Product Details

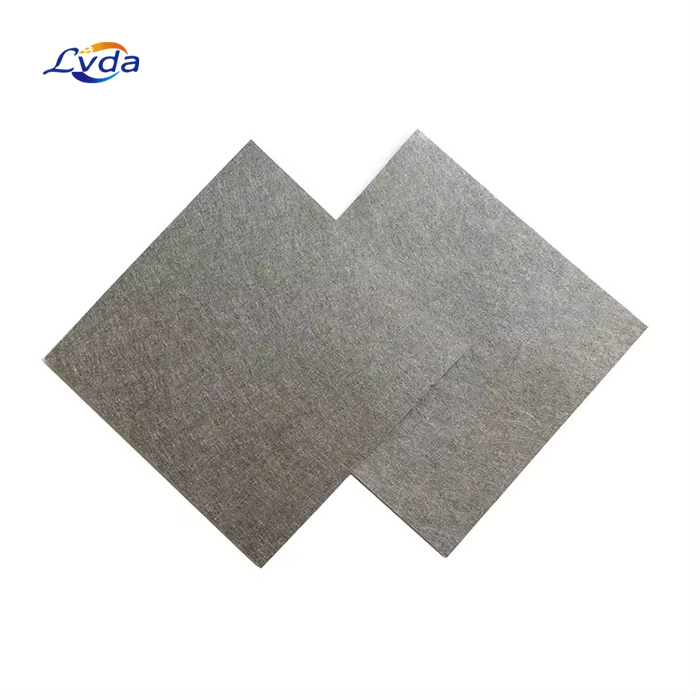

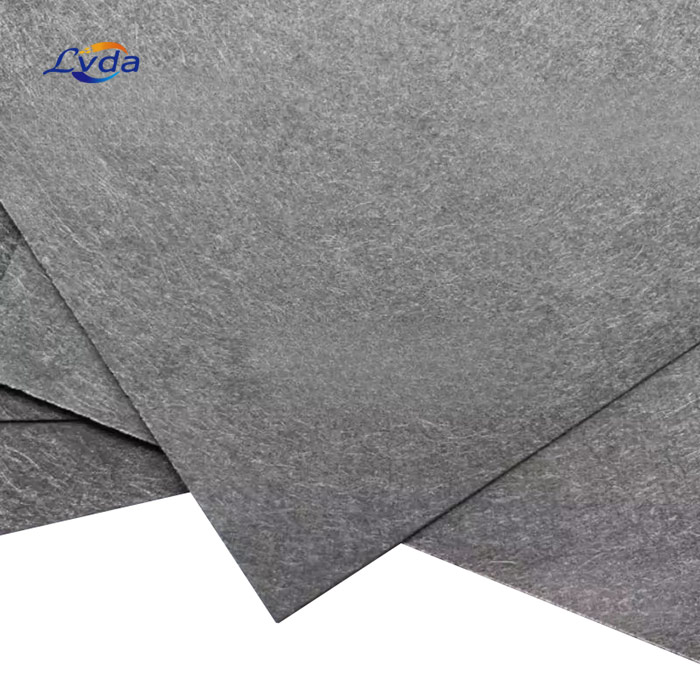

Titanium fiber felt is a unique material that has gained popularity in various industrial applications, particularly in the field of small hydrogen generators. This innovative material combines the strength and durability of titanium with the flexibility and porosity of felt, making it an ideal choice for hydrogen generation systems. Titanium fiber felt is made from pure titanium fibers that are woven or felted together to create a flexible, porous material. The thickness of the felt can range from 0.25mm to 0.8mm, depending on the specific requirements of the application.

Properties

Some of the key properties of titanium fiber felt include:

1. High strength. Titanium is known for its exceptional strength and durability, even at high temperatures. This makes titanium fiber felt an ideal material for use in harsh environments, such as those found in hydrogen generators.

2. Corrosion resistance. Titanium is highly resistant to corrosion, even in the presence of strong acids and alkalis. This property makes titanium fiber felt an excellent choice for use in hydrogen generators, where corrosive gases and liquids may be present.

3. Thermal stability. Titanium fiber felt has excellent thermal stability, meaning it can withstand high temperatures without losing its structural integrity. This is important in hydrogen generators, where temperatures can reach several hundred degrees Celsius.

4. Electrical conductivity. Titanium is a good conductor of electricity, which makes titanium fiber felt suitable for use in electrochemical processes, such as those involved in hydrogen generation.

5. Porous structure. The felted structure of titanium fiber felt provides a large surface area and high porosity, which is essential for efficient gas and liquid diffusion in hydrogen generators.

Parameters

Material : Titanium

Ti Content (%) : 99.99%

Thickness : 0.25mm, 0.4mm, 0.6mm, 0.8mm

Porosity : 60%-70%

Size : 650mm×650mm or customized

Technique : Sintering

Benefits

The use of high-quality 0.25-0.8mm thickness titanium fiber felt in small hydrogen generators offers several benefits, including:

1. Improved hydrogen production efficiency. The high porosity and large surface area of the felt ensure an efficient diffusion of reactants and products, leading to improved hydrogen generation efficiency.

2. Enhanced durability. The excellent chemical stability and corrosion resistance of the felt ensure a long service life and minimal maintenance requirements, reducing the overall operating costs of the hydrogen generator.

3. Reduced size and weight. The thinness and flexibility of the felt allow for the design of compact and lightweight hydrogen generators, making them more suitable for various applications, such as portable devices and vehicles.

4. Easy integration. The high-quality titanium fiber felt can be easily integrated into existing hydrogen generator designs, minimizing the need for costly and time-consuming redesign processes.

Applications of Titanium Fiber Felt in Small Hydrogen Generators

Titanium fiber felt has several applications in small hydrogen generators, including:

1. Electrolysis cells. Titanium fiber felt can be used as a cathode or anode in electrolysis cells, where it provides a large surface area for the electrochemical reactions that produce hydrogen gas. The porous structure of the felt allows for efficient gas diffusion and collection.

2. Catalyst supports. In some hydrogen generators, titanium fiber felt can be impregnated with catalysts that promote the production of hydrogen gas. The felt provides a stable support for the catalyst particles, while also allowing for efficient gas diffusion.

3. Heat exchangers. Titanium fiber felt can be used as a heat exchanger material in hydrogen generators, where it efficiently transfers heat between different parts of the system. This helps to maintain optimal operating temperatures and improve overall system efficiency.

4. Gas diffusion layers. In fuel cell-based hydrogen generators, titanium fiber felt can be used as a gas diffusion layer, where it facilitates the transport of hydrogen gas to the fuel cell's catalyst layer. This helps to maximize the efficiency of the fuel cell and improve overall system performance.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português