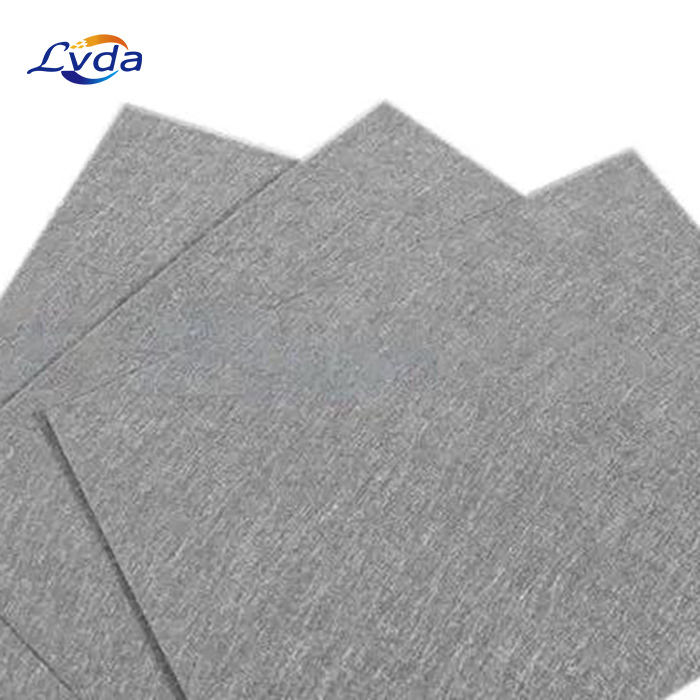

Product Details

The liquid/gas diffusion layer (LGDL) used in proton exchange membrane (PEM) fuel cells is one of the key components. In PEM fuel cells, the main role of the LGDL is to ensure that hydrogen and oxygen can be uniformly and efficiently transported to the catalyst layer, and it is also responsible for removing the generated water molecules from the catalytic layer, preventing the accumulation of water from affecting the battery performance.

Titanium fiber felt is widely adopted as the material of choice for LGDL due to its unique performance advantages.

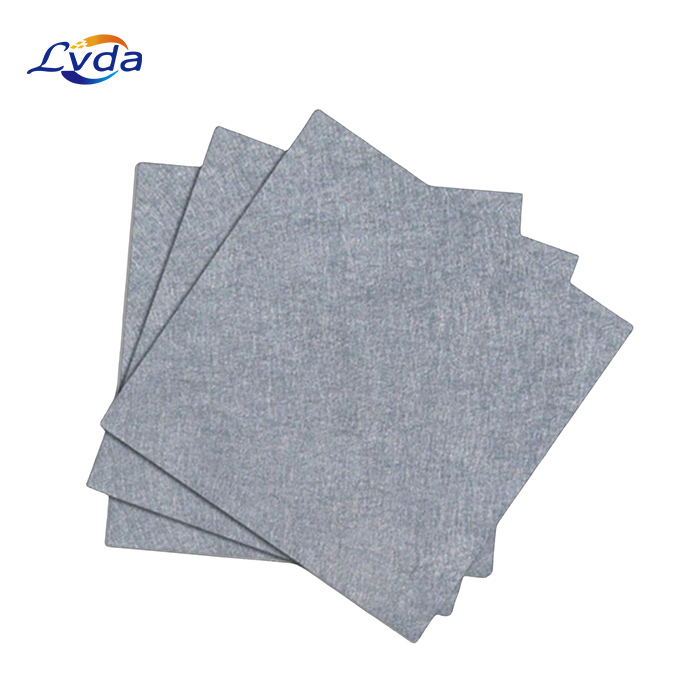

1. High surface area. The three-dimensional network structure of titanium fiber mat provides a large surface area, which helps to improve the gas transmission efficiency and reaction surface area, thereby enhancing the overall performance of the fuel cell.

2. Good electrical conductivity. Titanium fibers have good electrical conductivity, which is essential for the transmission of electrons inside the fuel cell. Good electrical conductivity helps reduce energy loss and improve the power output of the battery.

3. Chemical stability. Titanium fiber exhibits excellent stability to most chemicals, especially in acidic environments, making it an ideal material for PEM fuel cells.

4. Mechanical stability. Titanium fiber mat has good mechanical strength and flexibility, capable of withstanding mechanical stress and deformation that may occur during fuel cell operation.

5. Thermal stability. Titanium fiber felt can maintain a stable structure and performance in high-temperature environments, which is particularly important for high-temperature PEM fuel cells.

6. Corrosion resistance. Titanium fibers are highly resistant to corrosive substances that may appear in fuel cells, prolonging the service life of fuel cells.

In practical applications, titanium fiber felt as an LGDL material can effectively solve key challenges such as uneven gas transmission, water management issues, and stability of the catalyst layer, thus improving the overall efficiency and reliability of PEM fuel cells.

Parameters

Material : Titanium

Size : ≤1500*1200mm

Fiber size : 20 micron - 40 micron

Thickness : 0.20mm, 0.25mm, 0.40mm, 0.60mm

Porosity : 60% - 75%

※ Porosity and size can be customized.

Manufacturing Process for Titanium Felt

Preparation of Titanium Fibers - High-quality titanium fibers are prepared, which are typically a few micrometers in diameter.

Blending - The fibers are blended with a binder and possibly other additives to enhance the properties of the final product.

Forming - The blended mixture is formed into a mat or felt-like structure.

Sintering - The formed material is then heated to high temperatures in a sintering process that fuses the fibers together without melting them. This creates a porous structure with interconnected pores.

Post-treatment - The sintered felt may undergo additional treatments such as surface modification or coating to enhance its performance for specific applications.

Features

Three-dimensional grid porous structure and Strong corrosion resistance

Optimal electrolysis performance or Uniform pore size distribution

High porosity and current density

Application

Titanium felt for Liquid/ Gas diffusion layer (LGDL)

Hydrogen absorber and Hydrogen-rich water dispenser

Diffusion layer of hydrogen fuel cell stack

Hydrogen production by PEM water electrolysis

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português