Product Details

The main advantages of spin-on filters are the easy and quick replacement of the exhausted cartridge and the reduction of maintenance costs. Moreover Spin-on configuration is strategic when the machines involved in the maintenance operate in particularly contaminated contexts and difficult environmental conditions.

Donaldson lube filters are designed to keep today’s engine lube systems functioning at peak performance.

• Keep oil clean by capturing contaminants that cause engine damage.

• Include heavy duty components that are built to perform, built to last.

• Deliver essential engine protection for maximum cold flow performance.

Product features

1.Compact design and quality construction

2.Easy to install

3.Rapid to replace

4.Optimal performance in any operational and environmental context

Product parameters

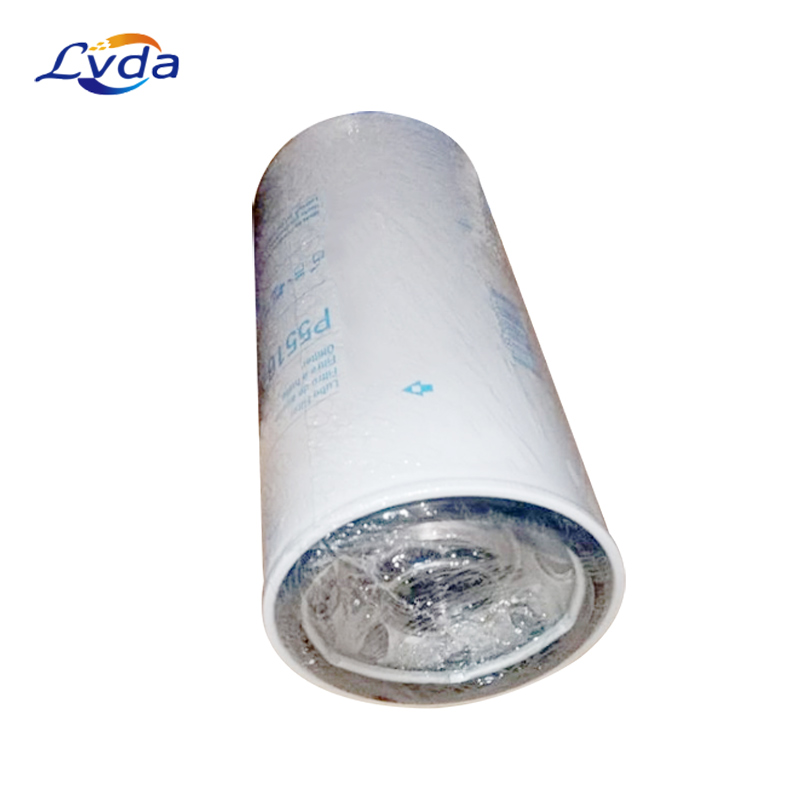

Model | P551670 |

Place of Origin | Henan, China |

Brand Name | LVDA |

Life span | 4000H |

Certificate | ISO9001:2015 |

Quality | 100% Tested |

Outer Diameter | 118 mm (4.65 inch) |

Thread Size | 1 1/2-12 UN |

Length | 260 mm (10.24 inch) |

Gasket OD | 110 mm (4.33 inch) |

Gasket ID | 98 mm (3.86 inch) |

Efficiency 99% | 21 micron |

Efficiency Test Std | SAE J1858 |

Media Type | Cellulose |

Collapse Burst | 10.3 bar (149 psi) |

Type | Full-Flow |

Style | Spin-On |

Primary Application | CUMMINS 3313279 |

Product application

1. Metallurgy: It is used for filtering the hydraulic system of steel rolling mill and continuous casting machine and filtering various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in oil refining and chemical production, particle removal and filtration of oilfield well water and natural gas.

3. Textile: purification and uniform filtration of polyester melt during wire drawing, protective filtration of air compressor, oil and water removal of compressed gas.

4. Electronics and pharmacy: pretreatment filtration of reverse osmosis water and deionized water, pretreatment filtration of cleaning solution and glucose.

5. Thermal power and nuclear power: purification of lubricating system, speed control system and bypass control system oil of gas turbine and boiler, and purification of feed pump, fan and dust removal system.

6. Mechanical processing equipment: lubrication system and compressed air purification of paper machinery, mining machinery, injection molding machines and large precision machinery, and dust recovery and filtration of tobacco processing equipment and spraying equipment.

7. Railway internal combustion engine and generator: filtering of lubricating oil and engine oil.

8. Automobile engine and construction machinery: air filter, oil filter, fuel filter for internal combustion engine, various hydraulic oil filters, diesel oil filters and water filters for construction machinery, ships and trucks.

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português