Product Details

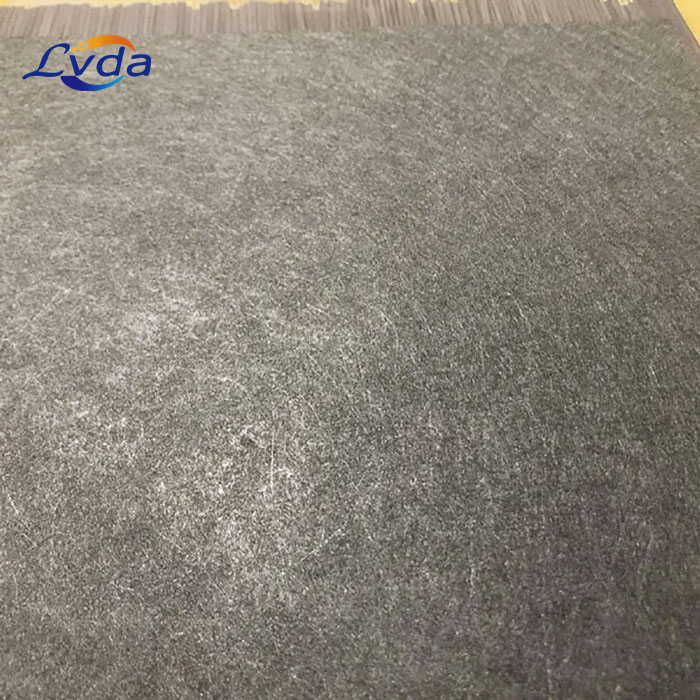

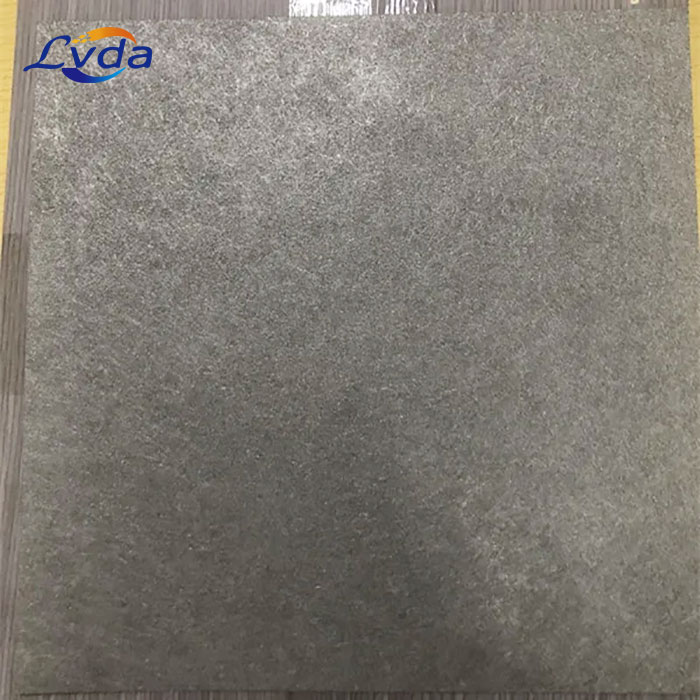

Titanium fiber felt for hydrogen absorber is a diffusion layer material, provides electrons between the catalyst layer and the bipolar plate or the current distributor on the anode side. Due to its three-dimensional network porous structure, high corrosion resistance, high porosity, and other characteristics, titanium felt has become one of the best materials of diffusion layer in fuel cell and hydrogen production by water electrolysis.

Parameter

Material : Titanium

Thickness : 0.25mm, 0.4mm, 0.6mm, 0.8mm

Porosity : 60%-78%

Size : 500*500mm

Shape : Square (other shape can be customized)

MOQ : Flexible

Titanium fiber felt is a three-dimensional network porosity material made from micro-scale pure titanium fibers. It features high porosity, high strength, low density, and excellent corrosion resistance. In the field of hydrogen absorption, titanium fiber felt can be used as a diffusion layer material in devices such as hydrogen generators and fuel cells.

The application of titanium fiber felt in the field of hydrogen absorption is mainly reflected in the following aspects:

1. Hydrogen generator. In the process of water electrolysis for hydrogen production, titanium fiber felt can be used as a diffusion layer to help hydrogen diffuse from the reaction area to the outlet. Since titanium fiber felt has high porosity and good permeability, it can effectively reduce the resistance of hydrogen diffusion, thereby improving the efficiency of hydrogen production.

2. Fuel cell. Titanium fiber felt can be used as a bipolar plate or anode-side current distributor in fuel cells. Its three-dimensional network porosity structure provides good support for the catalyst layer, improving the performance and service life of fuel cells.

3. Hydrogen purification. Titanium fiber felt can be used for hydrogen filtration and purification processes, removing particles and harmful impurities in hydrogen. This can improve the purity of hydrogen, reducing wear and failure rates of fuel cells and other equipment.

The advantages of titanium fiber felt in the field of hydrogen absorption are as follows:

1. High Porosity: The porosity of titanium fiber felt can reach over 80%, providing good permeability and filtration effects. The high porosity allows titanium fiber felt to have low resistance during hydrogen diffusion, improving the efficiency of hydrogen production.

2. Excellent Corrosion Resistance: Titanium fiber felt has excellent corrosion resistance and can work stably in harsh environments such as acids and alkalis for a long time. This makes it suitable for applications in hydrogen generators, fuel cells, and other devices.

3. High Strength: Titanium fiber felt has high strength and can withstand high pressure and temperature. This makes it suitable for use in high-temperature and high-pressure environments such as aerospace and chemical industries.

4. Low Density: Titanium fiber felt has a low density, offering good lightweight properties. This makes it promising for applications in aerospace and other fields.

In conclusion, titanium fiber felt has good application prospects in the field of hydrogen absorption and is expected to provide strong support for the development of hydrogen energy technology.

Application

Diffusion layer of hydrogen cell stack.

Hydrogen-rich water dispenser.

PEM hydrogen production by water electrolysis.

Hydrogen absorber.

Liquid or gas diffusion layer.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português