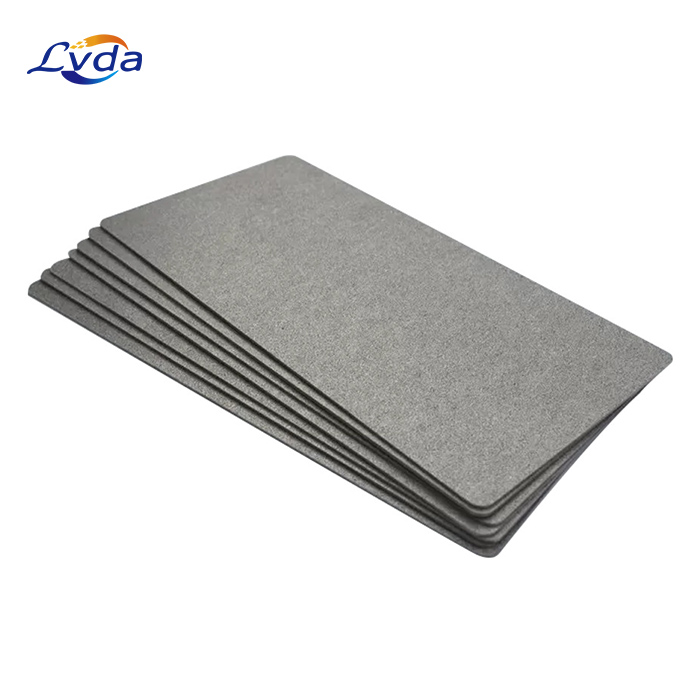

Product Details

The platinum-coated sintered titanium felt is a specialized material designed specifically for the gas diffusion layer of Proton Exchange Membrane Fuel Cells (PEMFCs). This material not only inherits the excellent characteristics of sintered titanium felt, such as high porosity, good corrosion resistance, and superior mechanical properties, but also enhances its performance in PEMFCs through platinum coating.

Parameters

Material : Ti

Thickness : 0.25mm - 3.0mm

Porosity : 70% - 85%

Technique : Vacuum sintering

Brand Name : LVDA

Place of Origin : Henan, China

Properties

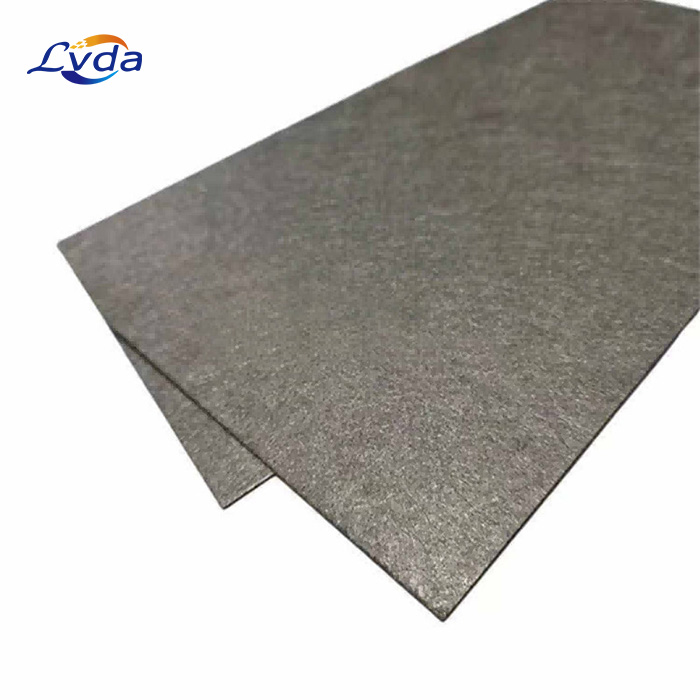

1. High Porosity and Good Breathability

The platinum-coated sintered titanium felt boasts a porosity of 70%-85%, providing excellent breathability and water drainage capabilities. In PEMFCs, the high-porosity gas diffusion layer ensures smooth access of reactant gases (such as hydrogen and oxygen) to the catalyst layer, maintaining efficient electrochemical reactions.

2. Excellent Corrosion Resistance

Titanium, being a chemically stable metal, resists various forms of chemical corrosion. Therefore, the platinum-coated sintered titanium felt exhibits exceptional stability in the working environment of PEMFCs, such as acidic electrolytes, effectively prolonging the service life of the fuel cell.

3. Superb Mechanical Properties

The high strength and toughness of titanium fibers endow the platinum-coated sintered titanium felt with excellent mechanical properties. It can withstand the stresses and strains encountered during PEMFC operation, maintaining structural integrity.

4. Good Conductivity

The platinum coating not only enhances the corrosion resistance of the titanium fiber felt but also confers good conductivity. Platinum, a highly conductive noble metal, efficiently transmits the current generated in PEMFCs.

5. Balanced Hydrophilicity and Hydrophobicity

By controlling the surface properties of the platinum-coated sintered titanium fiber felt, a balance can be achieved between hydrophilicity and hydrophobicity. This facilitates effective transport of water and reactant gases in PEMFCs, preventing issues such as "water flooding" or "dry-out" phenomena.

Applications

The platinum-coated sintered titanium felt is primarily used as a raw material for the gas diffusion layer in PEMFCs. In PEMFCs, the gas diffusion layer is positioned between the catalyst layer and the bipolar plate, serving functions such as supporting the catalyst, transporting reactant gases, and removing generated water. The high porosity, good corrosion resistance, excellent mechanical properties, and conductivity of the platinum-coated sintered titanium felt provide a stable and efficient working environment for PEMFCs.

Advantages

1. High Performance

The platinum-coated sintered titanium felt combines the advantages of sintered titanium fiber felt and platinum, offering a high-performance solution for the gas diffusion layer in PEMFCs.

2. Longevity

Due to its excellent corrosion resistance, the platinum-coated sintered titanium felt maintains the stable operation of PEMFCs over extended periods, reducing maintenance costs and the frequency of replacements.

3. Wide Application Prospects

As PEMFCs gain increasing applications in various sectors such as transportation, energy, and military, the demand for platinum-coated sintered titanium felt is also growing steadily.

In summary, the platinum-coated sintered titanium felt, as an advanced raw material for the gas diffusion layer, offers high performance, longevity, and vast application potential, strongly supporting the commercialization of PEMFCs. With the continuous development and popularization of PEMFC technology, the application of platinum-coated sintered titanium felt is expected to expand even further.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português