Product Details

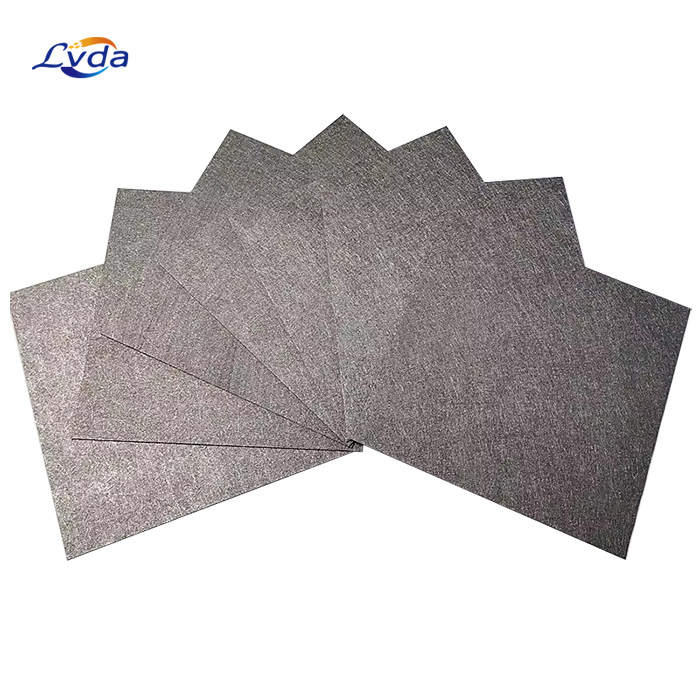

Corrosion-resistant sintered titanium fiber felt is a high-performance material that is widely used in the filtration industry. Made from sintered titanium fibers, this felt offers unparalleled corrosion resistance and can withstand harsh chemical environments and high temperatures.

Parameters

Thickness : 0.2mm, 0.25mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1mm or customized

Porosity : 50% 55% 60% 65% 70% 75% 80%

Ti Content (%) : More than 99%

Size : Customized, max 800×800

Features

The main features and applications of corrosion-resistant sintered titanium fiber felt for the filtration industry are as follows:

1. Corrosion resistance. Corrosion-resistant sintered titanium fiber felt exhibits excellent resistance to corrosion caused by acids, alkalis, organic solutions, and chemical medicines. This property makes it suitable for use in harsh environments and chemical processing applications.

2. High temperature resistance. The material can withstand long-term working temperatures of up to 480°C, making it suitable for use in high-temperature filtration applications.

3. Enhanced gel removal. The addition of metal fiber felt enhances the gel removal property of sintered filter media and eliminates fiber breaks during spinning. This feature results in more effective and high-quality filtration.

4. Durability. Corrosion-resistant sintered titanium fiber felt is highly durable, ensuring a long-lasting and continuous task performance with no breakages. This property makes it ideal for use in critical filtration applications where downtime for repairs or replacements is not an option.

5. Versatility. The material can separate both the finest and largest components due to its versatile nature. This property makes it suitable for use in a wide range of filtration applications.

6. Easy to machine, mold, and weld. Corrosion-resistant sintered titanium fiber felt is easy to machine, mold, and weld, making it simple to customize for specific filtration applications.

Application

In the filtration industry, the corrosion-resistant sintered titanium fiber felt has several key applications:

1. Chemical processing. It is widely used for filtering strong acids, alkalis, salts, and other corrosive solutions. This includes applications in processes such as chemical synthesis, electroplating baths, catalysts support, and purification of various chemicals.

2. Petrochemical industry. In oil refining and petrochemical production, it serves as an efficient filter media or catalyst carrier for the precise filtration of crude oil, refined oil products, and petrochemical substances.

3. Environmental protection. It is employed in wastewater treatment to remove heavy metal ions and other harmful substances. It also finds application in air pollution control systems where it filters out particulate matter and hazardous gases.

4. Nuclear industry. Due to its excellent radiation resistance, it can be utilized for filtering radioactive liquids or gases in nuclear power plants.

5. Food & pharmaceutical industries. It's suitable for sterile filtration in food and beverage processing and pharmaceutical manufacturing where it helps in removing impurities, bacteria, and turbidity from liquids.

6. Water treatment. In seawater desalination and deep purification of drinking water, it's used both for pre-filtration tasks and as a protective filter before reverse osmosis or ultrafiltration membranes.

7. Other applications. It is also found in the metallurgical, energy, fine chemical, and electronics industries for the filtration of high-temperature gases and liquids, especially in situations where exceptional corrosion resistance and thermal stability are required.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português