Product Details

The plate and frame filter element is a filtering device. It is applicable to the closed filtration of liquid with concentration below 50% and low viscosity and slag content to meet the requirements of fine filtration and semi fine filtration such as purification, sterilization and clarification. Microporous membrane can be directly selected to achieve the purpose of aseptic filtration without microporous membrane filter.

Working principle of plate and frame filter element: The floating liquid is pumped into each sealed filter chamber of the filter. Under the action of working pressure, the filtrate passes through the filter membrane or other filter materials and is discharged through the liquid outlet. The filter residue is left in the frame to form a filter cake, so as to achieve solid-liquid separation.

Except for the motor, the plate and frame filter element is made of 1Cr18Ni9Ti corrosion-resistant stainless steel, which is suitable for filtering various PH value acid and alkali solutions. The plate and frame filter shall be pressurized and sealed for filtering, with less filtrate loss, good filtering quality and high efficiency. The filtering part is composed of nine filter plates, with large filtering area and large circulation; In addition, different filter membranes can be replaced according to the requirements of different production processes (primary filtration, semi fine filtration and fine filtration) of the filtered solution, and the number of filter plates can be appropriately reduced or increased according to the size of the user's production flow to meet the production needs. Therefore, the plate and frame filter has the characteristics of one machine with multiple uses and a wide range of applications; The filter plate is of plane thread mesh shape, with advanced structure, no deformation and easy cleaning, which can effectively increase the service life of various filter membranes, thus reducing and saving production costs. The plate and frame filter is equipped with stainless steel infusion pump, which is equipped with small motor and low power consumption.

Product features

1. Corrosion resistant and durable.

2. The filter plate adopts a threaded mesh structure. Different filter materials can be changed according to the requirements of different filter media and production processes (primary filtration, semi precision filtration, and precision filtration). The purpose of sterile filtration can be achieved by directly using microporous membrane. Users can also reduce or increase the number of filter layers according to the size of the filter volume to make it suitable for production needs.

3. All sealing parts adopt silicone rubber sealing rings, which are high temperature resistant, non-toxic, leak free and have good sealing performance.

4. The pump (or explosion-proof motor can be used) of the plate and frame filter and the input pipe components are connected in a quick way, which is convenient for disassembly and cleaning. The plate and frame filter has large filtering area, large flow and wide application range, so it is widely used in pharmaceutical, chemical, food and other industries, and has good effect in the filtration of pharmaceutical injection liquid

Product parameters

Model: | AAP0540009-00089 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 6000- 8000h |

Certificate: | ISO9001:2015 |

Quality: | 100% Tested |

Length: | 23.5 |

Outer Diameter: | 23.5 |

Inner Diameter: | 1.5 |

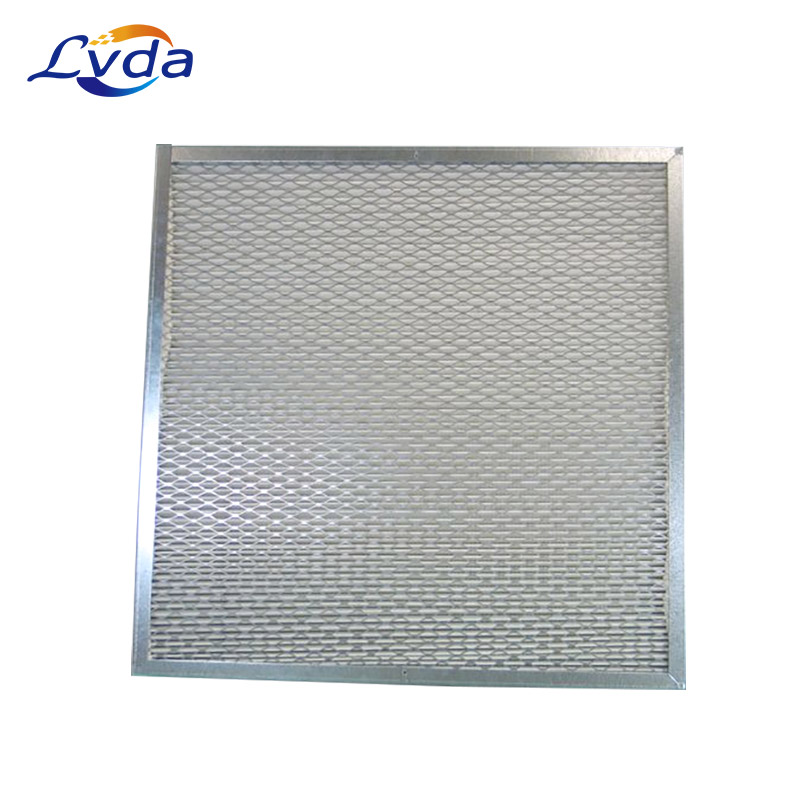

Filter Type: | Air Panel Filters |

Filtration Selectivity Raring: | 15 MICRON |

Maximum Flow: | 2500 SCFM |

Operating Temperature Range: | 200 F MAX |

Initial Differential Pressure: | 0.5" WC |

Center Tube: | N/A |

End Caps: | N/A |

Jacket: | EXPANDED METAL |

Handle: | NYLON OR STEEL STRAP |

Gasket: | N/A |

Product application

1.Hydraulic Engineering Systems Industry;

2.Mining and Metallurgical Equipment Industry;

3.Construction, engineering machinery industry;

4.Machine Tool Industry;

5.Agricultural machinery industry;

6.Plastic machinery industry;

7.Petrochemical industry;

8.Ship and marine engineering equipment industry.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português