Product Details

The high porosity platinized titanium fiber felt for fuel cell specifically designed for Proton Exchange Membrane Fuel Cells (PEMFC). In PEMFC, this type of felt plays a crucial role as an electrode material, typically serving as the anode material (fuel gas side).

Parameters

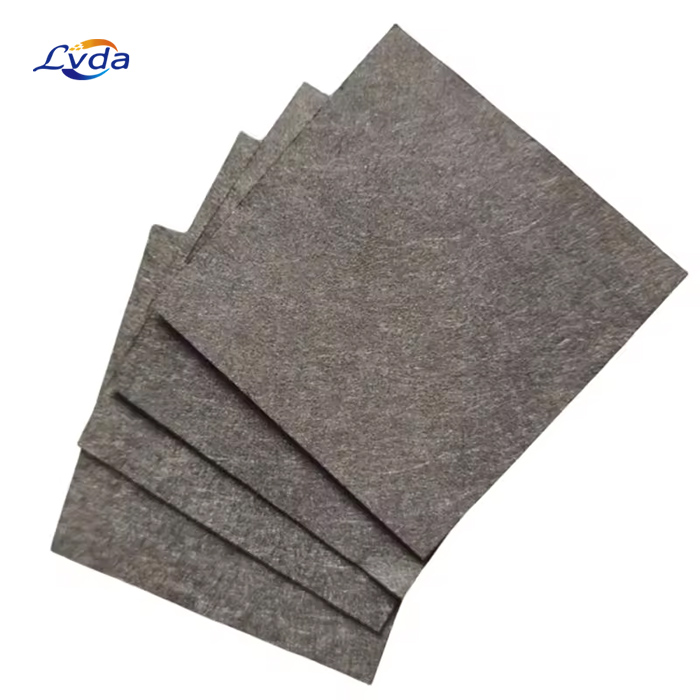

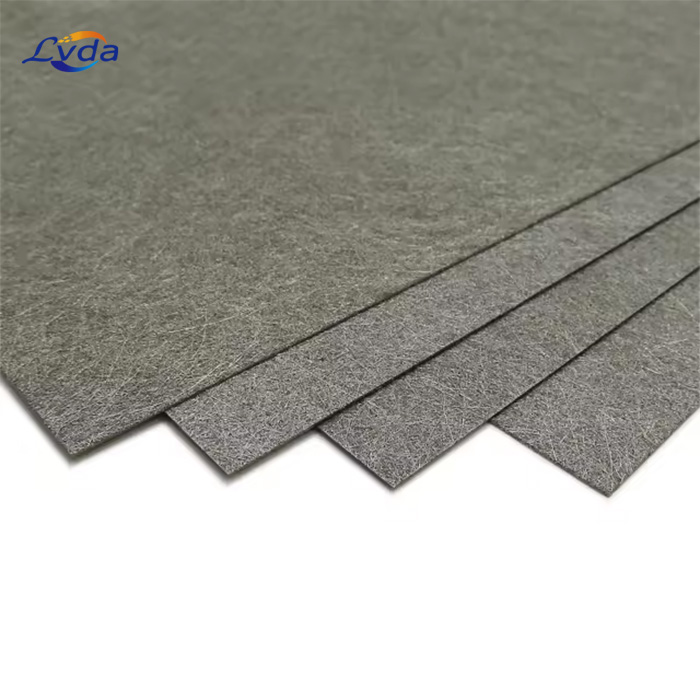

Color : Light gray

Dimension : Customized (100*100mm, 200*200mm, 300*300mm, and customized sizes)

Thickness : 0.25mm - 1mm (common thicknesses: 0.25mm, 0.4mm, 0.6mm, 0.8mm)

Porosity : 60% - 70%

Structure and Features

The high porosity platinized titanium fiber felt is composite materials made from titanium fibers with a platinum catalyst coating. Platinum is widely used in fuel cells due to its excellent electrochemical stability and catalytic activity, which facilitate the breakdown of hydrogen gas and the reduction of oxygen gas on the electrode surface.

1. High porosity. This is particularly important for enhancing cell performance as it allows for better gas transport and liquid diffusion, reducing the resistance of the liquid film and enabling more effective delivery of fuel and oxidant to the catalyst surface.

2. Titanium fiber. Titanium fibers offer good chemical stability, corrosion resistance, and mechanical strength, allowing them to withstand the various conditions encountered during fuel cell operation.

3. Platinum coating. The platinum layer increases the active surface area of the electrode and provides more catalytic reaction sites, thereby improving the efficiency of electrochemical reactions.

Functions and Applications

The primary functions of the high porosity platinized titanium fiber felt for fuel cells includes:

1. Catalytic reaction. The platinum catalyst efficiently catalyzes the electrochemical reactions of hydrogen and oxygen gases.

2. Gas diffusion. The porous structure allows gases to diffuse within the electrode, contacting the catalyst surface for reaction.

3. Proton transport. On the negative electrode side, there is a need for a proton exchange membrane to facilitate proton transport, and the titanium fiber mat should provide channels for protons and have good contact with the proton exchange membrane.

4. Mechanical support. It also needs to provide mechanical support during the assembly of the fuel cell.

Manufacturing Process

The manufacturing process for the high porosity platinized titanium fiber felt is complex, involving steps such as fiber preparation, platinum deposition, and the formation of pore structures. Typically, titanium fibers are produced through methods like melt spinning or solution spinning, followed by the deposition of platinum onto the fibers’ surface using techniques such as chemical vapor deposition (CVD) or physical vapor deposition (PVD). Finally, specific post-processing techniques are employed to create a high-porosity structure.

Development Trends

With the advancement of new energy technologies, the high porosity platinized titanium fiber felt for fuel cells are continuously improving in terms of material performance, manufacturing processes, and cost control. Researchers are working on the development of electrode materials with higher performance, longer durability, and lower costs to promote the wide application of fuel cells in areas such as new energy vehicles, portable power sources, and stationary power sources.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português