Product Details

Proton exchange membrane electrolyzer (PEM electrolyzer) is an important equipment in modern electrolysis technology, widely used in hydrogen production, fuel cell and other fields. In PEM electrolyzer, the anode gas diffusion layer (GDL) is one of the key components, and its performance directly affects the efficiency and stability of the electrolyzer. As a high-performance electrolytic material, high-density titanium felt is widely used in the anode GDL of PEM electrolyzer.

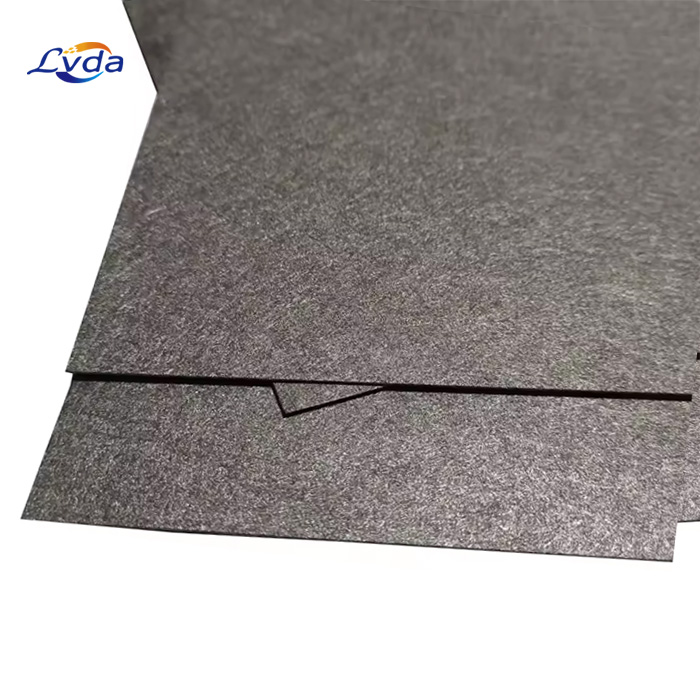

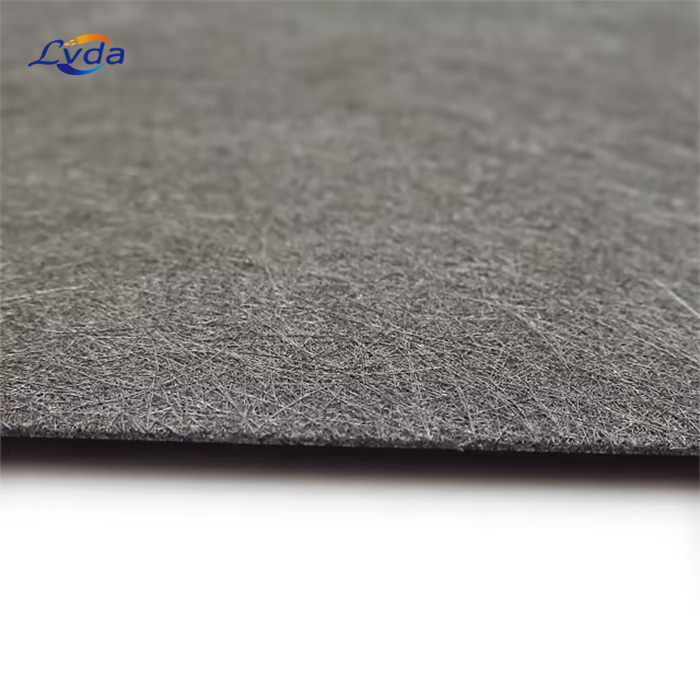

Characteristics of high density titanium felt

High-density titanium felt is a felt-like material made of high-purity titanium fibers through special processing. Its main characteristics are as follows:

1. High density. High-density titanium felt has a higher density, which makes it more stable and strong during electrolysis.

2. Corrosion resistance. Titanium is a natural corrosion-resistant metal that maintains excellent corrosion resistance in acidic environments. In PEM electrolyzers, high-density titanium felt can effectively resist the oxidation environment on the anode side, reducing equipment maintenance costs.

3. High strength. High-density titanium felt has excellent mechanical strength and can withstand high pressure and high temperature during electrolysis, thus enhancing the service life of the electrolytic cell.

4. Stability. High-density titanium felt has good stability during electrolysis, effectively preventing coating peeling and catalyst loss, ensuring long-term stable operation of the electrolyzer.

5. Ease of processing. High-density titanium felt has good machinability and can be cut, stamped, and formed according to the design requirements of the electrolyzer, reducing production costs.

6. Environmentally friendly. Titanium is an environmentally friendly metal and will not cause pollution to the environment. The use of high-density titanium felt as the substrate of the electrolyzer meets the requirements of environmental protection and sustainable development.

The advantages of high-density titanium felt

1. Improve the performance of the electrolytic cell. Using high-density titanium felt as the substrate of the electrolytic cell can improve the corrosion resistance, strength and stability of the electrolytic cell, thereby improving the performance of the electrolytic cell.

2. Extend service life. The excellent performance of high-density titanium felt can effectively extend the service life of the electrolyzer and reduce the maintenance cost of the equipment.

3. Reduce production costs. High-density titanium felt has good workability and can be processed according to the design requirements of the electrolyzer, reducing production costs.

4. Environmental protection and sustainable development. Titanium is an environmentally friendly metal, and high-density titanium felt is used as the substrate of the electrolyzer, which meets the requirements of environmental protection and sustainable development.

Application in PEM Electrolyzer

In PEM cells, high-density titanium felt is mainly used as the substrate for the anode gas diffusion layer (GDL). Due to its high density characteristics, high-density titanium felt can provide better structural stability and strength, thus ensuring stable performance and long life during operation of the cell.

In addition, high-density titanium felt has good corrosion resistance and stability during electrolysis, which can effectively resist the oxidation environment on the anode side and reduce the maintenance cost of the equipment. This makes high-density titanium felt an ideal material for anode GDL in PEM electrolyzers.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português