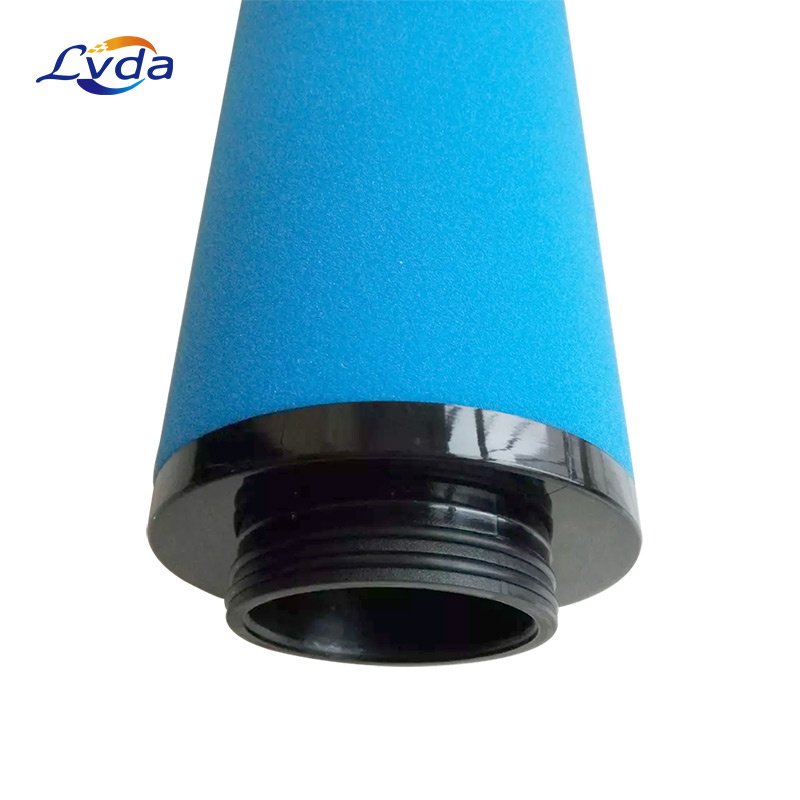

Product Details

- main pipeline filter

Protect the system as much as possible after the cooler in the air compressor or after the freeze dryer and other filters.

- air line filter

The apparatus removes moisture and particles in the form of tools, machinery, motors, cylinders, and a class of ultra high efficiency oil removal filters, or adsorption dryers.

- high efficient filter for eliminating oil

Often used upstream of an adsorption dryer or downstream of a refrigeration dryer to ensure that the air used in the system is completely oil-free.

Air compressed filter element can filter out contaminants such as rust, pipe scale,compressor lube oil, and water from compressed gases. Media choices range is high-temperature coalescers through bulk liquid removal, particulate-removal, and oil vapor (odor) removal filter elements.

Air compressed filter element offers a range of filtration and separation solutions that are designed to meet the needs of global clients through a dedicated focus on key market sectors. If you are interested in our products. Welcome to contact us anytime. We are online 24 hours a day.

Product features

1.Ideal filtration and discharge effect of oil mist, wet dust and water

-The efficient glass fiber Nautilus Nautilus technology can carry out efficient filtration and ensure the loss of low pressure drop at the same time;

2.Specially designed drainage technology

The 3D structure design of the end cover at the bottom of the filter element ensures the efficient separation and discharge of oil-water impurities, and prevents the separated oil-water impurities from entering the air flow again;

3.Reduce operation cost

-Reasonable design and filtration technology ensure low pressure drop loss;

4.Convenient maintenance

-The shell with rib design is convenient for disassembly;

-The design and replacement of push in filter element and integrated drain valve are simple;

-The maintenance indicator shows the use status of the filter;

Product parameters

Model: | 2901200308 |

Place of Origin: | Henan, China |

Brand Name: | LVDA |

Life span: | 6000- 8000h |

Certificate: | TS16949/ISO9001:2015 |

Efficiency: | 99.99% |

Quality: | 100% Tested |

Material: | Fiberglass,wire mesh etc. |

Type: | line filter |

Filtering precision: | 0.01~3 μm |

Thread Size | Standard size |

Weight: | 1-2kg |

Body Height (H-0) |

420 mm |

Height-1 (H-1) |

15 mm |

Total Height (H-TOTAL) |

435 mm |

Product Net Weight (WEIGHT) |

0.85 Kg |

Inner Diameter 1 (Ø 1 IN) |

60 mm |

Outer Diameter (Ø OUT) |

100 mm |

Stat. HS-Code |

84149000 |

Product application

1. Metallurgy: It is used for the filtration of the hydraulic system of rolling mills and continuous casting machines and the filtration of various lubricating equipment.

2. Petrochemical: used for separation and recovery of finished products and intermediate products in the process of oil refining and chemical production, liquid purification, purification of magnetic tapes, optical discs and photographic films in manufacturing, oil field well injection water and natural gas for particle removal and filtration.

3. Textiles, electronics and pharmaceuticals

4. Power Plant

5. Steel mills

6. Subway engineering

7. Chemical plant

8. Ships

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português