Product Details

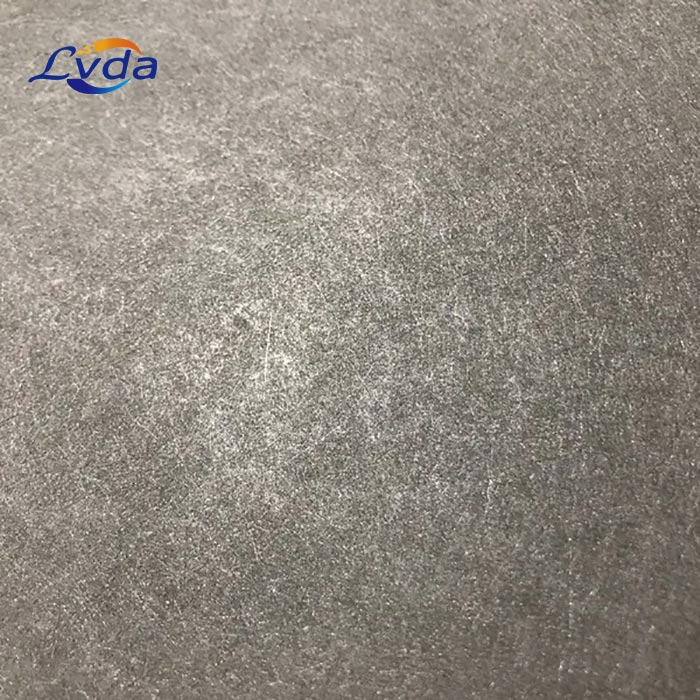

Titanium fiber felt is a high-performance material that is woven or combined with fine titanium fibers through a special process to form a nonwoven fabric. This material integrates many excellent properties of titanium metal, such as high strength, lightweight, good corrosion resistance, excellent high temperature resistance, and very good biocompatibility.

Manufacturing process : The production of titanium fiber felt typically involves high-precision fiber preparation techniques, including drawing titanium wires, cutting, and forming a felt-like structure through methods like needle punching and hot pressing. These processes require precise control to maintain the integrity of the titanium fibers and the uniformity of the felt material.

Ultra-thin high heat dissipation fuel cell gas diffusion layer titanium fiber felt is a specialized material designed to meet the specific needs of fuel cell technology, particularly in managing heat and facilitating gas diffusion efficiently. Fuel cells are devices that convert chemical energy from fuels into electrical energy through an electrochemical reaction, and they require effective management of heat and gases (such as hydrogen and oxygen) to operate efficiently and safely. The introduction of titanium fiber felt into this context brings several advantages due to its unique properties. Here's an overview of this innovative material:

Key Features

Ultra-thin design: This material is characterized by its ultra-thin profile, which is crucial for minimizing space usage within fuel cells without compromising their performance. The thinness enhances the overall compactness and can contribute to lighter fuel cell systems.

High heat dissipation: Titanium has excellent thermal conductivity, and when fabricated into a felt form, it provides a pathway for rapid heat dissipation. This is vital for maintaining the fuel cell's temperature within optimal operating ranges, thus ensuring efficiency and longevity.

Effective gas diffusion layer (GDL): The porous structure of the titanium fiber felt serves as an effective medium for gas diffusion. It ensures uniform distribution of reactant gases across the catalyst layer, thereby maximizing the reaction surface area and enhancing the electrochemical reaction efficiency within the fuel cell.

Corrosion resistance: Titanium's inherent corrosion resistance makes the ultra-thin high heat dissipation gas diffusion layer durable under the harsh chemical conditions often present in fuel cells, contributing to the overall durability and reliability of the system.

Lightweight and high strength: Despite its thinness, titanium fiber felt maintains a high strength-to-weight ratio, an essential attribute for mobile and stationary applications where weight and durability are critical factors.

Potential Applications

Fuel cells: In fuel cells, this material can serve as an efficient gas diffusion layer, facilitating the transport of hydrogen and oxygen to the reaction sites, while also managing the heat generated during the process.

High-performance electronics: The ultra-thin high heat dissipation property makes it ideal for use in electronic devices such as CPUs, GPUs, and power amplifiers, where efficient heat management is critical for performance and longevity.

Battery systems: In battery systems, especially those for electric vehicles and portable electronics, it can help manage the heat generated during charging and discharging, enhancing battery efficiency and safety.

Aerospace and automotive: Its lightweight, high strength, and thermal management capabilities make it suitable for aerospace and automotive applications, where weight reduction and efficient heat dissipation are crucial.

Medical devices: Given its biocompatibility and ability to manage heat and facilitate gas diffusion, this material can be used in medical devices that require strict temperature control and gas exchange.

Parameter

Material : Titanium

Temperature : ≤ 300°C

Thickness : 0.25mm, 0.4mm

Color : Metallic color

Shape : Square or round, customizable

Weaving mode : Fiber sintering

With the development of materials science and the increasing demand for high-performance materials, the application range of titanium fiber felts is expected to further expand. Researchers are exploring more cost-effective production processes, as well as new applications of titanium fiber felts in energy, environmental protection, bio-medicine and other fields. In addition, by compounding with other materials, the development of composites with more diverse functions and better performance is also an important development direction in the future.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português