Product Details

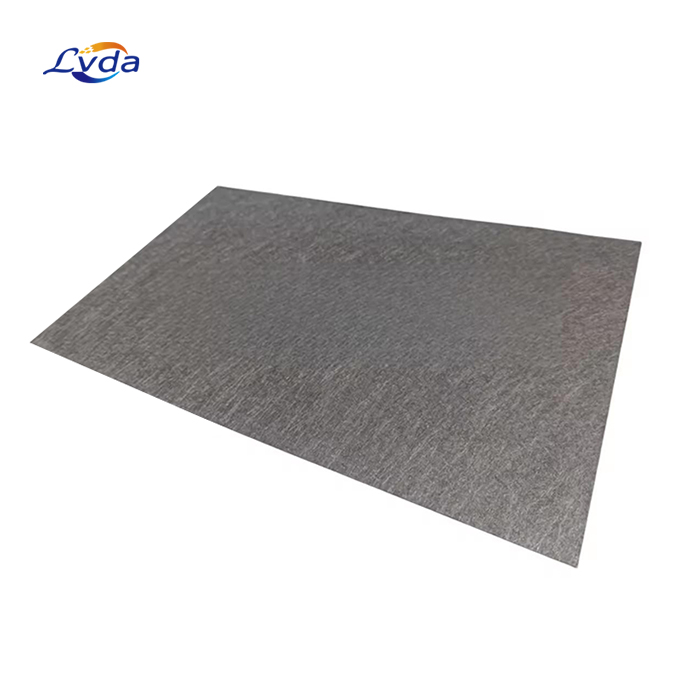

The 0.2mm thickness high porosity titanium fiber sintered felt battery material is composed of fine titanium fibers, which are tightly packed and interconnected to form a three-dimensional network structure. The unique structure of these materials allows for excellent electrical and thermal conductivity, as well as high mechanical strength. Additionally, the high porosity of the titanium fiber sintered felt enables a large surface area, which is crucial for improving the overall performance of batteries.

Parameters

Porosity : 60% - 80%

Thickness : 0.2mm

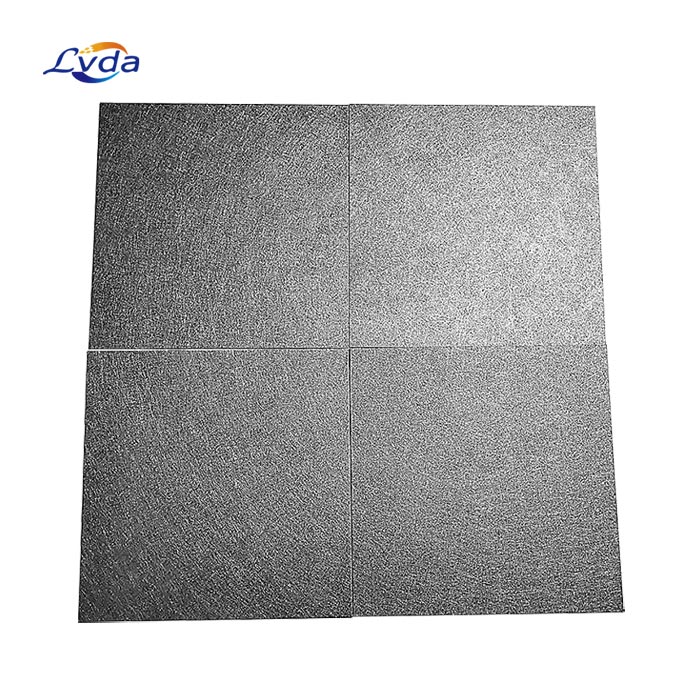

Shape : Square, rectangle, round, etc

Temperature : ≤800°C

Manufacturing Process

The manufacturing process of 0.2mm thickness high porosity titanium fiber sintered felt battery materials involves several steps:

1. Fiber preparation. The first step is to prepare the titanium fibers, which are obtained through a specialized drawing process. The fibers are then treated with a surface agent to enhance their wettability and improve the bonding between the fibers.

2. Felt formation. The prepared titanium fibers are randomly oriented and compacted to form a non-woven felt structure. This process ensures a high degree of porosity and a large surface area.

3. Sintering. The felt is then subjected to a high-temperature sintering process, during which the fibers are partially melted and bonded together. This process results in a dense, interconnected network structure that exhibits excellent mechanical and electrical properties.

4. Post-processing. After sintering, the material undergoes additional processing, such as cutting and shaping, to meet the specific requirements of the intended application.

Attributes

The 0.2mm thickness high porosity titanium fiber sintered felt battery materials exhibit several exceptional properties, making them ideal for various applications:

1. High electrical conductivity. The interconnected network structure of the titanium fibers ensures excellent electrical conductivity, which is essential for efficient charge and discharge in batteries.

2. High thermal conductivity. The sintered felt material exhibits high thermal conductivity, allowing for efficient heat dissipation during battery operation, which is crucial for maintaining optimal performance and safety.

3. High mechanical strength. The dense network structure of the sintered felt provides high mechanical strength, making it suitable for use in various battery designs and applications.

4. Large surface area. The high porosity of the titanium fiber sintered felt enables a large surface area, which is essential for improving the electrochemical performance of batteries, such as increased capacity and enhanced cycling stability.

5. Excellent corrosion resistance. Titanium is known for its excellent corrosion resistance, making the sintered felt material suitable for use in aggressive chemical environments.

Application

Applications of the 0.2mm thickness high porosity titanium fiber sintered felt battery materials include:

1. Lithium-ion batteries. The exceptional properties of these materials make them ideal for use as current collectors in lithium-ion batteries, improving their overall performance and efficiency.

2. Fuel cells. The high electrical and thermal conductivity of the sintered felt material make it suitable for use in fuel cells, where it can enhance the electrochemical reactions and improve the overall efficiency of the system.

3. Supercapacitors. The high mechanical strength and large surface area of the titanium fiber sintered felt make it an excellent material for use in supercapacitors, where it can improve the energy storage capacity and cycling stability.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português