Product Details

It is well known that the compressed air coming out of the air compressor contains a large amount of oil, moisture, and impurity particles. The compressed air must be dried and purified before it can be used for gas supply. The compressed air system includes air compressors and gas storage. Tanks, precision filters and dryers, compressed air purification equipment refers to precision filters and dryers. The compressed air precision filter mainly filters solid particles in compressed air and has a certain blocking effect on liquid water and oil. Generally, three precision filters are installed at the front end of the dryer, which is mainly used to remove oil and impurity particles in the compressed air. A high-efficiency precision filter is installed at the rear end of the dryer, which is mainly used to remove fine dust in the compressed air.

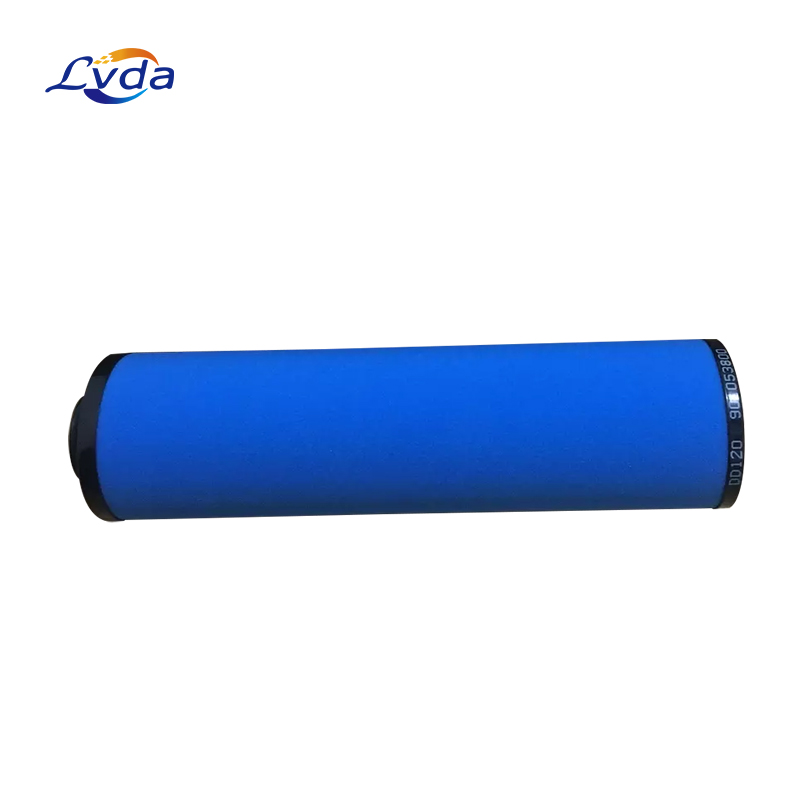

Specifications DD Series Replacement: The DD range of coalescing filters for general-purpose protection removes liquid water and oil aerosols to 0.1 mg/m_ (0.1 ppm) and particles down to1 micron. Particulate (After-Filter) Filters A particulate filter, also known asan after-filter, is usually located just after the desiccant air dryer to remove harmful liquid oil, water condensate, pipe scale,dirt and rust from your compressed air system. This helps prevent contaminants & corrosive damage to compressed air equipment and finished products. If the particulate filter gets soiled more frequently than what is typical for your environment, it may be time to replace the desiccant.

Product features

1.Good precision filter permeability.

Filter using the United States strong hydrophobic oil-thin fibrous filter, and use good permeability and high strength of the skeleton, reducing the resistance caused by crossing.

2.Good precision filter efficiency.

Filter with a German fine-hole sponge, can effectively prevent high-speed air entrainment of oil and water to go down the small oil droplets gathered to the bottom of the filter sponge, and row to the bottom of the filter container.

3. Good precision filter airtight.

The combination of filter and filter shell with a reliable seal ring to ensure that air is not short-circuit, to prevent impurities without going through the filter directly into the downstream.

4. Good precision filter corrosion resistance

The filter is made of corrosion-resistant reinforced nylon end caps and anti-corrosive filter cartridges for use in harsh conditions.

Product parameters

Model | DD120 |

Place of Origin | Henan, China |

Brand Name | LVDA |

Life span | 6000- 8000h |

Certificate | ISO9001 |

Quality | 100% Tested |

Material | Glass Fiber Filter Paper |

Application | AIR FILTER |

Maximum Oil Carryover | 0.1 ppm Oil Removal |

Micron Rating | 1Micron |

Outer Diameter | 86 mm |

Inner Diameter | 38 mm |

Length | 299.5 mm |

Media Type | Polyester Needle Felt |

Flow Direction | IN-OUT |

Seal | Nitrile |

Temperature Range | +1 - +60°C |

Product Net Weight (WEIGHT) | 0.5 Kg |

Grade | Filtration rating | Oil content |

DD | 1µ | 1ppm |

DDP | 1µ | dust removal |

PD | 0.01µ | 0.01ppm |

QD | 0.01µ | 0.003ppm (activated carbon) |

Model | Flow Rate NM3/min |

9 | 0.5 |

17 | 1 |

32 | 2 |

44 | 2.6 |

60 | 3.6 |

120 | 7.2 |

145 |

|

150 | 9 |

175 | 10.5 |

260 | 15.6 |

390 | 23.4 |

520 | 31.2 |

780 |

|

Product application

1.Metallurgy:

2. Petrochemical

3. Textiles, electronics and pharmaceuticals

4. Power Plant

5. Steel mills

6. Subway engineering

7. Chemical plant

8. Ships

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português