Product Details

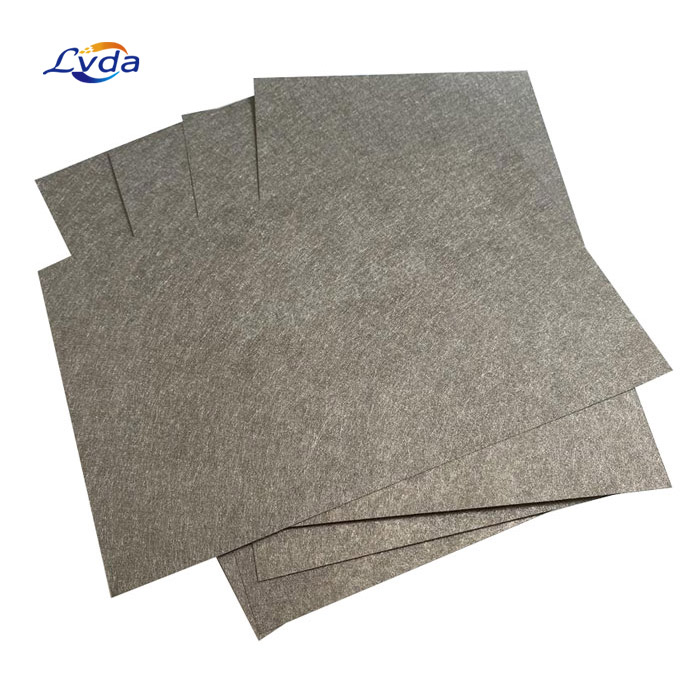

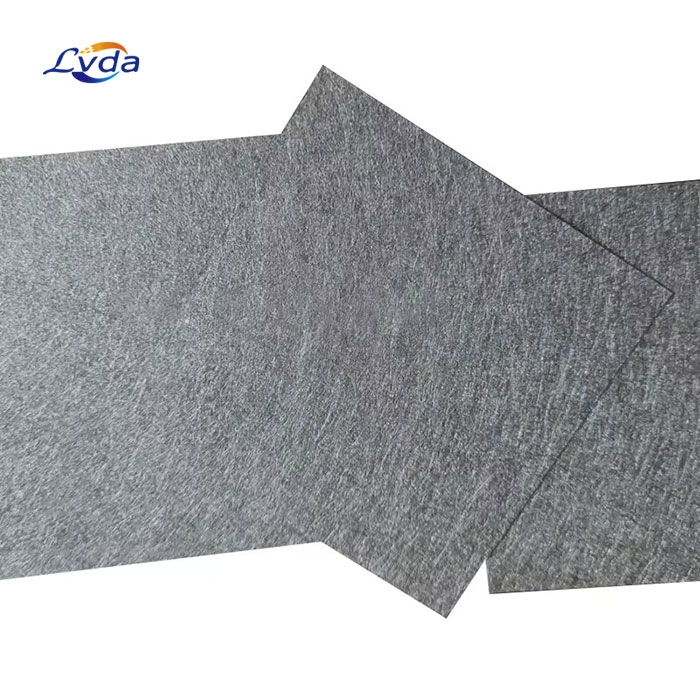

High temperature resistance porous metal sintered titanium felt is a remarkable material designed for gas and liquid filtration applications. This innovative material is characterized by its high porosity, excellent thermal stability, and exceptional chemical resistance, making it an ideal choice for a wide range of filtration applications across various industries.

Sintered titanium felt is made of titanium fibers that are carefully arranged and then subjected to a high-temperature sintering process, resulting in a highly porous, three-dimensional network structure. This unique structure provides excellent filtration performance, allowing for efficient flow rates and low pressure drop while effectively capturing particles and impurities.

Parameters

Material : Titanium

Thickness : 0.2mm - 2.5mm or customized

Size : 500×500 / 1000×500 / 1000×600 / 1000×1000 / 1200×1000 / 1500×1200mm or customized

Filter Rating : 1-300um

Place of Origin : Henan, China

Condition : New

Advantages

One of the primary advantages of sintered titanium felt is its high porosity, which enables efficient gas and liquid flow while maintaining a high level of filtration efficiency. The three-dimensional network structure of the material allows for the effective capture of particles and impurities, making it suitable for a wide range of filtration applications, including gas purification, liquid clarification, and separation processes. The high porosity of sintered titanium felt also contributes to its low pressure drop, resulting in reduced energy consumption and improved overall system efficiency.

Another significant advantage of sintered titanium felt is its excellent thermal stability. The material can withstand exposure to high temperatures. This property makes it an ideal choice for applications involving hot gases or liquids, such as flue gas cleaning, thermal processing, and high-temperature liquid filtration. The high temperature resistance of sintered titanium felt ensures that it maintains its structural integrity and filtration performance even in demanding operating conditions.

In addition to its high porosity and thermal stability, sintered titanium felt exhibits exceptional chemical resistance. Titanium is known for its ability to withstand exposure to various chemicals and corrosive environments without experiencing significant degradation. This property makes sintered titanium felt suitable for use in harsh chemical processing applications, such as acid and base filtration, as well as in aggressive industrial environments. The material's chemical resistance ensures a long service life and reduced maintenance requirements, making it a cost-effective solution for a variety of filtration applications.

Application

The use of high temperature resistance porous metal sintered titanium felt in gas and liquid filtration applications offers numerous benefits, including improved filtration efficiency, reduced energy consumption, and enhanced system reliability. Its unique combination of properties, such as high porosity, thermal stability, and chemical resistance, makes it an ideal choice for a wide range of industries, including:

1. Environmental protection: Sintered titanium felt can be used in flue gas cleaning systems, helping to reduce emissions from power plants and industrial facilities.

2. Chemical processing: The material's chemical resistance makes it suitable for use in the filtration of acids, bases, and other corrosive chemicals used in various chemical processing applications.

3. Energy production: Sintered titanium felt can be used in the filtration of gases and liquids in energy production processes, such as solar, wind, and nuclear power generation.

4. Oil and gas: The material's high temperature resistance and chemical stability make it suitable for use in the filtration of oils, hydrocarbons, and other fluids in oil and gas production and refining processes.

5. Biotechnology and pharmaceuticals: Sintered titanium felt can be used in the filtration of biological fluids and pharmaceutical products, ensuring the production of high-quality, contamination-free products.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português