Product Details

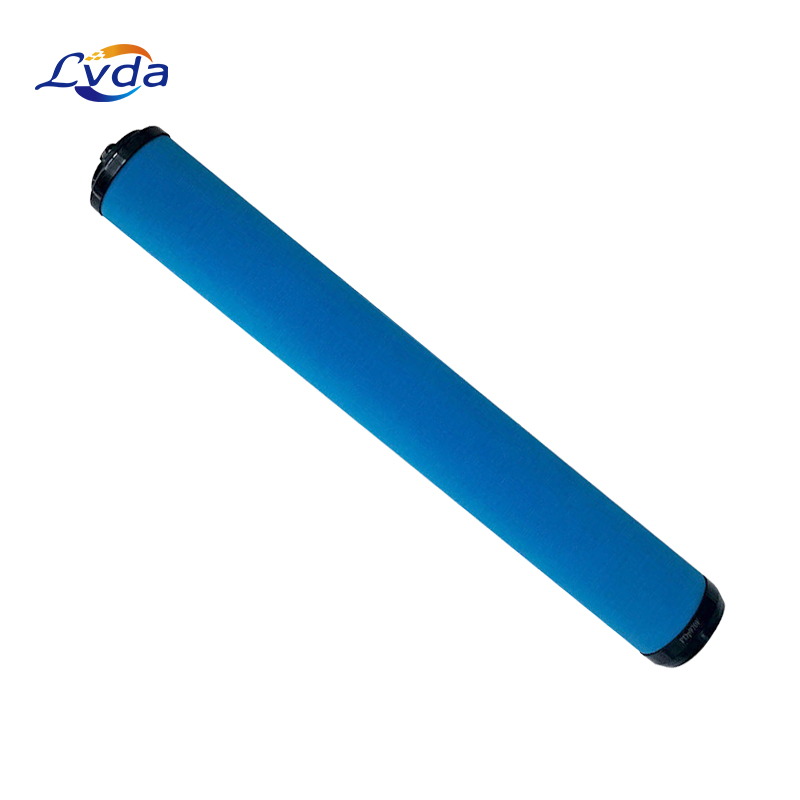

LVDA FILTER DD 970F air compressor precision filter element adopts high-quality filter materials and advanced manufacturing technology to ensure the filtering effect and service life. The filter element is mainly used for air purification and filtration, which can filter out water vapor, condensed water, atmospheric dust, mechanical impurities, oil mist and microorganisms in the air to ensure the purity of the air and make the air system operate normally. The filter element adopts borosilicate fiber filter material and porous glass fiber filter equipment. The outer layer is made of polyester fiber layer, which is resistant to high temperature and chemical corrosion, ensuring high efficiency filtration and minimum pressure loss. Equipped with various high-precision gas equipment, various first-line brand air compressors, post-processing, laser cutting equipment, instrument gas, medical equipment, food equipment, etc.

DD+ level

Coalescing filter for general protection, removing solid particles, liquid water and oil mist.

In order to obtain the best filtering effect, the DD+ filter should be before the water separator.

PD+ level

High-efficiency coalescing filter to remove solid particles, liquid water and oil mist.

For the best filtering effect, the PD+ filter should always be before the DD+ filter.

QD+ level

Activated carbon filter, used to remove oil vapor and hydrocarbon odor, the maximum residual oil content is 0.003 mg/m3 (0.003 ppm). 1,000 hours of service life.

Product features

1.Maximum oil aerosol, wet dust and water droplet filtration and drainage

High- efficient glass fiber and foam media.

2.Significant energy savings & limited system operating costs

Optimal design and filter media allow low pressure losses.

3.High reliability

High- performance stainless steel cores, double O-rings,epoxy sealed caps, and anti-corrosive coated filter housing.

4.Easy maintenance

External ribs on the threaded housing,or a rotating bottom cover for the welded housings,and push-on elements.

5.Monitoring of energy use

Differential pressure indication (indicator for sizes 10-35 I/s,gauge for sizes 50 -8000 I/s) loptional for standard range).

Product parameters

|

DD |

PD |

QD |

Particle retention |

0,1 µm |

0,01 µm |

activated |

carbon |

Solids - q. class (ISO 8573-1) |

2 |

1 |

1* |

Oils -q. class (ISO 8573-1) |

2 |

1 |

1 |

Filter media |

borosilicate |

activated |

microfibers |

carbon |

Operating temp. range[℃] |

1,5 to 65 |

1,5 to 65 |

1,5 to 45 |

Diff. pressure (new) [mbar] |

50 |

80 |

60 |

Product application

1.Pharmacy,

2.Chemical industry,

3.Environment protection,

4.Spin,

5.Pneumatic conveying,

6.Pneumatic tools,

7.Aseptic packaging,

8.Plastic,

9.Chemical engineering,

10.Metalware,

11.Mechanical electromechanical,

12.Electronics,

13.Metallurgy

English

English اللغة العربية

اللغة العربية বাংলা

বাংলা Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Русский алфавит

Русский алфавит Español

Español اردو

اردو Português

Português