Product Details

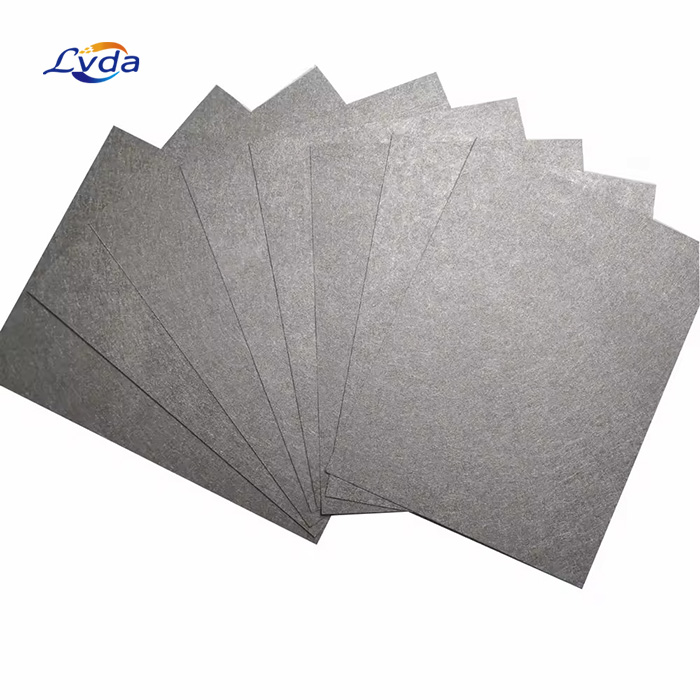

PEM Water Electrolysis 50%-80% Porosity Sintered Titanium Fiber Felt is a highly specialized material designed for use in Proton Exchange Membrane (PEM) water electrolyzers, which are advanced devices that convert electricity into hydrogen and oxygen through the process of electrolysis. This innovative felt is composed of titanium fibers that have been sintered to create a porous structure with a porosity range of 50% to 80%. This unique characteristic allows it to play a critical role in enhancing the efficiency, durability, and performance of PEM electrolyzers.

Parameters

Material : Titanium

Porosity : 50%, 55%, 65%, 70%, 80%

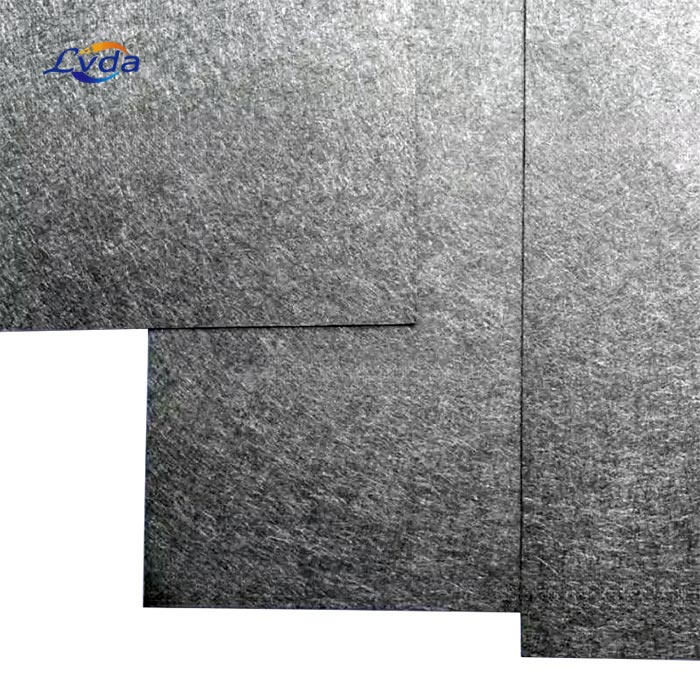

Thickness : 0.2mm - 5mm

Dimension : 500×1000mm / 600×1200mm / 1180×1540mm or customized

Filter Accuracy : 3-80μm

Color : Gray

Place of Origin : Henan, China

Condition : New

Material Composition

Sintered titanium fiber felt is made from pure titanium fibers, which are selected for their excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility. The fibers are processed using a sintering technique, where they are heated below their melting point to bond together while maintaining an interconnected porous network. This results in a robust yet flexible material that can withstand the harsh chemical environments found within PEM electrolyzers.

Porosity and Its Significance

The high porosity (50%-80%) is one of the most crucial aspects of this titanium felt. The large number of pores provides an extensive surface area that facilitates rapid gas diffusion and electron transfer during the electrolysis process. The porous structure allows for efficient transport of reactant gases (water), ions, and product gases (hydrogen and oxygen). It also enables effective cooling due to its enhanced heat dissipation properties, which is vital for maintaining optimal operating temperatures within the cell stack.

Large Dirt Holding Capacity

Another significant feature is its large dirt holding capacity. The porous nature of the titanium felt can trap impurities and contaminants present in the water supply, preventing them from reaching the sensitive catalyst layers or membrane in the PEM electrolyzer. This helps maintain the purity of the reaction environment, prolongs the lifespan of the electrolyzer components, and reduces maintenance requirements.

Role in PEM Water Electrolysis

In PEM electrolysis, the sintered titanium fiber felt typically serves as a gas diffusion layer (GDL). This layer sits between the catalyst-coated membrane (CCM) and bipolar plates. It ensures even distribution of hydrogen and oxygen gases produced at the electrodes, manages the water supply to the catalyst layer, and removes excess heat. Moreover, its electrical conductivity supports uniform current distribution across the electrode surfaces.

Performance Benefits

1. Enhanced Durability. The sintered titanium fibers ensure a long service life due to their inherent corrosion resistance and mechanical strength.

2. Improved Efficiency. By optimizing the flow of gases and electrolyte, the felt contributes to increased electrolysis rates and thus higher energy conversion efficiency.

3. Stable Operation. The ability to hold and manage contaminants minimizes the risk of short circuits or reduced performance caused by impurities.

4. Scalability. The flexibility and form factor of the felt make it suitable for various electrolyzer designs and scalable production of hydrogen.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português