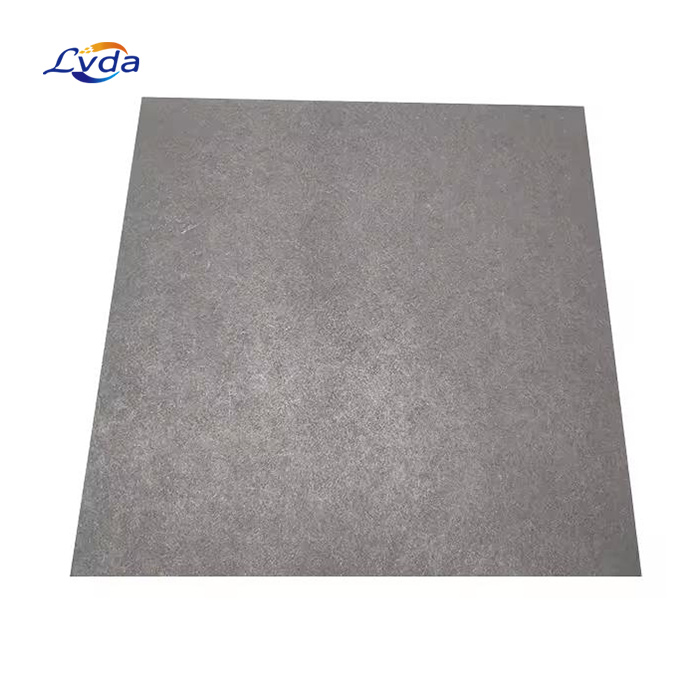

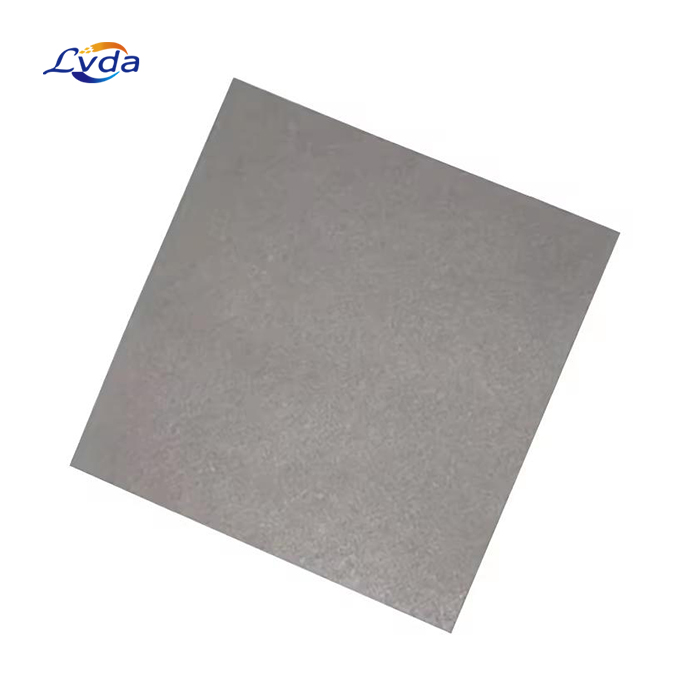

Product Details

High porosity porous pure titanium fiber felt has emerged as a promising material for PEM fuel cells due to its unique properties, such as high surface area, excellent chemical stability, and low electrical resistance.

PEM fuel cells operate by electrochemically converting the chemical energy of hydrogen and oxygen into electrical energy and water. The key components of a PEM fuel cell include the anode, cathode, and proton exchange membrane (PEM). The performance of PEM fuel cells is highly dependent on the properties of these components, and researchers have been working to develop advanced materials to enhance their performance.

Parameters

Ti Content : 99.5%

Porosity : 60% - 80%

Shape : Round, square, etc

Working Temperature : ≤300°C

Place of Origin : Henan, China

Properties of High Porosity Porous Pure Titanium Fiber Felt

High porosity porous pure titanium fiber felt is a three-dimensional network of interconnected titanium fibers with a high surface area and porosity. The porosity of the material can be tailored to achieve a desired level of performance, depending on the specific application. The key properties of high porosity porous pure titanium fiber felt that make it an attractive material for PEM fuel cells include:

1. High surface area. The high surface area of the titanium fiber felt provides an extensive reaction site for the electrochemical reactions occurring in the fuel cell, leading to improved performance.

2. Excellent chemical stability. Pure titanium is known for its excellent chemical stability and resistance to corrosion in acidic and alkaline environments. This makes it an ideal material for PEM fuel cells, which operate in a highly corrosive environment.

3. Low electrical resistance. High porosity porous pure titanium fiber felt exhibits low electrical resistance, which is crucial for minimizing the voltage loss in the fuel cell and improving its overall efficiency.

4. High thermal stability. The thermal stability of pure titanium ensures that the fiber felt maintains its structural integrity and performance under high-temperature operating conditions.

5. Easy fabrication. High porosity porous pure titanium fiber felt can be easily fabricated using various techniques, such as electrospinning, sol-gel processing, and powder metallurgy.

Applications of High Porosity Porous Pure Titanium Fiber Felt in PEM Fuel Cells:

1. Gas diffusion layers. High porosity porous pure titanium fiber felts are used as GDLs in PEM fuel cells, providing efficient gas transport and diffusion, good electrical conductivity, and effective heat dissipation.

2. Current collectors. Due to their excellent electrical conductivity, high porosity porous pure titanium fiber felts can also be used as current collectors in PEM fuel cells, facilitating the efficient transfer of electrons within the cell.

3. Support structures. High porosity porous pure titanium fiber felts can be used as support structures for other fuel cell components, such as the catalyst layer and membrane, providing mechanical strength and stability to the fuel cell system.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português