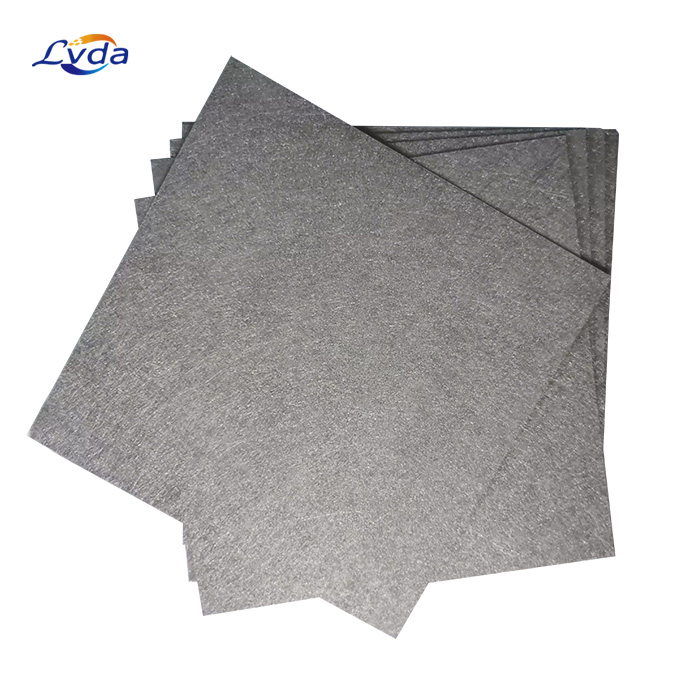

Product Details

The growing demand for clean and sustainable energy sources has led to an increased interest in hydrogen production by water electrolysis. This process involves the decomposition of water into hydrogen and oxygen through the use of an electrical current. The efficiency and effectiveness of this method rely heavily on the performance of the electrodes and the electrolyte used in the process. One material that has gained significant attention in recent years is the sintered titanium felt.

Sintered titanium felt is a type of porous metal material made from titanium fibers. The manufacturing process involves the pressing and sintering of titanium fibers to create a highly porous structure with excellent permeability. The resulting material has a high surface area, excellent corrosion resistance, and outstanding thermal conductivity, making it an ideal choice for various applications, including water electrolysis.

Parameters

Material : Titanium

Shape : Round, square

Porosity : 50% - 80%

Thickness : 0.25mm, 0.4mm, 0.6mm, 0.8mm, 1mm

Place of Origin : Henan, China

Condition : New

***Customized service is available.

Properties of good permeability sintered titanium felt for hydrogen production by water electrolysis

1. High porosity and permeability. Sintered titanium felt has a high porosity rate, typically ranging from 50% to 80%, depending on the manufacturing process. This high porosity results in excellent permeability, allowing for efficient gas and liquid transport during the electrolysis process.

2. High surface area. The sintered titanium felt has a large surface area, which is essential for enhancing the electrochemical reactions during water electrolysis. The high surface area provides more active sites for the reactions to occur, leading to improved hydrogen production efficiency.

3. Excellent corrosion resistance. Titanium is known for its outstanding corrosion resistance, making it an ideal material for use in electrolysis applications. The sintered titanium felt maintains this property, ensuring long-term stability and durability in corrosive environments.

4. Good thermal conductivity. Despite its porous structure, sintered titanium felt exhibits good thermal conductivity, ensuring efficient heat transfer during the electrolysis process. This property helps maintain a stable operating temperature, which is crucial for optimizing the efficiency and performance of the electrolysis system.

Applications in Hydrogen Production by Water Electrolysis

Sintered titanium felt can be used as an electrode material in water electrolysis systems. Its high permeability and surface area make it an excellent choice for both the anode and cathode electrodes. The following are some of the key benefits of using sintered titanium felt in hydrogen production by water electrolysis:

1. Enhanced electrochemical performance. The high surface area and porosity of sintered titanium felt result in improved electrochemical performance. This improvement leads to increased hydrogen production efficiency and reduced energy consumption.

2. Stable operation. The excellent corrosion resistance and thermal conductivity of sintered titanium felt ensure stable operation under harsh electrolysis conditions. This stability reduces the risk of equipment failure and extends the service life of the electrolysis system.

3. Cost-effective. Although sintered titanium felt may have a higher initial cost compared to other electrode materials, its superior performance and durability can lead to reduced operational and maintenance costs in the long run. This cost-effectiveness makes it an attractive option for large-scale hydrogen production by water electrolysis.

4. Environmental benefits. The use of sintered titanium felt in hydrogen production by water electrolysis contributes to a cleaner and more sustainable energy source. Hydrogen can be used in fuel cells to generate electricity with water as the only byproduct, making it an environmentally friendly alternative to traditional fossil fuels.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português