical inertness of titanium enable the material to withstand harsh conditions without compromising its structural integrity or functional properties.

Applications Across Industries

The versatility of sintered titanium fiber felt with 50%-80% porosity extends beyond electrolytic cells to encompass a wide range of industrial applications. From electroplating and water treatment to hydrogen production and electrowinning, this advanced material finds utility in diverse sectors where precise control over electrochemical processes is paramount. Its adaptability and reliability make it a preferred choice for engineers and researchers seeking innovative solutions to complex challenges.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português