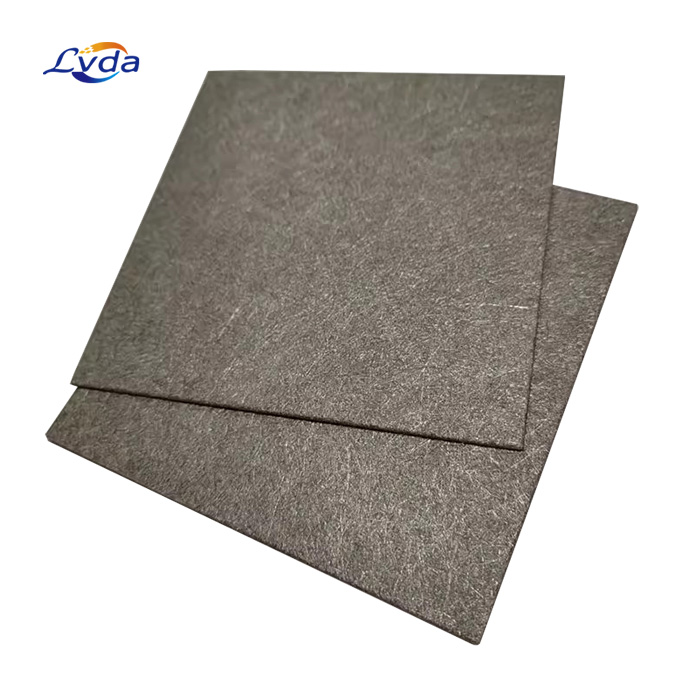

Product Details

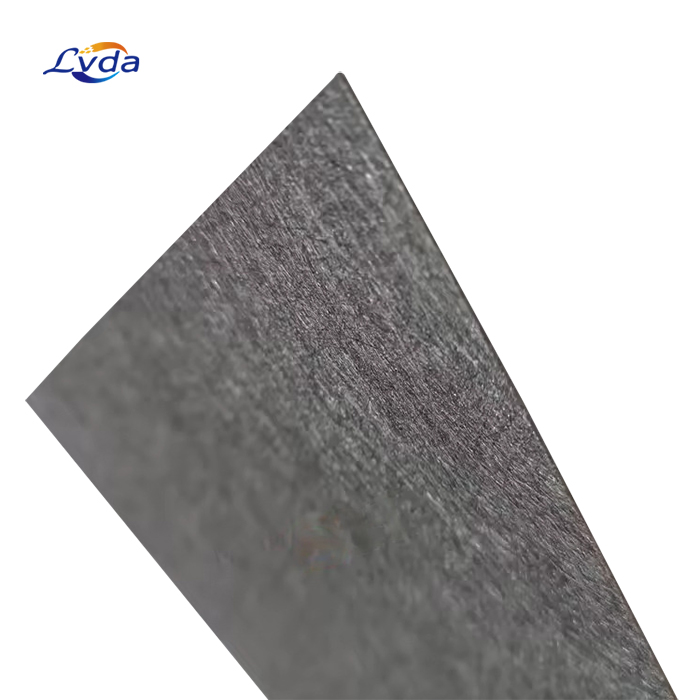

Sintered metal titanium fiber felt is a type of metal fabric made from fine titanium fibers. The material's unique 3D mesh porous structure is achieved through a carefully controlled manufacturing process, which involves the sintering of titanium fibers at high temperatures. This results in a felt-like material with a dense network of interconnected pores, providing exceptional filtering and mechanical properties.

Parameters

Thickness : 0.2 - 1mm (common size 0.25mm, 0.4mm, 0.6mm, 0.8mm, 1mm)

Porosity : 50%, 60%, 70%, 80%

Size : Customizable

Filter accuracy : 10um ,20um,30um,40um,50um,60um

Structure and Manufacturing Process

The sintered metal felt titanium fiber felt is produced through a multi-step manufacturing process. It starts with the selection of high-quality titanium fibers, which are then processed using specialized techniques to create a fibrous matrix. These fibers are intertwined and interconnected in a three-dimensional mesh structure, forming a uniform and continuous network.

Next, the titanium fiber matrix is subjected to a sintering process. Sintering involves heating the material to a controlled temperature below the melting point of titanium. During this process, the titanium fibers fuse together at their contact points, creating a solid and stable structure. The sintering process also helps in enhancing the mechanical strength and stability of the material.

Properties

1. 3D Mesh Porous Structure

The sintered metal titanium fiber felt possesses a highly interconnected 3D mesh porous structure. This unique structure provides a large surface area and enables efficient flow of fluids or gases, making it ideal for filtration and separation applications. The porous structure also allows for high dirt-holding capacity and low pressure drop.

2. High Temperature Resistance

Titanium has excellent heat resistance properties, enabling the sintered metal titanium fiber felt to withstand high temperatures. It remains stable and retains its structural integrity even under extreme thermal conditions, making it suitable for applications involving hot gases or liquids.

3. Corrosion Resistance

Titanium is known for its exceptional corrosion resistance. The sintered metal titanium fiber felt exhibits excellent resistance to various corrosive environments, including acids, alkalis, and organic solvents. This property makes it highly durable and long-lasting in harsh operating conditions.

4. Mechanical Strength

The sintered metal titanium fiber felt possesses high mechanical strength due to the sintering process. It can withstand high pressures and mechanical loads without deformation or breakage. This mechanical stability ensures consistent performance and extends the material's lifespan.

Applications

1. Filtration and Separation

The sintered metal titanium fiber felt is widely used in filtration systems for gas and liquid separation. Its 3D mesh porous structure allows for efficient removal of fine particles, contaminants, and impurities. It finds applications in industries such as pharmaceuticals, petrochemicals, food and beverages, and wastewater treatment.

2. Catalysis

The high surface area and porosity of the sintered metal titanium fiber felt make it an excellent catalyst support material. It provides a large active surface for catalytic reactions, enhancing reaction rates and efficiency. It is used in various catalytic processes, including hydrogenation, oxidation, and chemical synthesis.

3. High-Temperature Applications

The heat resistance of the sintered metal titanium fiber felt makes it suitable for applications involving high-temperature gases or liquids. It is used in industries such as power generation, aerospace, and metallurgy, where it acts as a filter or heat exchanger element.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português