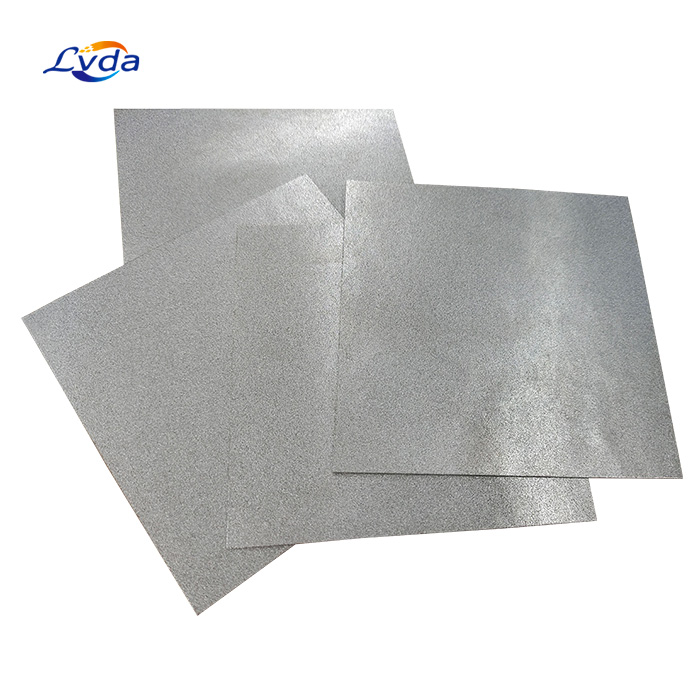

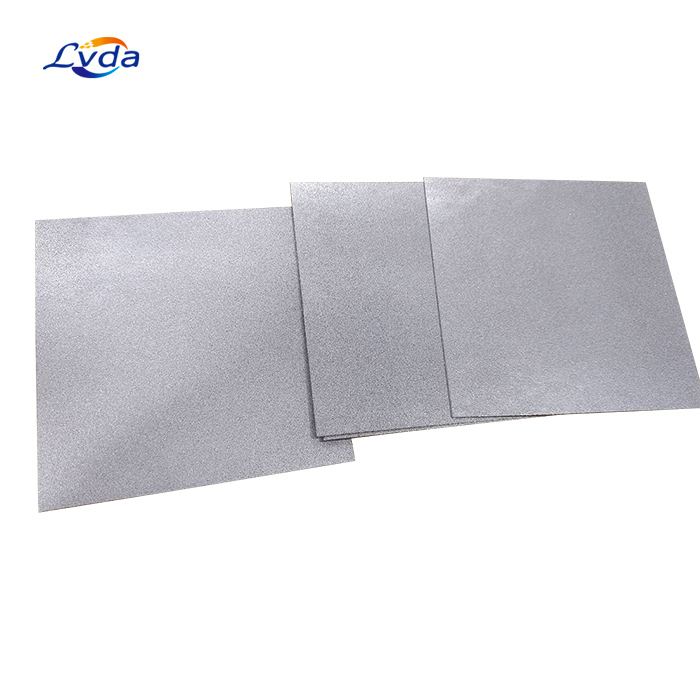

Product Details

The ruthenium-iridium coated sintered titanium fiber felt for filters is a cutting-edge technology that has been designed to provide superior performance in various filtration applications. This innovative product combines the unique properties of ruthenium and iridium, two precious metals, with the exceptional characteristics of sintered titanium fibers. The result is a filtration material that offers excellent efficiency, durability, and resistance to aggressive environments.

The manufacturing process of ruthenium-iridium coated sintered titanium fiber felt involves several key steps. First, high-purity titanium fibers are selected and carefully cleaned to remove any surface impurities. These fibers are then arranged in a random orientation to form a felt-like structure, which is subsequently compressed and sintered at high temperatures. The sintering process fuses the individual fibers together, creating a porous and mechanically strong matrix.

Once the sintered titanium fiber felt is formed, it undergoes a coating process where a mixture of ruthenium and iridium is applied to the surface. This coating is typically done using chemical vapor deposition (CVD) or physical vapor deposition (PVD) techniques, which ensure a uniform and adherent layer of the precious metals. The thickness of the coating can be tailored to meet specific application requirements, with typical ranges between a few micrometers to several tens of micrometers.

The combination of titanium, ruthenium, and iridium in this material provides several advantageous properties. Titanium offers excellent corrosion resistance and a high melting point, making it suitable for high-temperature applications. Ruthenium and iridium, on the other hand, are known for their exceptional chemical inertness and ability to catalyze certain reactions. When these metals are coated onto the sintered titanium fiber felt, they endow the material with an enhanced resistance to chemical attack and an improved surface for catalysis or electrical conductivity.

The porous structure of the ruthenium-iridium coated sintered titanium fiber felt allows it to function as an effective filter. The small pores between the fibers enable the material to trap particles and contaminants while allowing gases or liquids to pass through. The precise pore size can be controlled during the manufacturing process to target specific particle sizes for filtration. Additionally, the coating of ruthenium and iridium may provide additional mechanisms for capturing or reacting with certain species, further enhancing the filter's efficiency.

Parameters

Material : Titanium

Ti Content : 99.95%

Purity : 99.9%

Porosity : 50%-70%

Size : 100×100mm, 200×200mm, 300×300mm, 400×400mm or as request

Properties and Characteristics

ruthenium-iridium coated sintered titanium fiber felt for filters exhibits several unique properties and characteristics that make it an ideal material for various filtration applications:

1. High filtration efficiency. The small pore size and high surface area of the felt enable it to capture particles with high efficiency, making it suitable for applications that require clean and pure output.

2. Excellent chemical resistance. The ruthenium and iridium coatings provide superior resistance to aggressive chemicals, acids, and alkalis, allowing the felt to maintain its performance in harsh environments.

3. High thermal stability. The sintered titanium fibers and precious metal coatings exhibit excellent thermal stability, making the felt suitable for use in high-temperature applications.

4. Good mechanical strength. The felt has high tensile strength and durability, ensuring that it can withstand the stresses associated with filtration processes.

Applications

ruthenium-iridium coated sintered titanium fiber felt for filters finds applications in various industries and filtration processes, including:

1. Water treatment. The felt is used to filter impurities and particles from water, ensuring clean and safe water for residential, commercial, and industrial use.

2. Air pollution control. The felt is employed in industrial chimneys and exhaust systems to capture particulate matter, such as dust and soot, reducing emissions and protecting the environment.

3. Pharmaceutical and biotechnology. The felt is used in the production of pharmaceuticals and biological products, where high purity and stringent cleanliness requirements must be met.

4. Food and beverage. The felt is employed in the filtration of food and beverage products, ensuring the removal of unwanted particles and contaminants.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português