Product Details

Pure titanium 60-70% porosity sintered titanium fiber felt for electrolyzer diffuser is a type of gas diffusion electrode material used in electrolyzers. Electrolyzers are devices that use electricity to break down water or other chemicals into their components. In the process of electrolysis, water undergoes a chemical reaction at the electrodes and breaks down into hydrogen and oxygen. Electrolyzer diffuser is a component used to facilitate the flow of gas and improve the efficiency of the electrolysis process.

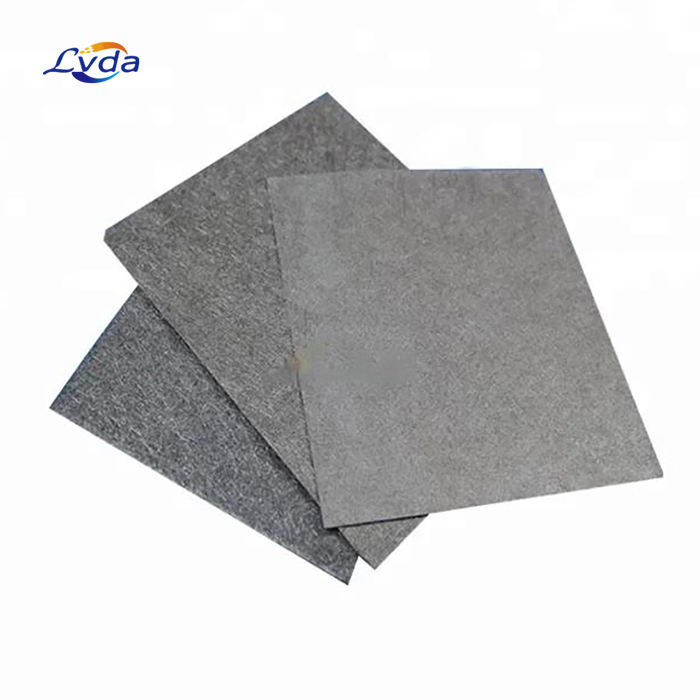

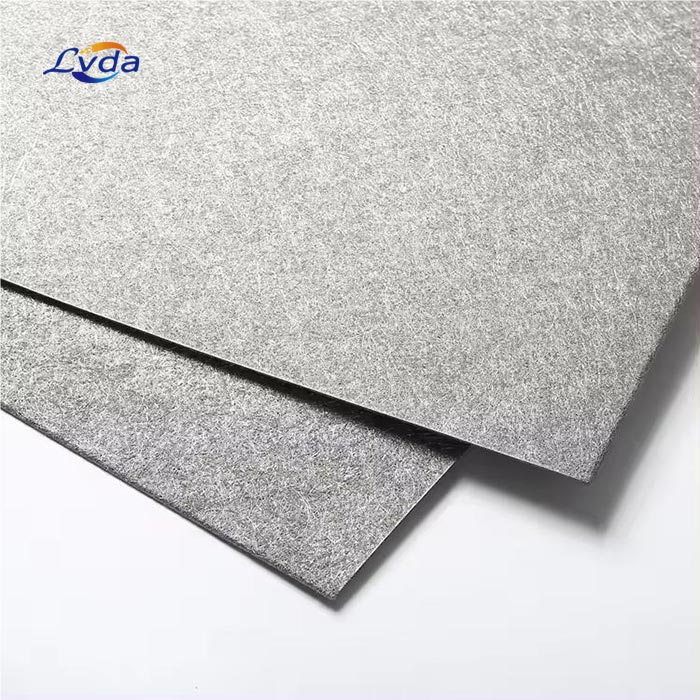

Titanium fiber felt, as the name suggests, is made from pure titanium fibers that are processed into a felt-like structure using specialized manufacturing techniques. The key feature of this product lies in its high porosity, ranging between 60-70%, which significantly enhances its surface area and thereby improves the efficiency of the electrolysis process.

Pure titanium is chosen for this application due to its exceptional properties. It boasts excellent corrosion resistance, particularly against acidic environments typically found in water electrolyzers, where hydrogen and oxygen are produced from water molecules. Moreover, titanium's strength-to-weight ratio, biocompatibility, and thermal stability make it an ideal candidate for long-term, durable use in harsh chemical conditions.

The sintering process used to create the titanium fiber felt involves laying down multiple layers of fine titanium fibers, followed by heat treatment under controlled conditions. This causes the fibers to bond together without melting, thus preserving their porous nature while creating a robust and stable structure. The result is a highly conductive, permeable matrix that optimizes the flow of reactants and products during electrolysis.

In the context of electrolyzer diffusers, the Pure Titanium 60-70% Porosity Sintered Titanium Fiber Felt serves as a crucial component. Its large surface area provides ample sites for electrochemical reactions, accelerating the rate at which water can be split into hydrogen and oxygen. The open-cell, porous structure facilitates efficient mass transfer, ensuring that both gases are produced effectively and can be easily separated and collected.

This felt also helps in maintaining uniform current distribution across the electrolyzer, reducing hot spots that can lead to decreased efficiency and premature failure. The high porosity allows for low-pressure drops, which in turn minimizes the energy required to pump the electrolyte solution through the cell, further enhancing overall system efficiency.

Furthermore, the flexibility and formability of the titanium fiber felt enable it to conform to various electrolyzer designs, including those based on Proton Exchange Membrane (PEM), Alkaline, or Solid Oxide Electrolysis Cell (SOEC) technologies. This adaptability makes it a versatile material choice for next-generation electrolyzers.

Parameters

Material : Titanium

Porosity : 60% - 70%

Thickness : As customer's request, 0.2mm - 2mm is available

Size : As customer's request

Technique : Sintering

Place of origin : Henan, China

Condition : New

Application

In addition to its use in electrolyzers, pure titanium 60-70% porosity sintered titanium fiber felt can also be used in other applications where a highly porous, chemically stable material is required. For example, it can be used as a filter in chemical processing plants, or as a support material for catalysts in industrial processes.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português