Product Details

The petrochemical industry is a critical component of the global economy, as it produces a wide range of products, from fuels and lubricants to plastics and synthetic materials. Filtration is an essential process in the petrochemical industry, as it ensures the purity and quality of the products while minimizing waste and reducing the risk of equipment damage. One of the advanced filtration materials used in the petrochemical industry is high-pressure resistance sintered titanium felt. So, what is the high pressure resistance sintered titanium felt?

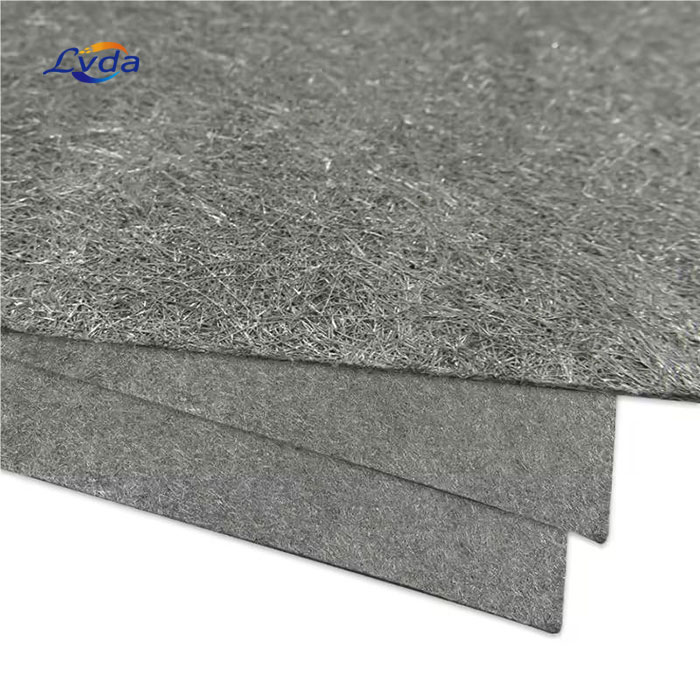

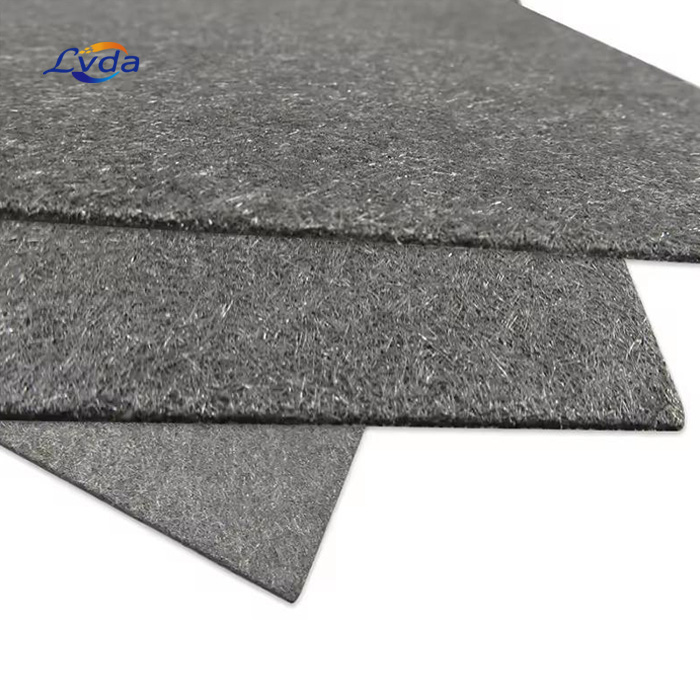

Sintered titanium felt is a type of filter media made from titanium fibers that have been compressed and heated to create a porous, yet strong and durable structure. The high-pressure resistance of this material is achieved through a unique manufacturing process that involves the use of high-pressure dies and advanced sintering techniques. The result is a filtration material that can withstand extremely high pressures, making it ideal for use in the petrochemical industry.

Parameters

Material : Titanium

Porosity : 60-70%

Thickness : 0.2-5mm

Size : Customized

Condition : New

Place of Origin : Xinxiang, Henan, China

Importance of High Pressure Resistance

In the petrochemical industry, components and materials must often withstand high pressures, which can lead to failure if the material is not sufficiently robust. Filtration systems are particularly vulnerable to pressure-induced failures, as they are responsible for maintaining process integrity by removing contaminants. The use of high pressure resistance sintered titanium felt ensures that filtration systems can function effectively and reliably in pressurized environments, leading to increased uptime, reduced risk of contamination, and improved process efficiency.

Benefits of High Pressure Resistance Sintered Titanium Felt

The use of high-pressure resistance sintered titanium felt in the petrochemical industry offers several benefits, including:

1. Improved filtration efficiency. The high porosity and uniform pore size of the material result in improved filtration efficiency, removing even sub-micron particles from liquids and gases.

2. Reduced waste. The high filtration efficiency of the material reduces waste and minimizes the need for disposal, resulting in cost savings and a reduced environmental impact.

3. Increased equipment lifespan. The use of high-pressure resistance sintered titanium felt reduces the risk of equipment damage, resulting in increased equipment lifespan and reduced maintenance costs.

4. Reduced energy consumption. The low pressure drop of the material leads to reduced energy consumption during the filtration process, resulting in cost savings and a reduced environmental impact.

Applications of High Pressure Resistance Sintered Titanium Felt

High-pressure resistance sintered titanium felt has a wide range of applications in the petrochemical industry, including:

1. Oil and gas filtration. The material is used to filter liquids and gases in oil and gas production, ensuring the purity of the products and reducing the risk of equipment damage.

2. Petrochemical processing. The material is used in the filtration of chemicals and other petrochemical products during processing, ensuring the quality of the products and reducing waste.

3. Refining. The material is used in the refining process to filter impurities from crude oil, resulting in higher quality refined products.

4. Pipeline transportation. The material is used to filter liquids and gases during pipeline transportation, reducing the risk of equipment damage and ensuring the purity of the products.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português