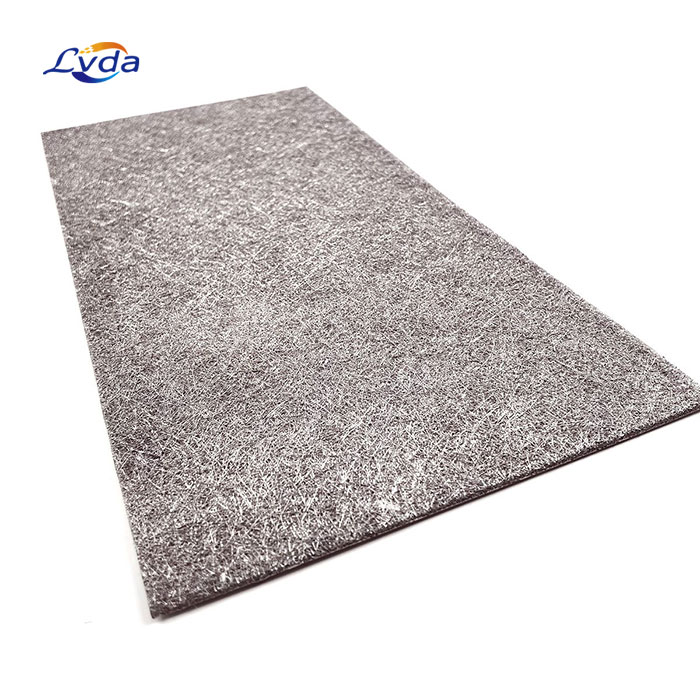

Product Details

The sintered titanium fiber felt is a type of porous material made from titanium fibers that have been compressed and heated to form a solid structure. The sintering process involves the application of heat below the melting point of the material, which allows the particles to bond together without fully melting. This process results in a dense, yet porous material with high mechanical strength and excellent chemical stability. As an innovative and high-performance material, the sintered titanium fiber felt boasts low price, high porosity and customizable size, specifically engineered for applications in fuel cell batteries and other advanced electrochemical devices.

Parameters

Shape : Rectangular sheet-like

Material : Titanium

Chemical Composition : Ti

Titanium Purity : 99%

Thickness : 0.1mm, 0.15mm, 0.25mm, 0.4mm, 0.6mm, 0.8mm, 1mm, etc.

Porosity : 50-78%

Titanium Fiber Diameter : 30-60 microns

Place of Origin : Henan, China

Material Properties and Characteristics

1. High Porosity

The high porosity of the sintered titanium fiber felt is a key feature that enhances its functionality in fuel cells. With a porosity typically ranging from 70% to 90%, it allows for unimpeded gas diffusion and ion transport, which are critical processes in fuel cell reactions. The open pore structure ensures efficient mass transfer of reactants and products, thus improving overall fuel cell performance and power density.

2. Customizable Size

This unique material can be manufactured in a wide array of sizes and thicknesses according to customer requirements. Its flexibility enables it to fit various fuel cell designs, including proton exchange membrane (PEM), solid oxide fuel cells (SOFCs), and direct methanol fuel cells (DMFCs). This adaptability reduces design constraints and contributes to more streamlined and efficient energy systems.

3. Sintered Titanium Fibers

The felt is composed of fine titanium fibers that undergo a sintering process. This results in a robust yet porous structure with excellent mechanical strength, thermal stability, and corrosion resistance. Titanium's inherent properties make it ideal for use in harsh chemical environments typical of fuel cell operations. It maintains its integrity under high temperatures, ensuring long-term durability and reliability.

4. Electrochemical Performance

The sintered titanium fiber felt acts as a substrate or electrode support in fuel cells, providing a large surface area for catalyst layers and facilitating electron transfer. The uniform distribution of pores and strong adherence to catalyst materials contribute to enhanced reaction kinetics and improved power output.

5. Cost-Effectiveness

Despite titanium being known for its high cost, this sintered titanium fiber felt offers a cost-effective solution due to its optimized material usage and extended lifespan. By maximizing efficiency and reducing replacement rates, it delivers significant savings over the life cycle of the fuel cell battery.

6. Manufacturing Process

The production process involves carding and laying down titanium fibers into a mat followed by compression and sintering at controlled temperatures. This ensures the interconnectivity and bonding between fibers without compromising porosity. The end result is a lightweight, flexible, and resilient felt that can withstand the rigors of fuel cell operation.

Applications

In fuel cell batteries, the Low Price High Porosity Customizable Size Sintered Titanium Fiber Felt is primarily used as:

- Bipolar plates for PEM fuel cells, where they serve as current collectors and provide channels for hydrogen and oxygen flow.

- Electrode supports in SOFCs, promoting gas diffusion and electron conduction.

- Catalyst supports in DMFCs, offering a stable platform for the catalytic reaction to occur.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português