Product Details

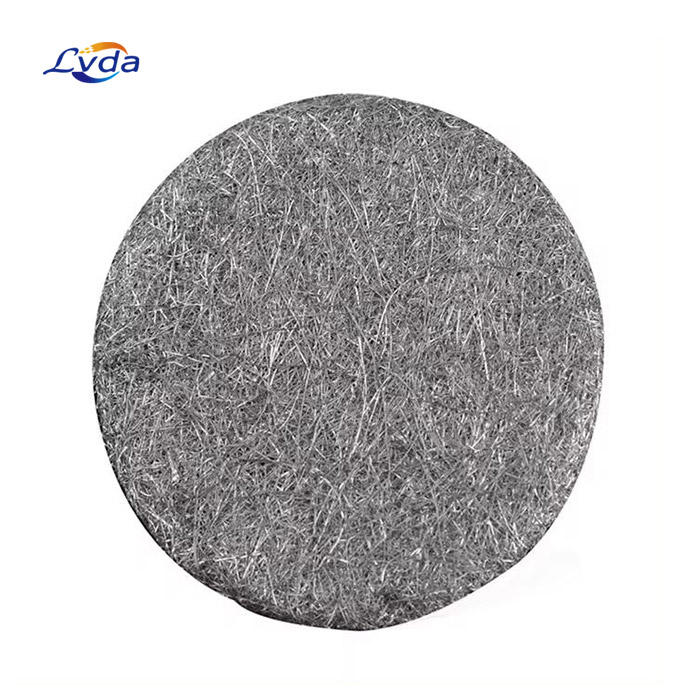

Round porous sintered titanium fiber felt platinum-coated titanium felt is a material commonly used in the electrochemical industry, particularly in proton exchange membrane (PEM) water electrolyzers. This type of felt is made by sintering fine titanium fibers to create a porous structure that provides a large surface area for reactions to occur. The porosity allows for efficient gas diffusion and can help in the uniform distribution of reactants and products within the cell.

Significance of platinization process

To understand the significance of platinum-coated sintered titanium felt, it is essential to delve into its composition and manufacturing process. Titanium felt is initially created through a sintering process, which involves compressing titanium fibers under high heat to form a porous and robust structure. This sintered titanium felt exhibits excellent mechanical strength and chemical stability, making it a suitable candidate for use in harsh environments such as those encountered in fuel cells.

The platinization process further enhances the performance of the titanium felt. Platinum, a noble metal, is deposited onto the surface of the sintered titanium felt through various techniques, such as electrochemical deposition or sputtering. This platinum coating not only improves the electrical conductivity of the felt but also enhances its catalytic activity, enabling it to effectively facilitate the electrochemical reactions that occur within the fuel cell.

Attributes

1. High porosity. The round porous sintered titanium fiber felt platinum-coated titanium felt has a high porosity, which enables it to provide excellent permeability for gases and liquids.

2. Excellent mechanical properties. The sintering process gives the material high mechanical strength and durability, making it suitable for use in various applications.

3. Good corrosion resistance. The use of high-purity titanium and the addition of a platinum coating make the material highly resistant to corrosion in aggressive environments.

4. High thermal conductivity. The material has good thermal conductivity, ensuring efficient heat dissipation in high-temperature applications.

Parameters

Porosity : 60% - 80%

Conventional size : 50*50mm

Shape : Round

Thickness : 0.2mm - 4mm

Purity : More than 99%

Advantages

1. High performance. The round porous sintered titanium fiber felt platinum-coated titanium felt offers excellent electrochemical performance, mechanical properties, and corrosion resistance, making it suitable for use in various applications.

2. Cost-effective. Despite its high-performance properties, the material is relatively cost-effective compared to other advanced materials, such as noble metal catalysts.

3. Versatility. The material can be used in various applications, including PEM water electrolysis, fuel cells, membrane reactors, and environmental protection, making it a versatile material for different industries.

Applications

The round porous sintered titanium fiber felt platinum-coated titanium felt is used as an electrode material in PEM water electrolyzers, where it exhibits excellent electrochemical performance and durability. Also, the material can be used as a gas diffusion layer (GDL) in fuel cells, providing good permeability for gases and efficient heat dissipation. The material, what’s more, can be used as a support for catalytic membranes in membrane reactors, offering high mechanical strength and excellent corrosion resistance.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português