Product Details

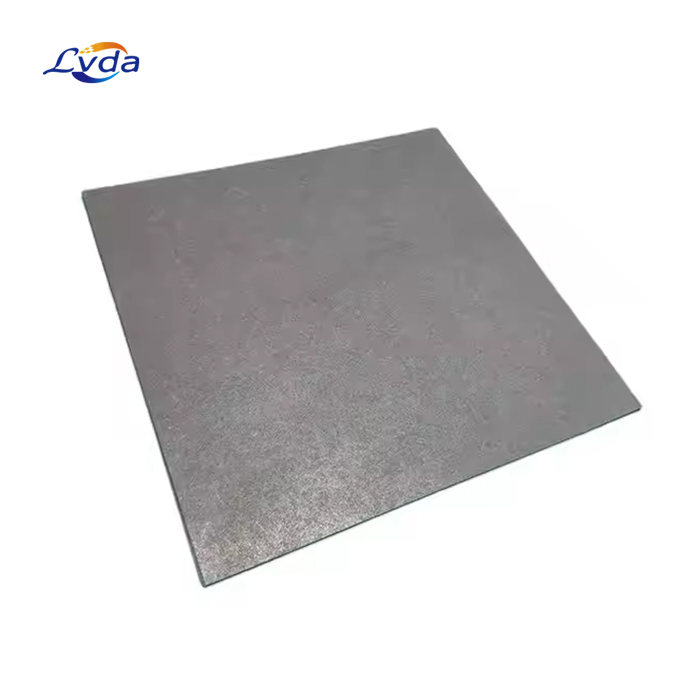

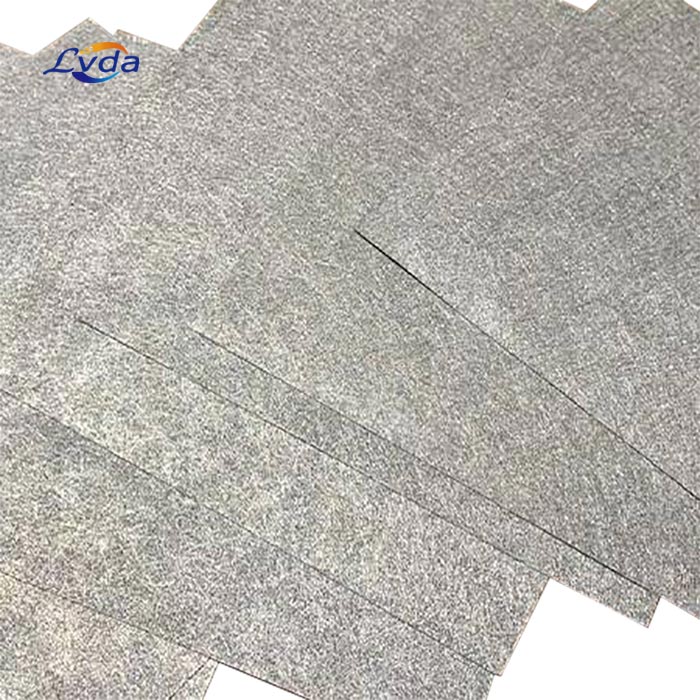

Sintered titanium fiber felt for hydrogen energy is a highly specialized material designed for hydrogen production by electrolysis. This innovative material is made of micron-sized titanium fibers, which are carefully stacked according to a special lay-up method. The fibers are then pressurized and sintered in a high-temperature vacuum environment, causing the nodes between the fibers to melt and eventually form a three-dimensional network structure. This unique structure enables the sintered titanium fiber felt to exhibit excellent performance in hydrogen production, making it an ideal choice for various electrolysis applications.

The development of hydrogen energy has become increasingly important in recent years, as it represents a clean, sustainable, and efficient energy source. Hydrogen can be produced through various methods, with electrolysis being one of the most promising techniques. Electrolysis involves the decomposition of water molecules into hydrogen and oxygen using an electric current. The efficiency and sustainability of the electrolysis process depend on the materials used in the electrodes and the overall design of the electrolyzer.

Sintered titanium fiber felt offers several advantages as an electrode material for hydrogen production by electrolysis. Firstly, its three-dimensional network structure provides a large surface area, enabling efficient electron transfer and mass transport. This results in improved electrochemical performance and increased hydrogen production. Secondly, the sintered titanium fiber felt is highly porous, allowing for better gas diffusion and reduced resistance to gas evolution. This leads to enhanced electrolysis efficiency and reduced energy consumption. Lastly, the material's high mechanical strength and chemical stability ensure its durability and reliability in harsh operating conditions.

In addition to its excellent performance in hydrogen production, sintered titanium fiber felt also exhibits outstanding corrosion resistance. This is crucial for electrolysis applications, as the materials used in the electrodes must be able to withstand the corrosive environment created by the electrolyte and the generated gases. The corrosion resistance of sintered titanium fiber felt ensures minimal material degradation and reduced maintenance requirements, making it a cost-effective solution for hydrogen production.

Furthermore, the sintered titanium fiber felt can be tailored to meet specific requirements by adjusting the fiber diameter, lay-up method, and sintering conditions. This allows for the optimization of the material's properties to suit various electrolysis applications, such as alkaline electrolysis, PEM (proton exchange membrane) electrolysis, and solid oxide electrolysis. The versatility of sintered titanium fiber felt makes it an attractive option for researchers and developers working in the hydrogen energy sector.

Parameters

Base material : Titanium fiber

Thickness : 0.2 - 0.8mm

Porosity : 60% - 80%

Filtration accuracy : 1 - 200um

Working strength : 0.1 - 30MPa

In conclusion, sintered titanium fiber felt for hydrogen energy is a highly specialized material designed for efficient hydrogen production by electrolysis. Its unique three-dimensional network structure, high porosity, excellent mechanical and chemical properties, and customizable nature make it an ideal choice for various electrolysis applications. As the demand for clean and sustainable energy sources continues to grow, the development and utilization of sintered titanium fiber felt will play a significant role in advancing hydrogen energy technology and promoting the widespread adoption of hydrogen as a primary energy carrier.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português