Product Details

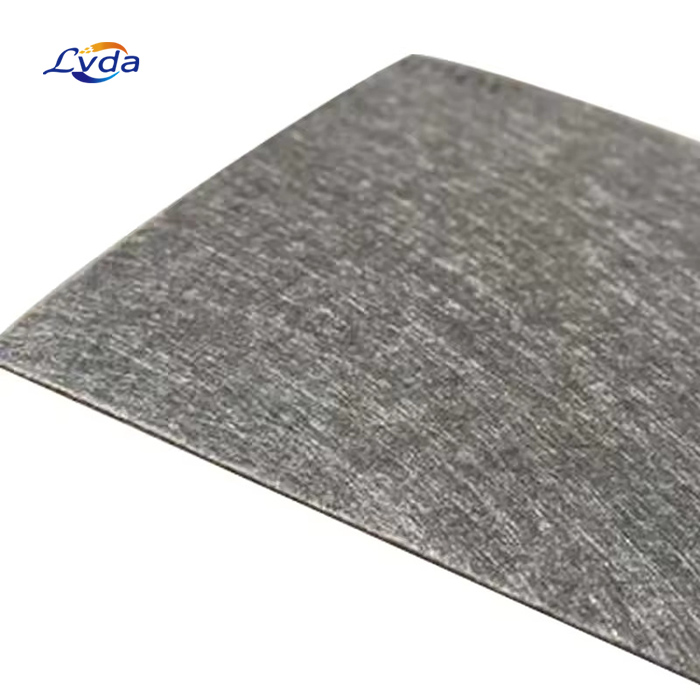

High permeability sintered titanium felt is an advanced filtration material that has been increasingly utilized in various industries due to its exceptional properties and performance. This innovative filtration material offers superior efficiency, durability, and versatility, making it an ideal choice for filter elements in a wide range of applications.

Sintered titanium fiber felt is a unique material that is manufactured through a specialized process involving the sintering of titanium fibers. The result is a highly porous structure with interconnected pore channels, providing an extensive filtration surface area and enabling high permeability. This innovative manufacturing technique ensures the material retains its structural integrity, even under extreme operating conditions, making it an ideal choice for demanding filtration applications.

The versatility of high permeability sintered titanium fiber felt is further demonstrated by its adaptability to various filtration configurations and applications. It can be tailored to specific filtration requirements, such as particle size retention, flow rate, and operating pressure, making it suitable for a wide range of liquid and gas filtration applications. Whether employed as a standalone filter element or as part of a composite filtration system, the material delivers reliable and efficient performance across diverse industries and applications.

Parameters

Material : Titanium

Ti Content : 99.9%

Porosity : 50%-70%

Thickness : 0.2mm-5mm

Size : Customized

Shape : Round, square, rectangle

Place of Origin : Xinxiang, Henan, China

Features

1. High permeability. The high permeability of sintered titanium felt is one of its most significant advantages. It enables a higher flow rate of fluids, resulting in improved efficiency and reduced pressure drop across the filter element.

2. Sintered structure. The sintered titanium felt filtration material consists of a three-dimensional network of interconnected titanium fibers, forming a dense and uniform structure. This unique structure provides excellent filtration efficiency, capturing even the smallest particles and impurities.

3. High strength and durability. High permeability sintered titanium felt exhibits exceptional mechanical strength and durability, making it suitable for use in high-pressure and high-temperature applications. Its excellent resistance to corrosion and chemical reactions further enhances its lifespan and reliability.

4. Easy to clean and maintain. The open structure of high permeability sintered titanium felt allows for efficient backwashing and cleaning, ensuring prolonged service life and reduced downtime. This makes it a cost-effective solution for long-term use.

5. Customizable. High permeability sintered titanium felt can be customized to meet specific application requirements. It can be tailored to various shapes, sizes, and thicknesses, making it a versatile solution for a wide range of filtering applications.

Applications

The high permeability sintered titanium felt filtration material finds numerous applications across various industries, including:

1. Water treatment. The high permeability sintered titanium felt filtration material is widely used in water treatment plants for removing impurities, bacteria, and viruses from water.

2. Oil and gas industry. This advanced filtration material is used in the oil and gas industry for separating impurities, such as dust, sand, and solid particles, from crude oil and natural gas.

3. Pharmaceutical industry. The high permeability sintered titanium felt filtration material is used in the pharmaceutical industry for filtering and purifying various pharmaceutical products, such as drugs, vaccines, and serums.

4. Food and beverage industry. This innovative filtration material is used in the food and beverage industry for removing impurities and maintaining the quality of various food products, such as juices, wines, and beers.

5. Chemical industry. The high permeability sintered titanium felt filtration material is used in the chemical industry for filtering and purifying various chemical substances, such as acids, bases, and solvents.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português