Product Details

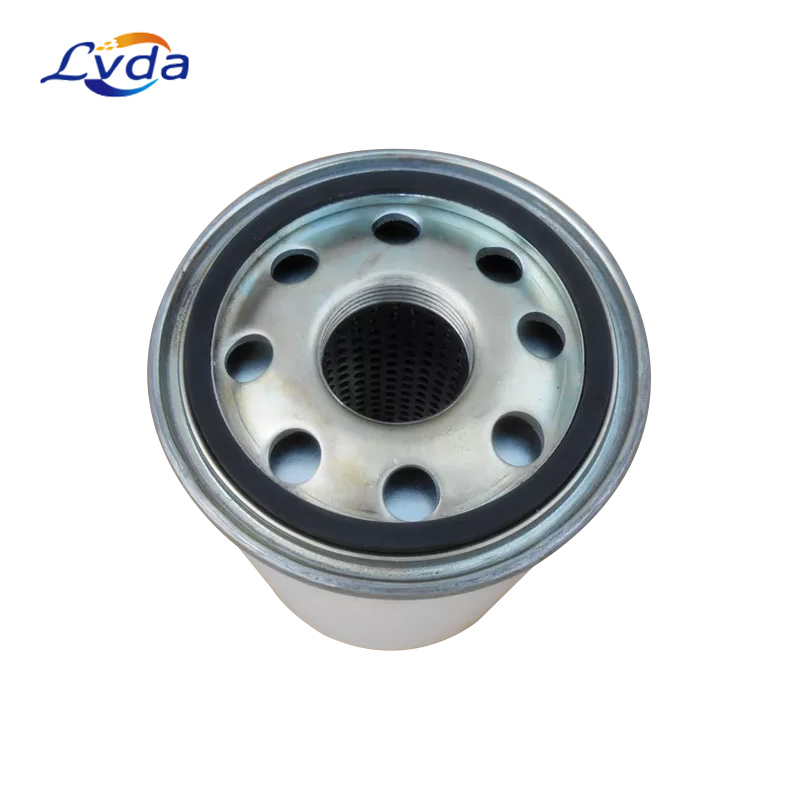

The filter is an indispensable device on the medium transmission pipeline. It is usually installed at the inlet of the pressure reducing valve, relief valve, constant level valve or other equipment to eliminate impurities in the medium and protect the normal use of the valve and equipment. When the fluid enters the filter cartridge with a filter screen of a certain size, its impurities are blocked, and the clean filtrate is discharged from the filter outlet. When cleaning is required, just take out the removable filter cartridge and reload it after treatment. Therefore, it is very convenient to use and maintain.

According to the different filtering accuracy (particle size of impurities filtered), the oil filter can be divided into four types: coarse filter, ordinary filter, precision filter and special fine filter, which can filter more than 100 μ m、10~100 μ m、5~10 μ M and 1-5 μ M size impurities.

When selecting filters, the following points should be considered:

(1) The filtering accuracy shall meet the predetermined requirements

(2) Capable of maintaining sufficient flow capacity for a long time

(3) The filter element has sufficient strength and will not be damaged by hydraulic pressure

(4) The filter element has good corrosion resistance and can work at the specified temperature for a long time

(5) Easy to clean or replace filter element

Therefore, the model of the oil filter shall be selected according to the technical requirements of the hydraulic system, filtering accuracy, flow capacity, working pressure, oil viscosity, working temperature and other conditions.

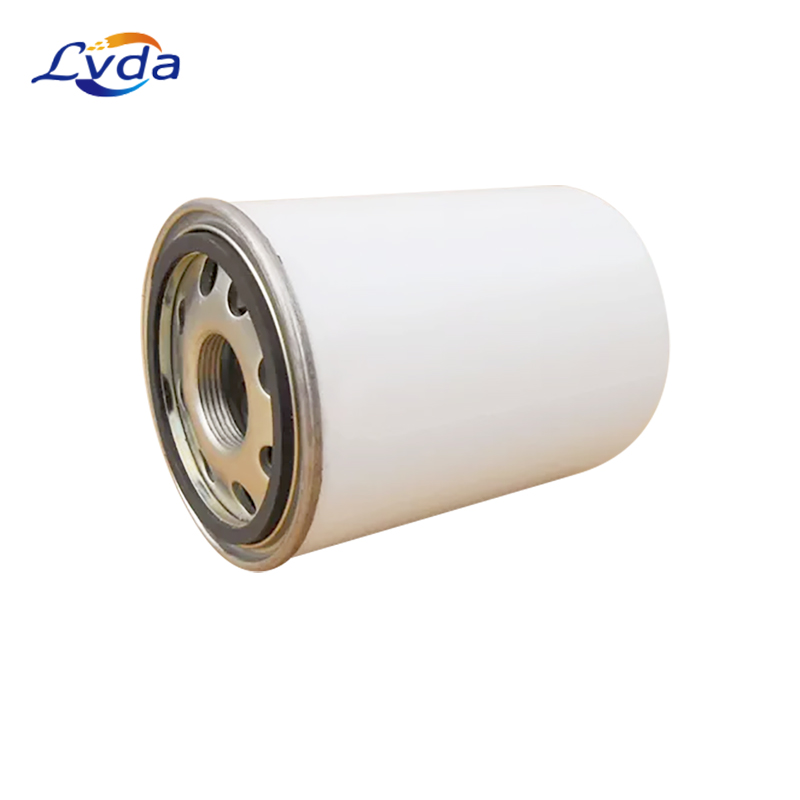

Product features

1.LVDA hydraulic filter element has high porosity, good permeability, small resistance and low differential pressure

2. It has high temperature resistance, corrosion resistance and is suitable for filtering highly viscous liquid.

3. The filtering area is large and the dirt holding capacity is large.

Product parameters

Model: | A-1-21-G10 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 2000- 4000h |

Certificate: | ISO9001:2015 |

Quality: | 100% Tested |

Weight | 1 kg |

Operating temperature: | up to 100°C |

Filter material: | Glassfiber, wire mesh, paper |

Outer diameter | 5.08 in |

Inner diameter | G11/4 |

Length | 9.02 in |

Media type | INORGANIC FIBERGLASS |

Efficiency | 10 um(c) βxz 200 |

Efficiency 1 | 12 μm(c) βx≥1000 |

Max working pressure | 174 psi |

Seals | NBR |

Product application

1. In the machine tool industry, at present, 85% of the machine tool transmission systems use hydraulic transmission and control. Such as grinder, milling machine, planer, broaching machine, press, shear, and modular machine tools.

2. In metallurgical industry, electric furnace control system, rolling mill control system, open hearth charging, converter control, blast furnace control, strip deviation and constant tension device all adopt hydraulic technology.

3. Hydraulic transmission is widely used in construction machinery, such as excavators, tire loaders, truck cranes, crawler bulldozers, tire cranes, self-propelled scrapers, graders and vibratory rollers.

4. In agricultural machinery, hydraulic technology is also widely used, such as combine harvesters, tractors and plows.

5. In the automotive industry, hydraulic off-road vehicles, hydraulic dump trucks, hydraulic aerial working vehicles and fire engines all use hydraulic technology.

6. In the light textile industry, hydraulic technology is applied to plastic injection molding machine, rubber vulcanizing machine, paper machine, printing machine and textile machine, etc

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português