Product Details

Fuel filter.

The fuel filter is connected in series on the pipeline between the fuel pump and the oil inlet of the throttle valve body. The function is to remove the iron oxide, dust and other solid impurities contained in the fuel and prevent the fuel system from being blocked (especially the fuel injection nozzle). Reduce mechanical wear, ensure stable engine operation and improve reliability. Recommended replacement cycle: once every 10000km.

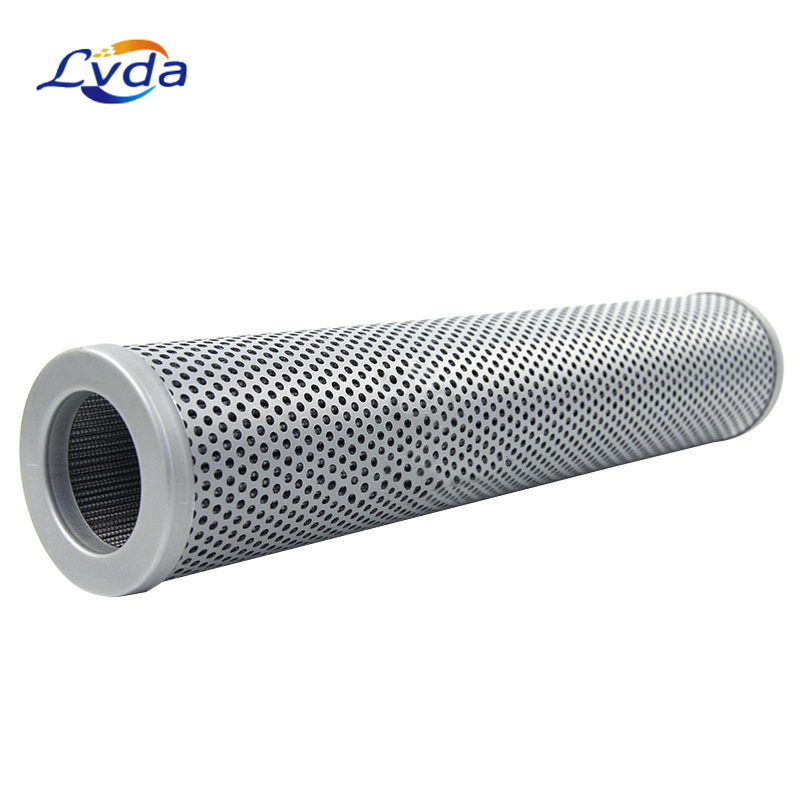

Oil filter

During engine operation, metal wear debris, dust, carbon deposit oxidized under high temperature, colloidal sediment, water, etc. are constantly mixed with engine oil. The role of the oil filter is to filter out these mechanical impurities and gums, keep the oil clean, and extend its service life and engine life. Recommended replacement cycle: once every 5000-8000km.

Product features

1: It can filter solid pollutants with fast speed and high efficiency (βx(c) ≥1000) to better protect various control valves in the system.

2: The filter material is made of patented glass fiber and resin through a unique process. Has a fixed void structure. The fiber does not fall off. The intercepted object will not "penetrate" the filter layer due to the "pulsation" of the pressure difference and flow.

3: The filter material adopts gradually shrinking pore size structure from outside to inside along the direction of liquid flow to intercept pollutant particles of different sizes in layers to achieve deep dirt retention and greatly increase the service life.

4: Professional pleated technology production maximizes the filtration area, increases the flow processing capacity, and creates a uniform flow distribution.

5: Anti-impact fatigue filter material to improve the stability of fluid cleanliness. Improve filtration performance under harsh conditions on site.

6: Antistatic structure minimizes the generation and discharge of static charge and prevents static electricity from destroying filter elements and filter media.

7: The long service life saves costs and reduces the number of waste filter elements to be processed, which is energy-saving and environmentally friendly.

Product parameters

Model | SH55153 |

Place of Origin | Henan, China |

Brand Name | LVDA |

Life span | 2000- 4000h |

Certificate | ISO9001:2008 |

Quality | 100% Tested |

Seal ring material | Nitrile rubber or fluorine rubber |

Filter element height | 82 mm |

Filter element diameter | 45 mm |

Expanded area of filter layer | 0.052s sq |

Pollution holding capacity | 14 g |

Medium flow direction | Outside → inside |

Bonding material | Epoxy adhesive |

Temperature range | Nitrile rubber seal-43ºC~+107ºCViton seal-29ºC~+120ºC |

Filter material | Inert gradual diameter arrangement glass fiber filter material, filament fiber non-woven fabric, stainless steel woven mesh |

Filtration accuracy | 1-100(Universal product filter element 10μm, can also be manufactured according to customer requirements) |

Filter ratio β value | ≥1000 βx(c) |

Working pressure difference | 0-4 bar |

Filter element ultimate pressure difference | ≤4 bar |

Product application

1.Automotive

2.Heavy-duty on-highway transportation

3.Commercial trucks and buses

4.Agriculture

5.Construction

6.Industrial

7.Marine

8.Mining

9.Oil & Gas

10.Power Generation

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português