Product Details

Dust is the compressor's biggest enemy, causing wear and tear on compressor elements, valves, and other components. It will also destroy all moving parts of your compressor oil, oil separator, oil filter, etc. The air compressor inlet filter protects your compressor from outside dust and dirt.

Compressor air filters need to be cleaned and replaced regularly. Normally replacing the intake filter is part of the standard maintenance procedure. In a dusty/dirty environment, it's best to clean up once in a while.

Maximize air compressor lifespan

Dust and dirt contamination may cause damage or performance losses of rotors and their housings. Specific filter elements and high grade filtration efficiency guarantee your installation’s uptime. Built to withstand high operating pressures, our filters have a superior service life thanks to their high dirt holding capacity and temperature resistance.

Atlas Copco filter function(various series):

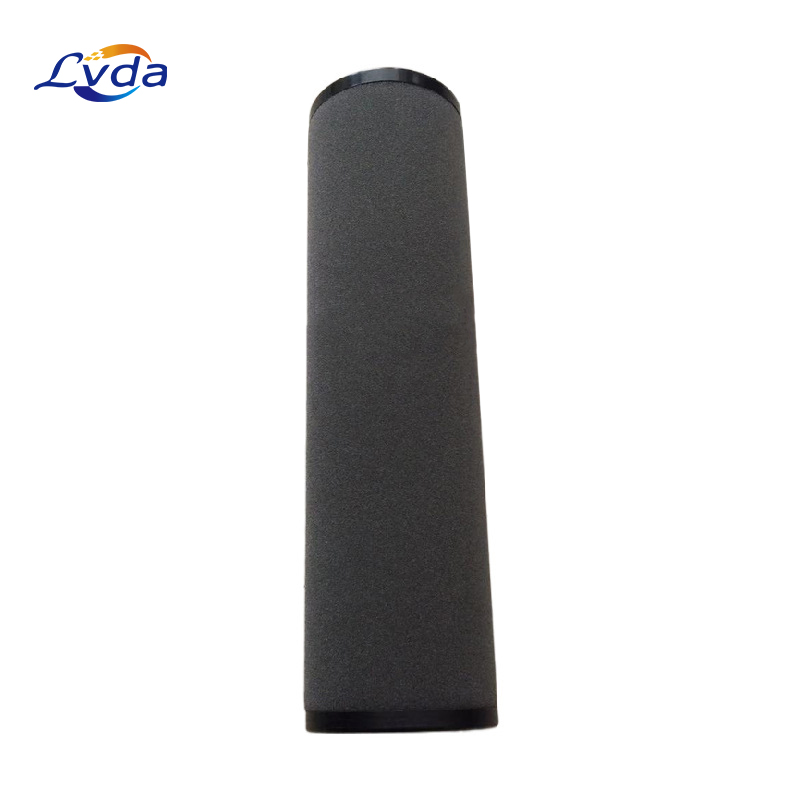

Filtering wet particles and greasy dirt: multi-layer wound filter element

The multi-layer wound filter element material has long-lasting good filtration performance in humid and oil-containing environments. Atlas Copco Nautilus technology and multi-layer wound filter element provide continuous and stable filtration performance, and the pressure is reduced, which has excellent performance in harsh use environments.

Filter solid dust particles: pleated filter element

For filtering dry solid dust particles in compressed air, the pleated filter element is an ideal filtering technology, with a large contact surface area to ensure a long service life of the filter element and low pressure drop loss.

Filter oil vapor:

Compared with conventional activated carbon filter media, activated carbon with microporous structure has larger surface area, excellent oil adsorption capacity and long-term stable filtration performance.

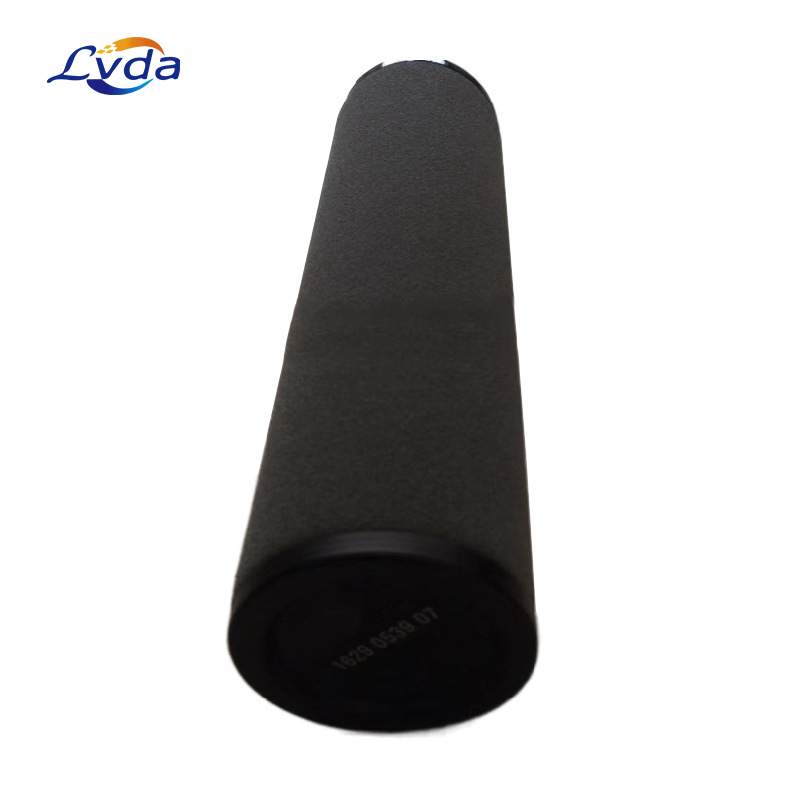

Product features

1.Maximum oil aerosol, wet dust and water droplet filtration and drainage

High- efficient glass fiber and foam media.

2.Significant energy savings & limited system operating costs

Optimal design and filter media allow low pressure losses.

3.High reliability

High- performance stainless steel cores, double O-rings,epoxy sealed caps, and anti-corrosive coated filter housing.

4.Easy maintenance

External ribs on the threaded housing,or a rotating bottom cover for the welded housings,and push-on elements.

5.Monitoring of energy use

Differential pressure indication (indicator for sizes 10-35 I/s,gauge for sizes 50 -8000 I/s) loptional for standard range).

Product parameters

Name | DDp+ | PDp+ | DD+ | PD+ | UD+ | QD+ |

DDp | PDp | DD | PD | QD |

Grade | Rough | Fine | Rough | Fine | Ultimate | Basic |

Contaminant | Dry dust | Oil aerosol/wet dust | Oil vapor |

FILTER SIZE

DD/PD | Nominal capacity | Reference

pressure | Maximum

pressure | Connections | Dimensions | Free space

for cartridge

replacement | Weight |

Standard | + | Standard | + | A | B | C | D |

l/s | cfm | l/s | cfm | bar(e) | psig | bar(e) | psig | in | mm | in | mm | in | mm | in | mm | in | kg | lbs |

215 | 170+ | 215 | 456 | 170 | 360 | 7 | 102 | 20 | 290 | 1-1/12 | 140 | 5.5 | 105 | 4.1 | 603 | 23.7 | 100 | 3.9 | 4.5 | 9.9 |

970F | 850+F | 970 | 2055 | 850 | 1801 | 7 | 102 | 16 | 232 | DN100 | 510 | 20.1 | 230 | 9.1 | 1360 | 53.5 | 1500 | 59.1 | 141.0 | 310.9 |

Product application

1.Pharmacy,

2.Chemical industry,

3.Environment protection

4.Spin,

5.Pneumatic conveying,

6.Pneumatic tools,

7.Aseptic packaging,

8.Plastic,

9.Chemical engineering,

10.Metalware,

11.Mechanical electromechanical,

12.Electronics,

13.Metallurgy

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português