Product Details

In the realm of fuel cells and other electrochemical devices, the liquid/gas diffusion layer (LGDL) plays a critical role in facilitating the transport of reactants and products between the catalyst layer and the flow channels. The LGDL must be both electrically conductive and porous to ensure efficient mass transfer while maintaining structural integrity. Platinized titanium fiber felt is one such material that has gained attention due to its unique properties that make it suitable for use as an LGDL electrode material.

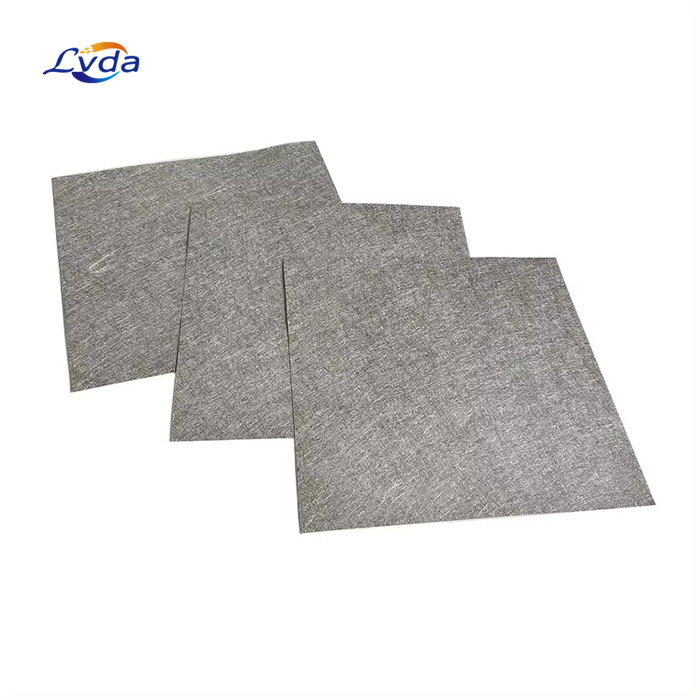

What is Platinized Titanium Fiber Felt?

Platinized titanium fiber felt is a composite material composed of a titanium fiber felt substrate that has been coated with a thin layer of platinum (Pt). The titanium fiber felt is made from interwoven titanium fibers, creating a porous, flexible matrix. This substrate is then platinized, which involves depositing a thin layer of platinum onto the surface of the titanium fibers.

Parameters

Base material : Pure titanium fiber

Thickness : 0.20mm, 0.25mm, 0.40mm, 0.60mm, 0.80mm, etc

Porosity : 60%–80%

Size : ≤1500*1200mm

Platinum coated thickness : 0.5 micron

Filtration accuracy : 1-200um

Working strength : 0.1-30MPa

Properties of Platinized Titanium Fiber Felt

- Electrical Conductivity

The addition of platinum to the titanium fiber felt significantly enhances its electrical conductivity. Platinum is a highly conductive metal, and when deposited onto the titanium fibers, it creates a continuous network that facilitates electron transfer within the LGDL. This is crucial for maintaining low-resistance pathways for the current generated during electrochemical reactions.

- Chemical Stability

Titanium is known for its excellent corrosion resistance, especially in oxidizing environments. When platinized, the titanium fiber felt retains this chemical stability while gaining additional protection from the inert platinum layer. This makes the material suitable for use in harsh electrochemical environments where other materials might degrade over time.

- Mechanical Strength

The interwoven structure of the titanium fiber felt provides the material with good mechanical strength and flexibility. This allows it to withstand the stresses associated with handling, installation, and operation in fuel cells or other electrochemical devices without compromising its structural integrity.

- Porous Structure

The porous nature of the titanium fiber felt is essential for the LGDL's function. The pores allow for the unimpeded flow of reactants and products, ensuring that the catalyst layer is adequately supplied with necessary chemicals and that waste products are efficiently removed. The pore size and distribution can be tailored during the manufacturing process to meet specific requirements of different applications.

- Hydrophobicity

Platinized titanium fiber felt often exhibits hydrophobic properties, which can be beneficial in certain applications. A hydrophobic surface can reduce the likelihood of flooding, a phenomenon where liquid water accumulates on the LGDL and impedes the flow of reactants. This property can be further enhanced through surface treatments or by incorporating hydrophobic additives into the felt matrix.

Applications

Platinized titanium fiber felt is primarily used in the following applications:

- Fuel Cells

As an LGDL material in fuel cells, platinized titanium fiber felt facilitates the transport of hydrogen and oxygen, as well as the removal of water and heat. Its high electrical conductivity, chemical stability, and porous structure make it an ideal candidate for this role.

- Electrolyzers

Similar to fuel cells, electrolyzers also require efficient LGDL materials for the transport of reactants and products. Platinized titanium fiber felt can be used in electrolyzers for the production of hydrogen or other gases through the process of water electrolysis.

- Electrochemical Reactors

In various electrochemical reactors, platinized titanium fiber felt can serve as a stable and conductive support for catalysts, enhancing the overall performance of the reactor by providing a large surface area for chemical reactions to occur.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português