Product Details

Hydrogen fuel cells are electrochemical devices that convert the chemical energy of hydrogen into electrical energy through a reaction with oxygen, typically from the air. A key component in the construction of these fuel cells is the gas diffusion layer (GDL), which plays a crucial role in ensuring the efficient transport of gases, electrons, and heat within the cell. One of the most commonly used materials for GDLs is platinized sintered titanium felt.

Platinized sintered titanium felt is a high-performance material that combines the benefits of titanium's robust structural properties with the catalytic efficiency of platinum. The process of manufacturing this material involves several key steps:

1. Titanium Felt Production

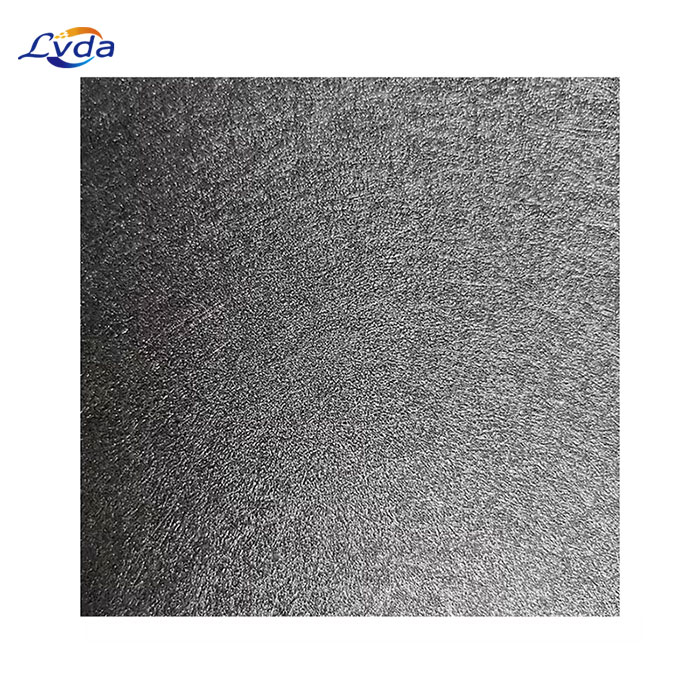

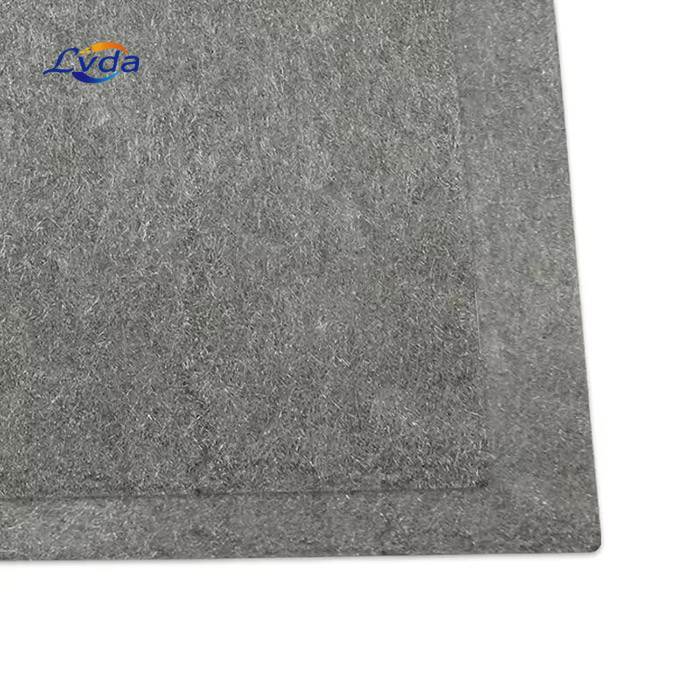

Titanium felt is produced by weaving fine titanium wires together to form a strong, porous structure. This felt provides excellent mechanical strength and stability, as well as a high surface area that is beneficial for gas diffusion and catalyst coating.

2. Sintering

Sintering is a high-temperature process where the titanium felt is heated to a point where the individual titanium fibers fuse together, creating a rigid and porous structure. This not only enhances the mechanical strength of the felt but also ensures that the pores remain stable under the operational conditions of the fuel cell.

3. Platinization

Platinization involves depositing a thin layer of platinum onto the surface of the sintered titanium felt. Platinum is an excellent catalyst for the hydrogen oxidation and oxygen reduction reactions that occur in fuel cells. The deposition process can be done through various methods such as sputtering, electroless plating, or chemical vapor deposition. The goal is to achieve a uniform distribution of platinum nanoparticles on the titanium fibers without blocking the pores.

4. Surface Treatment

After platinization, the surface of the felt may undergo further treatments to improve its performance. This can include roughening the surface to increase the effective surface area or applying additional layers of catalyst support materials like carbon powder to enhance electrical conductivity.

Some of the specifications for this device are as follows:

1. Porosity : 55% - 75%

2. Thickness : 0.25mm - 3.0mm

3. Place of Origin : Henan, China

4. Technique : Vacuum sintering

5. Dimension : As for customer' request

The resultant platinized sintered titanium felt GDL offers several advantages for use in hydrogen fuel cells:

1. High Porosity. The felt maintains a high porosity after sintering, which allows for efficient gas transport to and from the catalyst layer.

2. Good Electrical Conductivity. The titanium base provides inherent electrical conductivity, which is further enhanced by the platinum coating and any additional conductive treatments.

3. Robust Structural Integrity. The sintered titanium backbone ensures that the GDL can withstand the compressive forces within the fuel cell stack without compromising its porosity or integrity.

4. Catalytic Efficiency. The platinum coating provides numerous active sites for the electrochemical reactions, leading to higher efficiency and lower activation losses in the fuel cell.

5. Heat Management. The metal base of the GDL also aids in dissipating heat generated during operation, helping to maintain a stable temperature within the cell.

6. Longevity. The durable nature of both titanium and platinum means that the GDL can maintain performance over extended periods of use, contributing to the overall lifespan of the fuel cell.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português