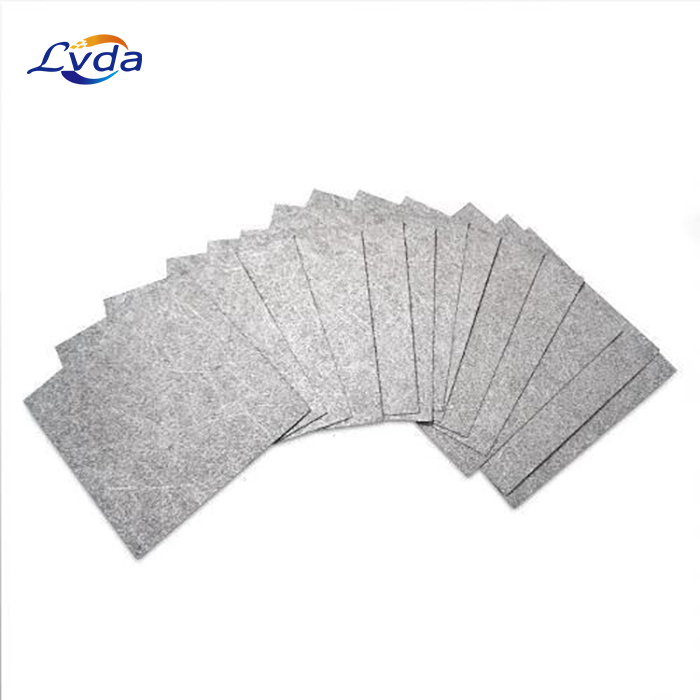

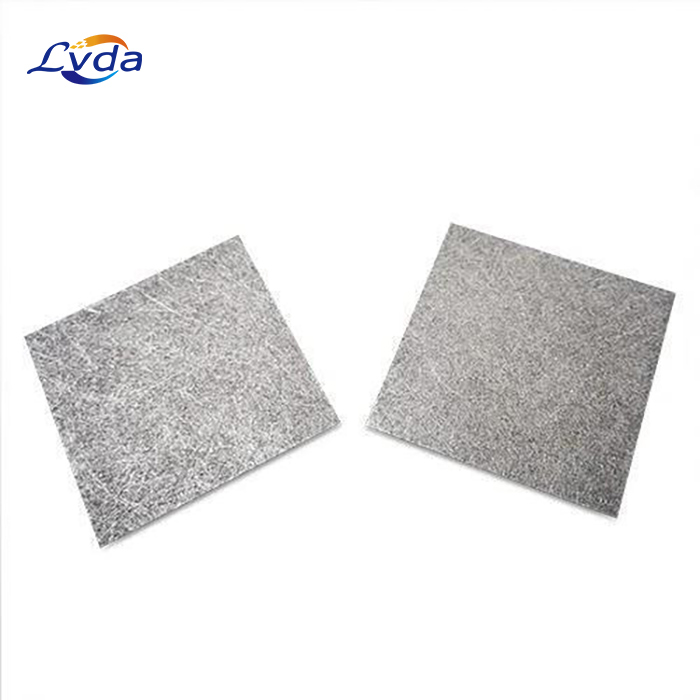

Product Details

High porosity micro titanium fiber sintered felt for filtration is a specialized material designed for applications where high efficiency and durability are required. This material is particularly well-suited for filtration processes in industries such as aerospace, automotive, healthcare, and environmental protection. Here’s a detailed introduction to its properties and how it is used in filtration:

Properties

1. High Porosity. The micro titanium fiber sintered felt has a porosity that can reach up to 60% or more. This allows for a greater surface area available for particle capture and improved airflow.

2. Micro Titanium Fibers. The fibers are extremely fine, which means the felt has a high specific surface area. This property enhances its adsorption capabilities and provides a larger area for capturing particles.

3. High mechanical strength. The sintered felt maintains high tensile and compressive strengths, even after the binder is burned out during the sintering process. This ensures that the filter material will withstand the forces exerted during filtration without deforming or breaking.

4. Resistance to chemical and thermal stress. Titanium has excellent resistance to chemicals, including acids and bases, as well as high temperatures. This makes the material suitable for filtration processes where exposure to aggressive media or high temperatures is a concern.

5. Electrostatic attraction. The micro titanium fibers can be charged during the manufacturing process, which can enhance the capture of particles by electrostatic attraction.

6. Customizable pore structure. The pore structure of the sintered felt can be customized to meet specific filtration requirements. This includes controlling the pore size, pore shape, and distribution, which affects the filtration efficiency and pressure drop.

Parameter

Porosity : 60-80%

Thickness : 0.2-0.4mm

Size : 1500*1200mm (customized according to customer needs)

Material : Titanium

Origin : Xinxiang, Henan, china

Filtration Applications

1. Gas Filtration. The high porosity and excellent mechanical properties of the micro titanium fiber sintered felt make it suitable for gas filtration applications, such as in air intake systems, HVAC systems, and chemical processing plants.

2. Liquid Filtration. The material can be used in liquid filtration processes, including oil and hydraulic fluids, water treatment, and pharmaceutical manufacturing, where particle removal is critical.

3. Solid Particle Filtration. In industries where solid particles need to be separated from gases or liquids, such as in the pharmaceutical, food, and powder handling industries, the micro titanium fiber sintered felt provides an efficient solution.

4. BioMedical Filtration. The biocompatibility of titanium and its resistance to biological fluids make the material suitable for medical filters, including blood filters and呼吸器 filters.

5. High-Temperature Filtration. The ability of titanium to withstand high temperatures makes the material suitable for filtration in applications such as aerospace engines and industrial furnaces.

The high porosity micro titanium fiber sintered felt for filtration is a versatile and durable material that offers both efficiency and longevity in a wide range of filtration applications. Its unique combination of properties makes it a preferred choice for demanding environments where traditional filter materials may not suffice.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português