Product Details

The sintered metal titanium fiber felt can be used as a filtration material in high efficiency liquid filtration. This innovative filtration solution is designed to provide high efficiency, low pressure drop, and excellent resistance to a wide range of chemicals and temperatures.

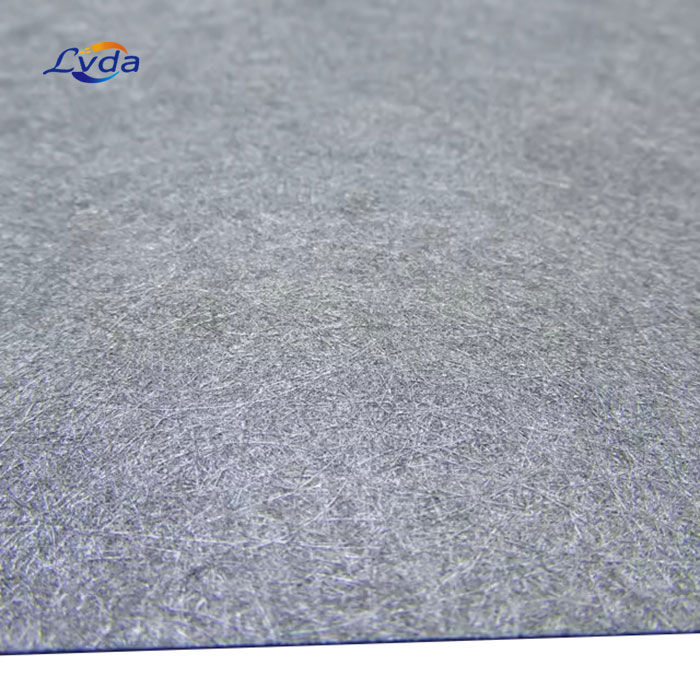

The high efficiency liquid filtration sintered metal titanium fiber felt is made from fine titanium fibers that are randomly arranged and interconnected, forming a three-dimensional network structure. This structure allows the filtration felt to have a high surface area, which in turn enables it to provide superior filtration efficiency. The titanium fibers used in the filtration felt are produced through a unique manufacturing process that involves electrospinning, fiber drawing, and sintering. These fibers exhibit excellent mechanical strength, thermal stability, and corrosion resistance, making them ideal for use in demanding filtration applications.

Parameters

Thickness : 0.2mm - 5mm

Porosity : 60% - 80%

Color : Gray

Filtration Rating : 1μm - 100μm

Shape : Square, rectangle, round

Place of Origin : Henan, China

Condition : New

Attributes

The high efficiency liquid filtration sintered metal titanium fiber felt possesses several unique properties that make it stand out from conventional filtration materials. Some of these properties include:

1. High filtration efficiency. The felt's three-dimensional network structure and small pore size enable it to filter out particles as small as 0.1 microns, making it suitable for high-purity applications.

2. Low pressure drop. The felt's open structure and high porosity result in a low pressure drop across the filter, reducing energy consumption and improving overall system efficiency.

3. High thermal stability. The titanium fibers used in the filtration felt exhibit excellent thermal stability, withstanding temperatures up to 600°C, making it suitable for use in high-temperature processes.

4. Corrosion resistance. The filtration felt is highly resistant to corrosion, making it suitable for use in aggressive chemical environments.

5. Reusability. The filtration felt can be cleaned and reused multiple times, reducing waste and lowering the overall cost of filtration.

Applications

The high efficiency liquid filtration sintered metal titanium fiber felt finds applications in various industries, including:

1. Pharmaceutical industry. The filtration felt is used to filter liquids and gases in the production of drugs and pharmaceutical products, ensuring high purity and compliance with regulatory standards.

2. Food and beverage industry. The filtration felt is used to filter beverages, edible oils, and other food products, ensuring the removal of impurities and maintaining product quality.

3. Chemical industry. The filtration felt is used in the production of chemicals, such as acids, bases, and solvents, to remove impurities and maintain product purity.

4. Water treatment. The filtration felt is used in water treatment plants to remove suspended solids, bacteria, and viruses from water, ensuring the provision of clean and safe water.

5. Energy industry. The filtration felt is used in power plants and other energy production facilities to filter cooling water, boiler feedwater, and other process fluids, reducing fouling and improving system efficiency.

Advantages

1. Higher filtration efficiency. The filtration felt provides higher efficiency compared to conventional filters, enabling the removal of smaller particles and ensuring higher-purity products.

2. Lower pressure drop. The filtration felt exhibits a lower pressure drop compared to traditional filters, reducing energy consumption and improving system efficiency.

3. Chemical and thermal resistance. The filtration felt is highly resistant to chemicals and heat, making it suitable for use in aggressive environments and high-temperature processes.

4. Reusability. Unlike traditional filters, the filtration felt can be cleaned and reused multiple times, reducing waste and lowering the overall cost of filtration.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português