Product Details

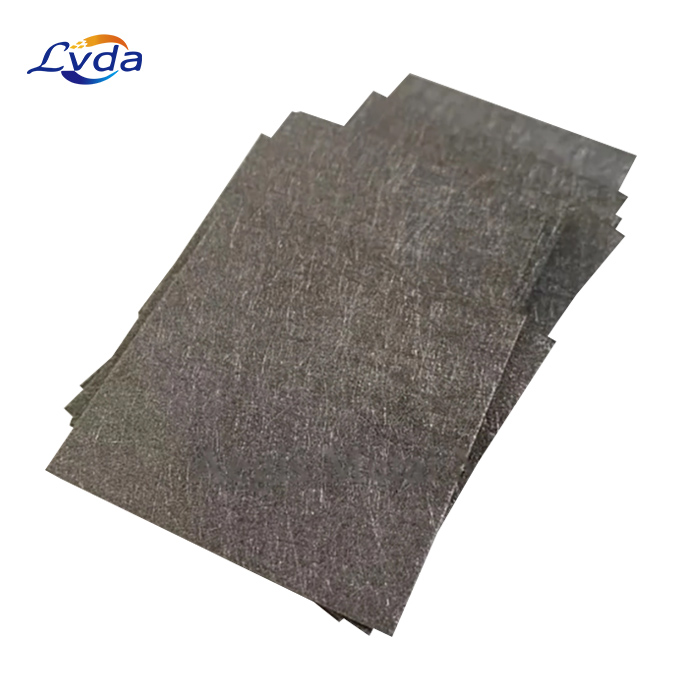

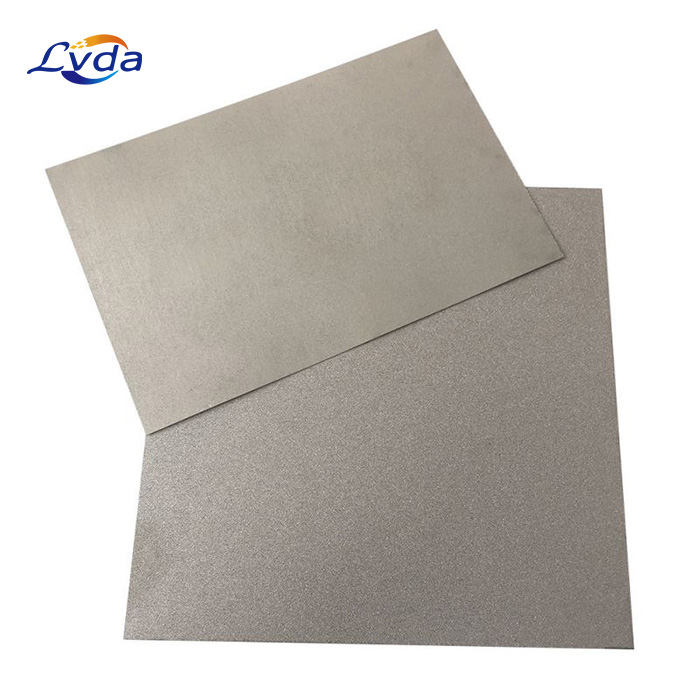

Titanium fiber felt is commonly used as the gas diffusion layer or anode porous transport layer in the process of hydrogen production through water electrolysis. Titanium fiber felt features a three-dimensional network porous structure, corrosion resistance, high current density, good water permeability, long lifespan, and excellent heat dissipation performance. These characteristics make it highly suitable for applications such as water electrolysis for hydrogen production.

Advantages

The advantages of titanium fiber felt in water electrolysis hydrogen production are mainly reflected in the following aspects:

1. Good electrical conductivity. Titanium fiber felt has high electrical conductivity, which is conducive to reducing power loss during electrolysis and improving electrolysis efficiency.

2. Chemical stability. Titanium materials have excellent chemical stability and can resist various corrosive substances generated during the electrolysis of water to produce hydrogen, thus enhancing the lifespan and stability of the equipment.

3. High porosity. Titanium fiber felt has high porosity, which is conducive to the diffusion of gas and liquid, improving gas transmission efficiency and reducing energy consumption during electrolysis.

4. Mechanical strength. Titanium fiber felt has a certain degree of mechanical strength and can be used as a support material for electrodes, providing mechanical support for electrode catalysts and improving the stability and lifespan of equipment.

5. Customized processing: Titanium fiber felt can be customized according to actual needs to meet the performance requirements of different electrolytic water hydrogen production equipment.

6. Reusable. Titanium fiber felt has good durability in the process of electrolysis of water to produce hydrogen, and can be reused to reduce the operating cost of the equipment.

Durability of titanium fiber felt in water electrolysis hydrogen production

Titanium fiber felt has good durability in water electrolysis hydrogen production. This is mainly due to the excellent chemical stability and corrosion resistance of titanium materials. In the process of electrolytic water hydrogen production, titanium fiber felt can resist the erosion of various corrosive substances and maintain stable performance. The durability of titanium fiber felt in water electrolysis hydrogen production is mainly reflected in the following aspects:

1. Good chemical stability. Titanium materials have excellent chemical stability and can resist various corrosive substances generated during the electrolysis of water to produce hydrogen, such as oxygen, hydrogen, and acidic or alkaline electrolytes.

2. High temperature stability. Titanium fiber felt is treated at high temperature and has high structural stability. During the electrolysis process, its performance remains stable even under high temperature conditions.

3. Mechanical strength. Titanium fiber felt has a certain mechanical strength and can withstand various stresses generated during electrolysis, preventing structural deformation or damage.

4. Oxidation resistance. Titanium fiber felt has good oxidation resistance and can effectively resist the erosion of oxidant substances under high temperature and high pressure conditions, prolonging the service life of the equipment.

Application

Electrolysis of water for hydrogen is achieved by decomposing water into hydrogen and oxygen through an electrolysis process. Titanium fiber felt plays a key role in this process, with the following main applications:

1. Anode material. In the electrolysis of water for hydrogen, titanium fiber felt is used as the anode material. It has excellent electrical conductivity and chemical stability, allowing it to resist the oxidation substances generated during the electrolysis process, thereby improving the electrolysis efficiency and the service life of the equipment.

2. Gas diffusion layer. Titanium fiber felt can be used as the gas diffusion layer in the electrolytic cell, promoting the diffusion of the generated hydrogen and oxygen in the electrolyte, improving the gas transmission efficiency, and reducing the energy consumption during the electrolysis process.

3. Catalyst carrier. Titanium fiber felt can be used as a catalyst carrier, increasing the utilization and stability of the catalyst. During the electrolysis process, the catalyst can reduce the overpotential of the electrode reaction, improving the electrolysis efficiency.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português