Product Details

Titanium sintered fiber felt is a material that is often used in fuel cell research due to its unique properties. It is a crucial component in fuel cell technology, particularly in proton exchange membrane fuel cells (PEMFCs) and solid oxide fuel cells (SOFCs). The properties of the felt, such as thickness, size, porosity, and customizability, play a significant role in the performance and efficiency of the fuel cell.

Customizable thickness and size - The thickness and size of the titanium sintered fiber felt can be customized according to the specific requirements of the fuel cell design. This allows for optimal performance and efficiency, as the thickness and size can be tailored to fit the desired application.

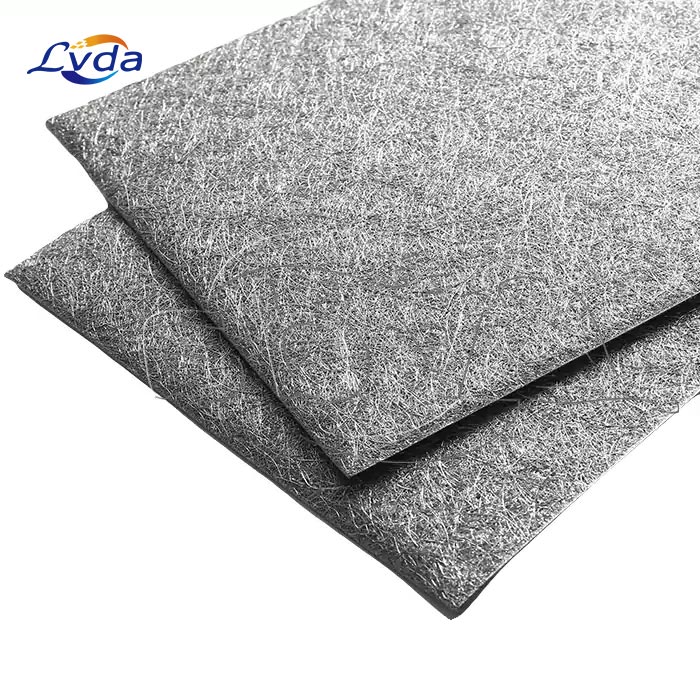

Porosity - The porosity of the felt is another critical factor that affects fuel cell performance. Higher porosity results in increased gas diffusion and improved electrochemical reactions, leading to higher fuel cell efficiency. However, excessive porosity can also lead to increased electrical resistance and decreased mechanical strength. Therefore, it is essential to strike a balance between porosity and other properties for optimal fuel cell performance.

Titanium as a material - Titanium is an ideal material for sintered fiber felts due to its excellent corrosion resistance, high temperature stability, and good electrical conductivity. These properties make titanium felts suitable for use in various fuel cell types and operating conditions.

Features

1. Porous structure. High porosity allows for effective gas diffusion, a critical function in Proton Exchange Membrane Fuel Cells (PEMFCs) where hydrogen and oxygen need to diffuse through the Gas Diffusion Layer (GDL) to reach the catalyst layer.

2. Uniformity. The sintering process bonds the fibers together while maintaining the uniform distribution of pores, ensuring consistent gas flow and electrical conductivity throughout the material.

3. Mechanical strength. Despite its porous nature, titanium sintered fiber felt provides adequate mechanical strength and durability under operating conditions, including temperature cycling and pressure fluctuations.

4. Corrosion resistance. Titanium's inherent corrosion resistance makes it particularly suitable for use in the acidic environment found in PEMFCs.

Parameters

Thickness : 0.2mm-2mm

Porosity : 60-70%

Color : Light gray

Dimension : As for customer's request

Place of origin : Henan, China

Applications in fuel cell research

Titanium sintered fiber felt is widely used in fuel cell research. This material is made from titanium fibers through a high-temperature sintering process, forming a three-dimensional network structure with high porosity, good electrical conductivity, and chemical stability. Here are some specific applications of titanium sintered fiber felt in fuel cell research:

1. Gas Diffusion Layer (GDL). Titanium sintered fiber felt can be used as the gas diffusion layer in the fuel cell stack. As the GDL, it provides diffusion channels for fuel gases and oxidizing agents, ensuring uniform distribution and access to the catalyst layer.

2. Electrode support. Titanium sintered fiber felt can serve as a support structure for the catalyst layer, providing mechanical strength and preventing catalyst particles from falling off during operation, thus improving the stability and lifespan of the fuel cell.

3. Electrical conductor. With good electrical conductivity, titanium sintered fiber felt can serve as a pathway for electrons between the anode and cathode, enhancing the power output of the fuel cell.

4. Moisture management. During operation, fuel cells generate water, and titanium sintered fiber felt can adsorb and remove this water, maintaining humidity balance within the stack and preventing the suppression of electrochemical reactions.

5. Corrosion resistance. Titanium materials exhibit excellent chemical stability, resisting various corrosive substances within the fuel cell, thus prolonging the lifespan of the fuel cell.

In summary, titanium sintered fiber felt has extensive applications in fuel cell research, serving as a gas diffusion layer, electrode support, electrical conductor, and more. Additionally, it exhibits excellent moisture management and corrosion resistance, making it significantly important for fuel cell research.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português