Product Details

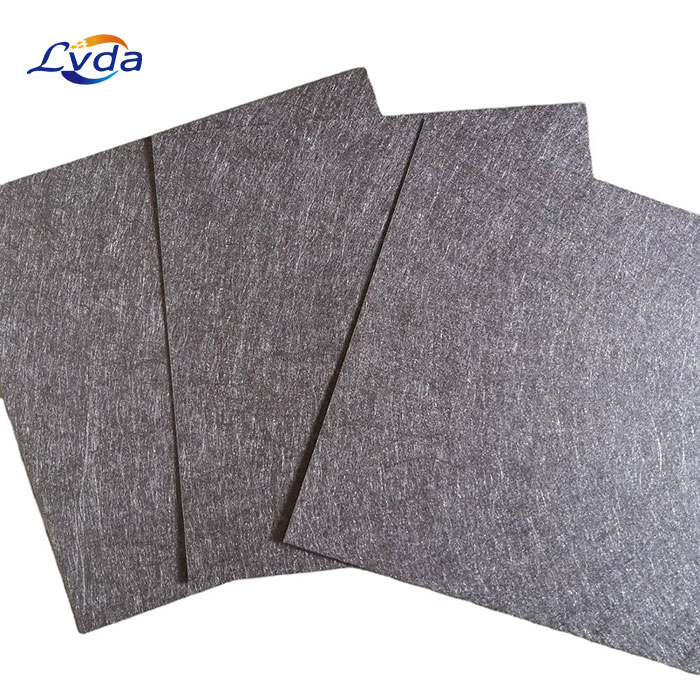

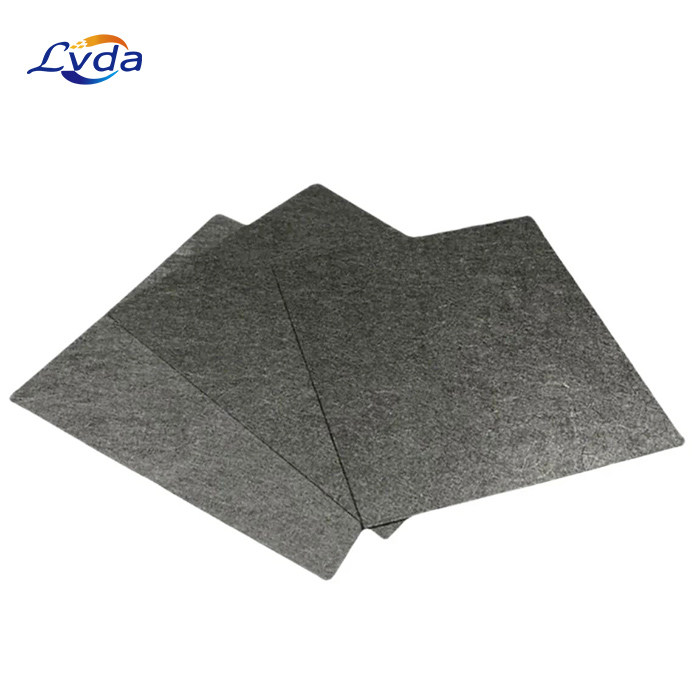

Titanium fiber felt is a high-performance material with a three-dimensional mesh porous structure, exhibiting superior performance in many industrial applications. This unique product is made from a combination of high-quality titanium fibers, which are woven together to create a strong and durable mesh structure.

The top-quality three-dimensional mesh porous structure titanium fiber felt boasts exceptional strength and durability. The titanium fibers used in its construction are known for their high tensile strength and resistance to corrosion, making them an ideal choice for use in harsh or demanding environments. Additionally, the mesh structure of the material provides added strength and stability, ensuring that it can withstand even the most intense pressures and temperatures.

This material can provide excellent fluid flow properties. The unique three-dimensional structure of the mesh titanium fiber felt allows for efficient fluid movement through the material, reducing the risk of clogging or blockages. This makes it an ideal choice for use in filtration systems, where it can help to remove impurities and contaminants from fluid streams, ensuring that they remain clean and pure.

In addition to its fluid flow properties, the top-quality three-dimensional mesh titanium fiber felt also offers excellent filtration capabilities. The small pore size of the material ensures that even the smallest particles are captured and removed from fluid streams, helping to maintain the purity and quality of the fluid. This makes it an ideal choice for use in a variety of different industries, including food and beverage production, pharmaceutical manufacturing, and even water treatment facilities.

Structural Features

It possesses an excellent three-dimensional mesh porous structure, which endows titanium fiber felt with high porosity and a large specific surface area.

The pore size distribution is uniform, contributing to efficient mass transfer in filtration and other applications.

The thickness of titanium fiber felt can range from 0.2mm to 1mm, with porosity between 60-70%, and fiber diameters around 30-60 microns.

Physical and Chemical Properties

It has strong corrosion resistance, allowing titanium fiber felt to be used in various harsh environments without deterioration.

Good water permeability and heat dissipation make it beneficial for applications requiring cooling or liquid filtration.

High current density and low voltage, stable performance, and long lifespan, making it suitable for use in batteries or other electrochemical devices.

Application Range

In the field of fuel cell gas diffusion layers, titanium fiber felt can serve as a substitute for carbon fiber due to its non-corrosive nature.

Used in water electrolysis for hydrogen production, PEM electrolyzer diffusion layers, and hydrogen fuel-related equipment.

Applied in hydrogen absorbers, hydrogen-rich drinking machines, hydrogen-rich cups, and other products.

As a filter element, titanium fiber felt can be used in various filtration systems, such as metal fiber felt filters and melt filtration elements.

Manufacturing Process

Titanium fiber felt is made by non-woven laying, sintering, and cutting of titanium fibers.

To improve its electrical conductivity, it is usually necessary to plate noble metals such as platinum or iridium on the surface.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português